Product Description

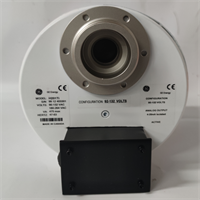

The H201TI GE gas analyzer is designed specifically for gas analysis and monitoring.

feature

100%reactive composite gas sensor

Sensitive to hydrogen(general fault gas)

Carbon dioxide(paper overheating).

LCD display.

As a standard RS-485 connection.

Provide module bus or Heidelberg protocol.

Vacuum resistant gas extraction membrane.

Full system self testing and self diagnosis.

Local recording of data and significant events lasting for a year.

The H201TI GE gas analyzer is the most advanced equipment that can perform accurate and reliable gas analysis.With its advanced technology and user-friendly features,it can provide accurate gas measurement and real-time monitoring in various applications.

HydranTM 201Ti is a small and easy to set up continuous dissolved gas analysis(DGA)monitor in oil.It provides IEEE®The basic information used in standard C57.104 can serve as an important first line of defense for transformers in the fleet,in order to obtain early warning of fault conditions and minimize the risk of unplanned power outages.The composite gas sensor of 201Ti uses fuel cell technology(referred to as Method 3 in the Fixed Instrument Standard)to provide the world-renowned”Hydran gas value”.It has a 100%response to hydrogen gas(general fault gas),and is also sensitive to carbon monoxide(overheated paper),acetylene(arc),and ethylene(overheated oil),thus covering the root causes of all main transformer failures.Due to the installation of monitoring devices on a single valve and the use of dynamic oil sampling,pumps or additional pipelines do not need to be connected to different valves.Due to its simple functionality and easy to understand information,the 201Ti has been one of the preferred displays for many years,and is one of the most widely installed displays among all displays.The Hydran 201Ti monitor adopts the latest Mark IV version,which has undergone comprehensive maintenance and is equipped with a new electronic board and power supply,making it compliant with RoHS standards,solving any outdated issues,and further improving the time validated product.

benefit

Real time single composite fault gas measurement system.

Local and remote alarms are set at predetermined levels or rates of change.

Remote visible gas reading and trend through serial communication

Easy to install on a single valve

There are no moving parts,no pumps,and no additional pipelines required.

No need for on-site calibration.

application area

The H201TI GE gas analysis monitor is widely used in industrial fields such as petrochemicals,steel smelting,and power production.It is used to monitor and control the gas composition and concentration in the production process,improve production efficiency and product quality,and also provide strong technical support for the sustainable development of industrial production.

Reviews

There are no reviews yet.