The WOODWARD 9907-164 is part of the microprocessor based 505 and 505E governor control unit.The following is a detailed description of the product:

1.Basic Information

Model:9907-164

Brand:WOODWARD

Series:505/505E series speed controller control unit

2.Technical Specifications

Function:Operate steam turbine,turbogenerator and turboexpander modules

Control module:Digital microprocessor controller

Operation mode:Control the steam turbine by operating the single extraction and/or intake of the steam turbine

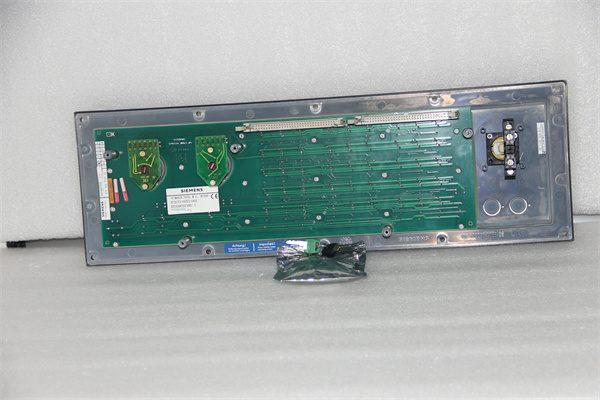

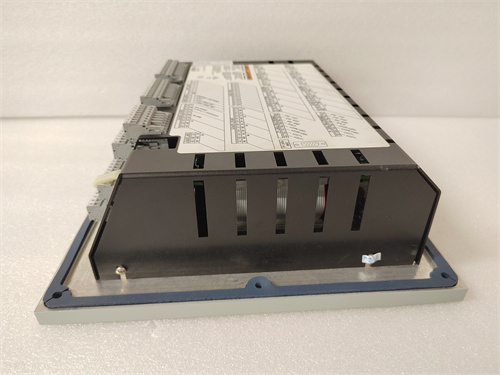

WOODWARD 9907-164

Actuator:Utilizes the turbine’s staged actuator(one or two)to actuate the steam inlet valve

Input/Output:

16 contact inputs(4 dedicated,12 programmable)

6 programmable current inputs(4 to 20 mA)

Display and Control:

The operator control panel on the front of the device can display two lines of text,24 characters per line

Menu driven software controlled and changed by the operator control panel

Standard Features:

Critical speed avoidance

Valve limiter

Automatic start sequence

Stop first out indicator

Communication interface:support Modbus protocol

Physical Specifications:

Dimensions:14″W x 11″H x 4″D

Operating temperature:-4 to+140 degrees Fahrenheit(or-20 to+60 degrees Celsius)

Storage Temperature:-40 to+185 degrees Fahrenheit(or-40 to+85 degrees Celsius)

Input voltage:+24 Vdc,1 A

WOODWARD 9907-164

3.Product Features

High-precision control:Using advanced digital microprocessor technology to achieve precise control of fan speed,load and other parameters.

Rich control functions:including speed control,load control,compressor and turbine start and stop control,etc.,to meet the control requirements under various complex working conditions.

Data collection and monitoring:Capable of collecting and monitoring data related to turbine performance,such as speed,temperature,pressure,etc.,to ensure that the turbine operates within a safe and effective working range.

Self-diagnosis and fault detection:With self-diagnosis function,it can detect turbine faults and issue alarms,thus improving the reliability and safety of the system.

Highly Flexible:As with any 505 speed controller module,the device can be configured and changed in the field by the field operator through menu-driven software integrated into the operator control panel on the front of the device.

The company mainly imports PLC modules, programmable controllers, servo control systems and DCS spare parts, such as ABB, AB (Rockwell), GE (General Electric), Bentley, Honeywell, Emerson, Motorola, Invensys, Westinghouse Electric, etc. The company has established close cooperative relationships with many world-renowned PLC and DCS product maintenance service providers. We can directly purchase goods from abroad and provide equipment and spare parts from different countries and manufacturers.

We supply directly from abroad without any middlemen, which reduces the cost of use.

There really is no medium that can make a difference!!

Shenzhen Changxin Automation – Abundant stock, large quantity of现货, quality guaranteed. You can purchase and use with confidence!

If you have any defects or demands for imported PLC and DCS spare parts, please contact our team. We will quickly help you find reliable and high-quality products, shorten the delivery time, and ensure that your equipment operates normally in the appropriate environment. Just in time.

We specialize in providing: Programmable Logic Controller (PLC) control systems, Distributed Control Systems (DCS), Safety Instrumented Systems (SIS), Emergency Shutdown (ESD) systems, vibration monitoring systems, Turbine Compressor Control Systems (CCS), and other PLC modules, various industrial control systems, system modules, CPUs, IO modules, DO modules, AI modules, DI modules, network communication modules, Ethernet modules, motion controllers, analog input modules, analog output modules, digital input modules, digital output modules, module redundancy, power modules, relay output units, relay input units, and processor units.

Our products are widely applied in modern industrial fields such as power, petroleum, mine hoisting, ports, heating, gas supply, water supply, sewage treatment, metallurgy, papermaking, textile, chemical engineering, and water conservancy!

“Power plant DCS monitoring system”

“Manufacturing of Intelligent Flat Plate Tempering Furnace System”

“PLC Programmable Drive Control System”

“DCS Distributed Control System”

5. “Intelligent Fire Water Supply System”