PROSOFT MVI46-MCM is a communication module designed for industrial automation applications.The following is a detailed introduction to the module:

1.Basic Information

Brand:ProSoft Technology

Model:MVI46-MCM

Function:Modbus communication module

2.Key Features and Functions

Interface and protocol support:

Equipped with 2 Ethernet ports and 1 serial port,it supports multiple Modbus protocols,including Modbus TCP/IP,RTU,ASCII and DF1,and can adapt to various communication environments and requirements.

Design features:

The modules are compact and designed to withstand harsh industrial environments.

The temperature range is-40°C to+85°C(some data indicate an operating temperature of 0°C to 60°C and a storage temperature of-40°C to 85°C,which may be related to the specific application scenario or product batch),and it is UL/cUL,ATEX and IECEx certified,which means it can be safely used in hazardous locations.

Diagnostic functions:

Equipped with advanced diagnostic functions,such as real-time monitoring of Modbus communications,it helps to quickly identify and troubleshoot communication problems,improving system reliability and maintenance efficiency.

Main processor and working mode:

The main processor is 32-bit,runs at 50Hz,and uses a 3-2-1-0 working mode.

3.Application and Compatibility

Application areas:

Widely used in industrial automation applications that require Modbus communication,such as oil and gas,sewage industry,food processing,petrochemical industry,pulp and paper,etc.

compatibility:

It can easily connect with Allen-Bradley SLC processors,ControlLogix processors and other Modbus protocol compatible devices,acting as a gateway between the Modbus network and the processor backplane.

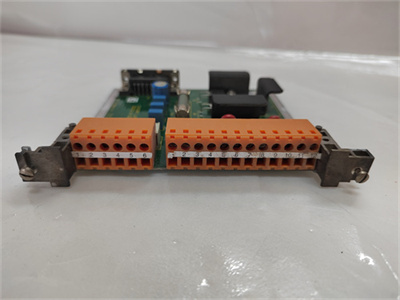

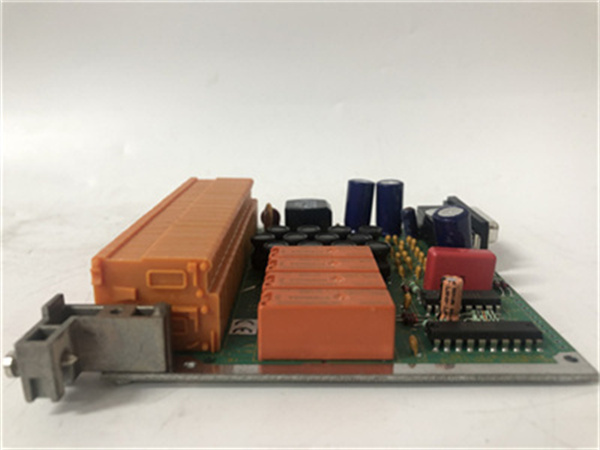

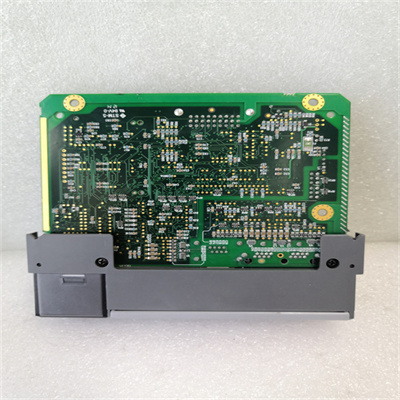

4.Hardware specifications and configuration

Hardware specifications:

Single slot module,can be directly installed on the corresponding backplane(such as 1746 backplane).

With RJ45 debug and configuration port,and RJ45 RS-232/422/485 application combo port.

LED indicators are provided for module status,backplane transmission status,application status,serial activity,and error status.

Memory and registers:

The internal register space is used for data exchange between the processor and the Modbus network,supporting the storage and transmission of large amounts of register data.

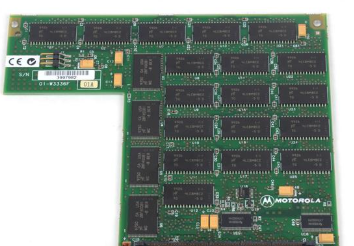

The company mainly imports PLC modules,programmable controllers,servo control systems and DCS spare parts,such as:ABB,AB(Rockwell),GE(General Electric),Bentley,Honeywell Er),Emerson.),Motorola,Invensys,Westinghouse,etc.The company has established close cooperative relations with many world-renowned PLC and DCS product maintenance service providers.We can purchase goods directly from abroad and provide equipment and spare parts from different countries and manufacturers.

We supply goods directly from abroad,without intermediaries,reducing the cost of use.

There is really no medium that can make a difference!!

Shenzhen Changxin Automation-sufficient supply,large spot quantity,guaranteed quality,you can buy with confidence and use with peace of mind~!

If you have any defects or needs for imported PLC and DCS spare parts,please contact our team,we will help you find reliable and high-quality products super quickly,while shortening delivery time to ensure that your equipment can operate normally in the right environment.Just in time.

Professionally provide:PLC programmable control system,distributed control system(DCS),safety instrument system(SIS),ESD system,vibration monitoring system,turbo compressor unit control system(CCS)and other PLC modules,various industrial control systems,system modules,CPU,IO module,DO module,AI module,DI module,network communication module,Ethernet module,motion controller,analog input module,analog output module,digital input module,digital output module,module redundancy,power module,relay output unit,relay input unit,processor unit.

Products are widely used in:electricity,petroleum,mine hoisting,ports,heating,gas,water supply,sewage treatment,metallurgy,papermaking,textile,chemical industry,water conservancy and other modern industrial fields!

1.”Power plant DCS monitoring system”

2.”Intelligent flat tempering furnace system manufacturing”

3.”PLC programmable transmission control system”

4.”DCS distributed control system”

5.”Intelligent fire water suppl