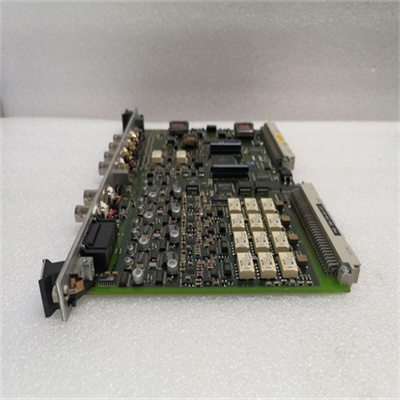

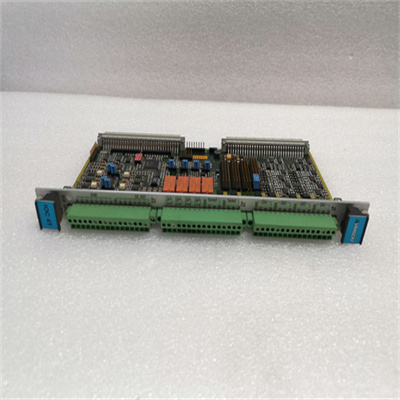

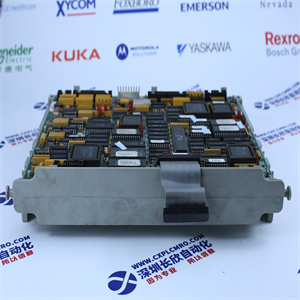

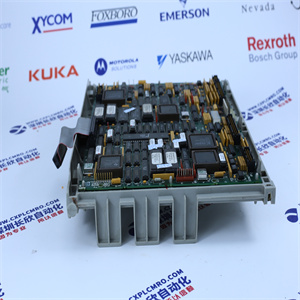

Product Parameters of Vibro-meter 200-510-041-021 200-510-111-021 VM600 MPC4:

- Input Channels: 4 dynamic channels and 2 tachometer (speed) channels1.

- Frequency Range: Not specified, but likely to cover the range of rotating machinery.

-

Vibro-meter 200-510-041-021 200-510-111-021 VM600 MPC4

- Measurement Range: Varies depending on the application, but typically includes vibration measurements2.

- Data Sampling Rate: High-speed sampling for accurate vibration monitoring.

- Working Temperature: -20°C to 60°C12.

- Storage Capacity: 10,000 data points12.

- Power Supply: 24VDC12.

- Dimensions: 210 x 170 x 75 mm12.

- Weight: 1.5 kg12.

- Protection Rating: IP2012.

- Signal Input: BNC connector12.

- Communication Interface: RS-48512.

Application Fields of Vibro-meter 200-510-041-021 200-510-111-021 VM600 MPC4:

- Rotating Machinery Monitoring: Widely used in industries such as power, oil & gas, chemicals, steel, and cement for monitoring the vibration of rotating machinery123.

- Fault Detection and Prevention: The ability to monitor vibrations allows for early detection of potential faults or failures, enabling proactive maintenance and reducing downtime1.

-

Vibro-meter 200-510-041-021 200-510-111-021 VM600 MPC4

- Centralized Monitoring Systems: Suitable for applications where multiple rotating machines are located in a centralized area, requiring a high channel count for comprehensive monitoring3.

- Critical Rotating Machinery: Especially suited for monitoring critical rotating machinery, such as gas turbines, steam turbines, and hydro turbines3.

- Integration with Software: Can be integrated with VibroSight software to provide detailed analysis and reporting of rotating machinery conditions3.

In summary, the Vibro-meter 200-510-041-021 200-510-111-021 VM600 MPC4 is a versatile vibration monitoring solution for a wide range of rotating machinery applications, enabling proactive fault detection and maintenance to improve equipment reliability and reduce downtime.

Vibro-meter 200-510-041-021 200-510-111-021 VM600 MPC4

Vibro-meter 200-510-041-021 200-510-111-021 VM600 MPC4 (2)

Reviews

There are no reviews yet.