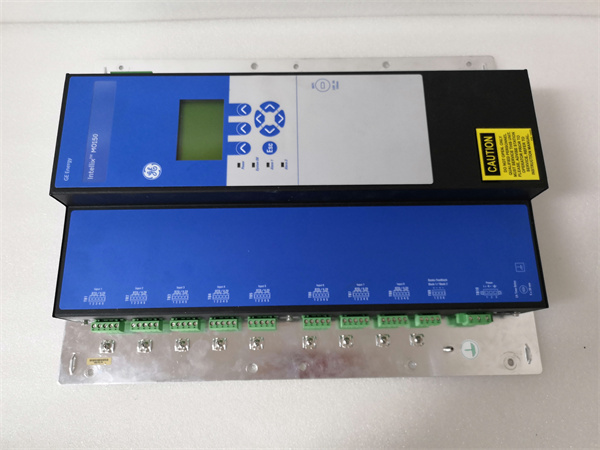

Product Description

The INTELLIX MO150 GE transformer monitoring system is used to monitor the status of transformers in real-time and prevent potential faults.

feature

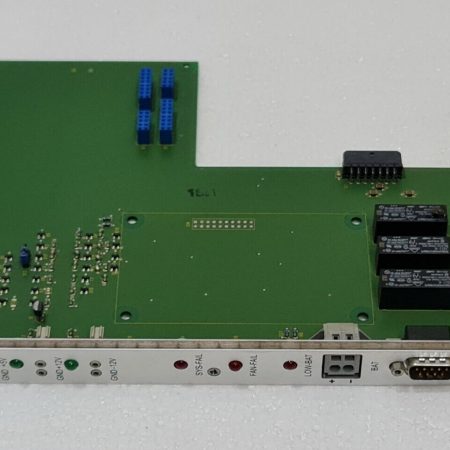

-8 analog inputs(4-20 mA or RTD PT100)

-5 AC inputs(load and fan current)

-2 digital inputs(system alarm,cooling control,and cooling alarm)

-Embedded function with transformer model-historical data collection

•One Hydran S2 gas and humidity sensor

Two magnetic mounted RTDs(top and bottom oil temperature measurement)

•One load current CT converter

•Multi host software(client user interface running on remote PC)

The Intellix MO150 monitoring package consists of an integrated system of sensors,analytical models,and data processing functions to address most common failure modes.This cost-effective software package provides the necessary condition assessment tools to achieve effective management and optimal utilization of this critical power plant component.

An Intellix MO150 system will be able to connect up to four Hydran S2 units and one Hydran M2 in a network.The mathematical model of the transformer will be calculated based on the Hydran device,which will be configured as the main fuel tank.The additional(optional)Hydran S2 equipment can only continuously measure the fault gases and smoke that may be generated in the transformer and its associated alarms online.

Online monitoring and real-time diagnosis of transformers can reduce the occurrence of sudden and catastrophic accidents.At the same time,it can avoid expensive replacement and cleaning costs,avoid unplanned power outages,and improve the overall level of assets.The reliability and potential failure monitoring of transformers are crucial for extending the lifespan of important transformers and have significant commercial and operational benefits:

Can increase the time interval between two routine inspections,reduce inspection and maintenance costs,optimize equipment life by monitoring cooling system performance

Continuous monitoring of transformer status to reduce unplanned power outages

Using online models to provide real-time transformer status information and better extend transformer life

Optimize transformer performance,extend transformer life,and delay transformer updates

The lntellix MO150 transformer monitoring system is an intelligent and cost-effective solution that can provide comprehensive monitoring and interactive status diagnosis for power equipment,and achieve real-time intelligent control.It is designed to collect,process,analyze data,and provide explanations for critical operations based on data obtained from various sensors.It integrates intelligent functions and can automatically calculate online transformer models based on IEEE and IEC standards using monitored transformer characteristics and real-time measurement data

