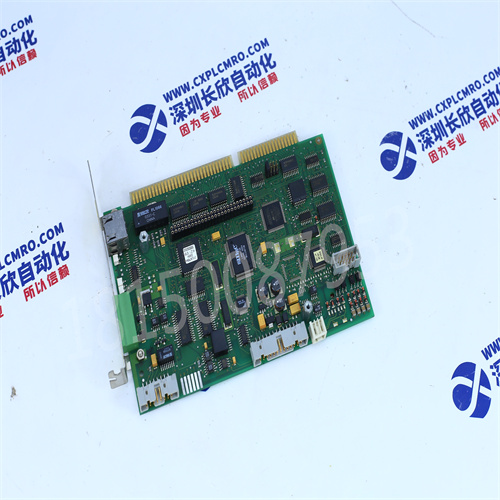

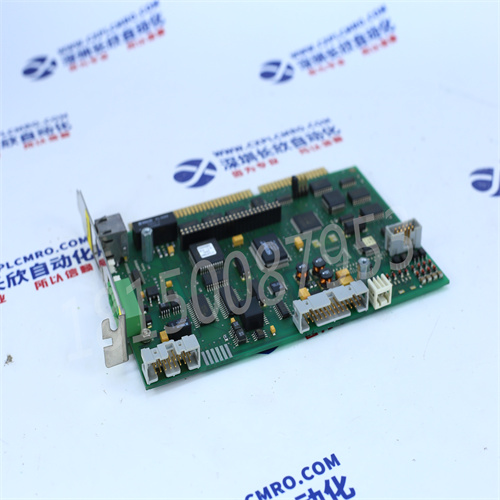

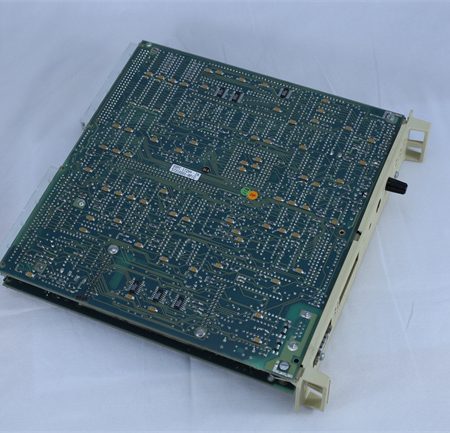

KUKA MFC2

The KUKA MFC2 (Motion and Force Control) is a software package designed for KUKA robots that allows for precise control of motion and force during robotic operations. It provides advanced control algorithms for tasks such as assembly, grinding, polishing, and deburring. The MFC2 software package includes features such as force sensing, impedance control, and compliance control, which enable the robot to adapt to changes in the environment and perform tasks with greater accuracy and efficiency. The software is compatible with KUKA’s KR C4 robot controller and can be used with a variety of KUKA robot models.

Product Information:

- Manufacturer: KUKA

- Product: Multi-Functional Controller 2 (MFC2)

- Type: Control system for robotic systems and peripherals

- Purpose: Provides control, coordination, and programming interface for robotics applications

Agilent 37718A Omni-Ber 718 Communications Performance

OptiSpec EKE Light source For Video Microscope QTYS 5

HP 81689A Tunable Laser module.w opt 072

Agilent 83481A Dual rate optical/electrical plug-in Opt

EFD Model 1500XL Adhesive Dispenser

TEKTRONIX ST2400 SDH/SONET SET WITH OPTION

Vytran PTR-100 Automatic Fiber Recoater

WaveSplitter 1×2 C-band Fused Fiber Coupler

Parameters and Features:

- Processing Power: The MFC2 is equipped with a powerful processing unit capable of handling complex calculations and real-time control tasks.

- Robot Control: It offers advanced control capabilities for KUKA robotic systems, enabling precise movement, path planning, and manipulation of robot arms.

- Communication Interfaces: The MFC2 supports various communication interfaces, allowing seamless integration with other devices and systems within the automation setup. It typically includes Ethernet, USB, serial interfaces, and digital I/O.

- Programming: The MFC2 supports programming using KUKA’s proprietary programming language called KRL (KUKA Robot Language). This language enables users to develop custom applications and control algorithms for specific automation tasks.

- Safety Features: The MFC2 incorporates safety features to ensure the protection of operators and equipment. It includes features such as emergency stop, safety sensors, and safety interlocks.

- Expansion Modules: The MFC2 can be expanded with additional modules to extend its capabilities. These modules may include input/output modules, additional communication interfaces, or specialized hardware for specific applications.

- User Interface: The MFC2 provides a user-friendly interface for easy operation and monitoring. This interface can be accessed via a touch panel display or a connected computer.

- Compatibility: The MFC2 is compatible with various KUKA robot models and can be integrated into diverse industrial applications such as manufacturing, assembly, material handling, and more.

Reviews

There are no reviews yet.