Product Description

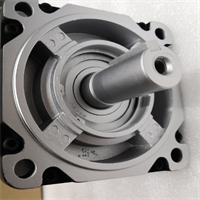

The MPL-B540K-SJ24AA/A A-B servo motor is used to drive mechanical equipment for precise position control.

feature

Single encoder(metasurface protocol)feedback

Integrated encoder supports HIPPER protocol

Rated speed

Continuous stall torque

The Rockwell Automation 165mm micro inertial AC motor is a compact servo with 4000 rpm.Its characteristic is single encoder(metasurface protocol)feedback.The AC synchronous servo motor is equipped with a 24VDC brake,if braking is required.In addition,this intelligent servo is equipped with a circular bayonet cable connector,which is built on this AC servo motor and comes with a voltage of 230 volts AC.This MPL series brushless motor also has a 4-inch length,a rated speed of 4000rPM,a single revolution high-resolution encoder feedback,shaft key/no shaft seal,circular bayonet,facing shaft,24V DC brake,information,communication,and standard specified options.

The MplB-540K-SJ-24AA servo motor is an AC motor with a frame length of 165mm.Its rated speed is 4000 revolutions per minute,belonging to the MPL series from Allen Bradley.The low inertia motor from the MPL series can support rated speeds of up to 8000rPM,output power of 0.16-18.6 kW,continuous stall torque of 2.3-1440 pounds,and peak stall torque of 6.6-2460 pounds.The input power of the MplB-540K-SJ24AA servo motor is 400 volts AC.The approximate weight of the servo motor is 33 pounds.The output power is 5.4 kilowatts.The rotor inertia is 0.014Lb for S2.The peak and continuous stall torque specifications of the MplB-540K-SJ24A servo motor are 420 pounds per inch and 172 pounds per inch,respectively.

The magnet stack length of MplB-540K-SJ24A servo motor is 101.6 millimeters.For feedback,the servo motor has a 1024Sin/CO absolute single rotation encoder.This integrated encoder supports the HIPPER protocol.The functions of other servo motors include a circular bayonet connector,a shaft key,a 24V DC brake,and an independent Election Committee metering flange.If a shaft seal is required,an optional sealing package will need to be ordered from Allen Bradley.The advantages of installing shaft seals include preventing particles and moisture,and reducing wear on motor bearings.The shaft seal should be lubricated together with the lubricant that comes with the shaft seal package.Due to the wear of the shaft seal,it is recommended to conduct regular inspections.Depending on their condition,the replacement frequency of the shaft seal varies from 3 months to 12 months.Third party manufactured shaft sealing devices should not be used with Allen Bradley motors.

application area

The MPL-B540K-SJ24AA/A A-B servo motor is widely used in fields such as automated production lines and robotics technology.

Reviews

There are no reviews yet.