The lntellix MO150 system is very easy to install on oil-filled electrical equipment,for online and continuous monitoring of the following new or long-term equipment:

power transformer

Autotransformer

Equipment Transformer

Electric arc furnace transformer

Rectifier transformer

distribution transformer

reactor

Lntellix M0150 is designed to collect,process,analyze data,and interpret critical operations based on data obtained from various sensors.It integrates intelligent functions and can automatically calculate online transformer models based on IEEE and IEC standards using the characteristics of monitored transformers and real-time measurement data.The online model system provided by this system is as follows:

·MVA model(calculating the apparent power of primary,secondary,or tertiary windings)

·Winding hot spot temperature model[calculating the hot spot temperature at the load current measurement point of each system group]

·Humidity and bubble model(calculating conductor insulation humidity and bubble generation temperature)

·Insulation aging model(calculating the aging acceleration factor specified in IEEE or EC guidelines)

·Humidity model for oil-paper insulation structure(calculating humidity in oil-paper insulation structure)

·Management and operation of transformer cooling system for cooling control model

·Cooling efficiency model[monitoring the actual efficiency of the cooling system]

·Thermal model of voltage regulating switch(calculating the temperature difference between LTC oil chamber and transformer oil tank)

·Voltage regulating switch position tracking model(recording and tracking the process of switch position changes)

·Dynamic load model(continuously estimating transformer load to ensure it is within a safe range under overload conditions)

And provide pre diagnosis and diagnostic modules to provide fault diagnosis suggestions in the event of transformer alarms,as well as prompts for possible problems that may arise if action is not taken on related faults,and recommends actions that should be taken.

application area

The INTELLIX MO150 GE transformer monitoring system is suitable for power supply systems that require precise monitoring of transformer status,such as power stations,factories,etc.

POLYEHTER POLYOL, CONVENTIONAL POLYOL, POLYOL 0%, POLYOL 3500MW, POLYOL 3000MW, WANOL F3156,LEP-5631, TEP-545SL, WANOL F3147, PPG 5631, WANHUA 3156, INOVOL F5631, GP-3000, FA-717, PPG-3022, PPG 3022, PPG-3322, PPG 3322, Y-5603, Y-4813, V-3022, CP-3322, CPS-3000, ARCOL-1108,LEP-5631

POLYOL 10%,POLYOLMER POLYOL 10%, POLYOLMER 10%, POLYMERIC POLYOL 10%, POLYMERIC 10%, WANOL F3110P, KE-1990, PPG-3600, PPG 3600, HL-106, ARCOL-1905,LPOP-2010

POLYOL 15%, POLYOLMER POLYOL 15%, POLYOLMER 15%, POLYMERIC POLYOL 15%, POLYMERIC 15%, WANOL F3115P, PPG-3601, PPG 3601, Y-1537, HL-109,LPOP-2015

POLYOL 25%, POLYOLMER POLYOL 25%, POLYOLMER 25%, POLYMERIC POLYOL 25%, POLYMERIC 25%, WANOL F3125P, KE-1950, PPG-3602, PPG 3602, Y-1564, HL-108, ARCOL-1366, LPOP-2025

POLYOL 45%, POLYOLMER POLYOL 45%, POLYOLMER 45%, POLYMERIC POLYOL 45%, POLYMERIC 45%, WANOL F3145P, WANOL F3148P, CS-743, Y-7930, V-3943A, HS-100, LH-50, LH-100, LH-200, LUPRANOL-4600, LHS-50, LHS-100

WANOL POP2045, WANOL POP2140, WANOL POP3630, WANOL POP3628, WANOL F3135, WANOL F3140, WANOL F3150, WANOL F3160, WANOL F3180, KE-878N, HL-400, INOVOL, PURANOL, WANOL, LUPRANOL, ARCOL

TDI:

Tolulene diisocyanates, TDI 80/20, WANHUA TDI, BASF TDI, HANWHA TDI, COVESTRO TDI, DAHUA TDI, JULI TDI, Lupranate TDI-80, WANATE TDI-80, WANNATE PM-200, WANNATE PM-100, 44V20L, M20S, 5005, Tolulene diisocyanates 80/20, Desmodur T80/20, Desmodur T80

Reviews

There are no reviews yet.