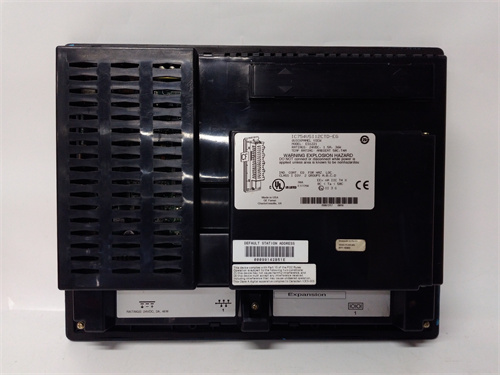

GE IC754VSI12CTD is a medium-sized touch screen human-machine interface(HMI)designed and manufactured by GE Fanuc,mainly used in industrial automation applications.The following is a detailed introduction to the product:

I.Product Features

High-definition display:

Adopts a 12-inch TFT touch screen with a resolution of 800×600,providing clear and delicate picture display.

Powerful functions:

Supports a variety of functions,including data display,trend curves,alarm management,recipe management,etc.,to meet the various needs of industrial automation applications.

Easy to use:

Provides a friendly user interface and intuitive programming software(such as Proficy View-Machine Edition),which is easy to operate and maintain.

Stand-alone operation:

Can be used as a stand-alone device or as part of a network to communicate and exchange data with other devices.

GE IC754VSI12CTD

2.Technical specifications

Display:

Size:12 inches

Type:Color TFT touch screen

Resolution:800×600

Communication interface:

RS232/RS485

Connectable via HMI-CAB-C110 communication cable

Power supply voltage:

12 VDC or 24 VDC

Power consumption:

15 W

Operating temperature:

-20°C to+60°C

Protection level:

IP65

Dimensions:

305 mm×235 mm×68 mm(width×height×depth)

Weight:

Approximately 3 kg(or 10 pounds,depending on the expression)

3.Application scenarios

GE IC754VSI12CTD is suitable for various industrial automation fields,such as manufacturing,chemical,energy,water treatment and other industries.It can be used as an operator terminal,enabling machine operators to simply monitor their applications and monitor,control and adjust them.

GE IC754VSI12CTD

4.Software and operating system

Operating system:

Equipped with Microsoft Windows CE operating system,it is compatible with other Windows versions,making it easy for users to migrate existing program codes.

Programming software:

Proficy View-Machine Edition software can be used for programming and configuration.

V.Other features

Advanced XScale microprocessor:

Combines a high-resolution touch screen operator interface with a variety of I/O options,standard ports and expansion buses for connecting most industrial equipment,and multiple types of memory.

Data retention:

In the event of a sudden power outage,the program is retained in flash memory and user data can be retained in battery-backed SRAM.

The company mainly imports PLC modules,programmable controllers,servo control systems and DCS spare parts,such as:ABB,AB(Rockwell),GE(General Electric),Bentley,Honeywell Er),Emerson.),Motorola,Invensys,Westinghouse,etc.The company has established close cooperative relations with many world-renowned PLC and DCS product maintenance service providers.We can purchase goods directly from abroad and provide equipment and spare parts from different countries and manufacturers.

We supply goods directly from abroad,without intermediaries,reducing the cost of use.

There is really no medium that can make a difference!!

Shenzhen Changxin Automation-sufficient supply,large spot quantity,guaranteed quality,you can buy with confidence and use with peace of mind~!

If you have any defects or needs for imported PLC and DCS spare parts,please contact our team,we will help you find reliable and high-quality products super quickly,while shortening delivery time to ensure that your equipment can operate normally in the right environment.Just in time.

Professionally provide:PLC programmable control system,distributed control system(DCS),safety instrument system(SIS),ESD system,vibration monitoring system,turbo compressor unit control system(CCS)and other PLC modules,various industrial control systems,system modules,CPU,IO module,DO module,AI module,DI module,network communication module,Ethernet module,motion controller,analog input module,analog output module,digital input module,digital output module,module redundancy,power module,relay output unit,relay input unit,processor unit.

Products are widely used in:electricity,petroleum,mine hoisting,ports,heating,gas,water supply,sewage treatment,metallurgy,papermaking,textile,chemical industry,water conservancy and other modern industrial fields!

1.”Power plant DCS monitoring system”

2.”Intelligent flat tempering furnace system manufacturing”

3.”PLC programmable transmission control system”

4.”DCS distributed control system”

5.”Intelligent fire water suppl

Reviews

There are no reviews yet.