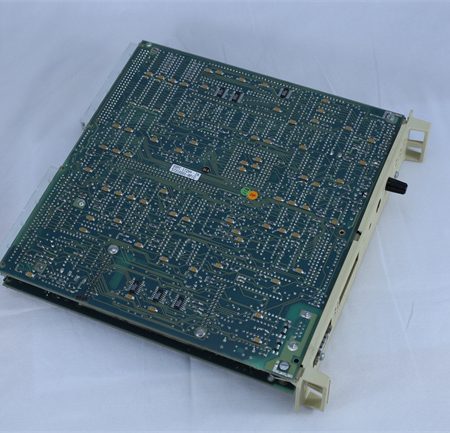

HIMA ELOP II is an advanced industrial automation and safety system provided by HIMA.The following is a detailed introduction to HIMA ELOP II:

1.Overview

HIMA is a leader in industrial automation and safety systems as a partner to the world’s largest process industry companies,including chemical,petrochemical,oil,gas and energy production companies.ELOP II is a system provided by HIMA for industrial automation and process control with a high degree of reliability,safety and flexibility.

HIMA ELOP II

2.Main features

High reliability:HIMA’s products are known for their high reliability,and the ELOP II system is no exception.It can operate stably in harsh industrial environments to ensure the continuity and safety of the production process.

Safety:The ELOP II system integrates safety-related digital inputs and outputs,counters and analog inputs to provide comprehensive safety protection.It complies with international safety standards,such as IEC 61508,IEC 61511 and IEC 62061,etc.,ensuring the safety of the system in various application scenarios.

Flexibility:The ELOP II system can be seamlessly integrated into various industrial systems,providing flexible solutions to adapt to different application scenarios.It supports multiple communication protocols,such as Ethernet,RS485,etc.,to facilitate data exchange with other devices and systems.

Real-time control:The ELOP II system has high-speed processing capabilities and is suitable for real-time control applications.It ensures the accuracy and efficiency of the production process and improves overall production performance.

Advanced programming environment:The ELOP II system provides the application software ELOP II Factory,which enables convenient drag-and-drop programming of modules.This reduces programming difficulty and improves development efficiency.

HIMA ELOP II

3.Application fields

HIMA ELOP II system is widely used in various industrial automation fields,including but not limited to:

Chemical industry:used to monitor chemical reaction processes to ensure production safety and quality.

Petrochemical:Provides critical control functions for petroleum refining and chemical production processes.

Oil and Gas:Plays a key role in the extraction,transmission and processing of oil and gas.

Manufacturing industry:Achieve precise control of automated production lines and improve productivity and product quality.

4.Technical specifications(examples)

Please note that the following technical specifications may vary depending on specific product models and application scenarios.Here are some common examples of technical specifications:

Processor:32-bit ARM Cortex-M3,providing powerful computing power.

Memory capacity:Typically equipped with 256 MB flash memory and 64 MB RAM(some models may vary).

Communication interface:supports Ethernet,RS485 and other communication protocols.

Operating temperature:Operates from-20°C to+70°C(or-20°C to+60°C,depending on model).

Dimensions and weight:Dimensions are approximately 150mm x 100mm x 50mm,weight is approximately 500 grams(depending on model).

5.Summary

HIMA ELOP II is a highly reliable,safe and flexible industrial automation and safety system.It is suitable for various industrial automation fields,ensuring the continuity and safety of the production process and improving overall production performance.When purchasing and using,be sure to refer to the product manual and technical specification sheet to ensure that the product meets your needs and specifications.

The company mainly imports PLC modules,programmable controllers,servo control systems and DCS spare parts,such as:ABB,AB(Rockwell),GE(General Electric),Bentley,Honeywell Er),Emerson.),Motorola,Invensys,Westinghouse,etc.The company has established close cooperative relations with many world-renowned PLC and DCS product maintenance service providers.We can purchase goods directly from abroad and provide equipment and spare parts from different countries and manufacturers.

We supply goods directly from abroad,without intermediaries,reducing the cost of use.

There is really no medium that can make a difference!!

Shenzhen Changxin Automation-sufficient supply,large spot quantity,guaranteed quality,you can buy with confidence and use with peace of mind~!

If you have any defects or needs for imported PLC and DCS spare parts,please contact our team,we will help you find reliable and high-quality products super quickly,while shortening delivery time to ensure that your equipment can operate normally in the right environment.Just in time.

Professionally provide:PLC programmable control system,distributed control system(DCS),safety instrument system(SIS),ESD system,vibration monitoring system,turbo compressor unit control system(CCS)and other PLC modules,various industrial control systems,system modules,CPU,IO module,DO module,AI module,DI module,network communication module,Ethernet module,motion controller,analog input module,analog output module,digital input module,digital output module,module redundancy,power module,relay output unit,relay input unit,processor unit.

Products are widely used in:electricity,petroleum,mine hoisting,ports,heating,gas,water supply,sewage treatment,metallurgy,papermaking,textile,chemical industry,water conservancy and other modern industrial fields!

1.”Power plant DCS monitoring system”

2.”Intelligent flat tempering furnace system manufacturing”

3.”PLC programmable transmission control system”

4.”DCS distributed control system”

5.”Intelligent fire water suppl

Reviews

There are no reviews yet.