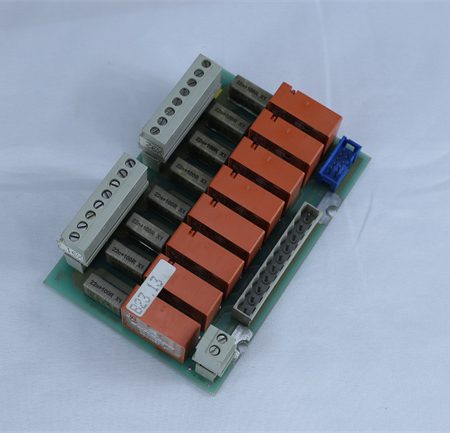

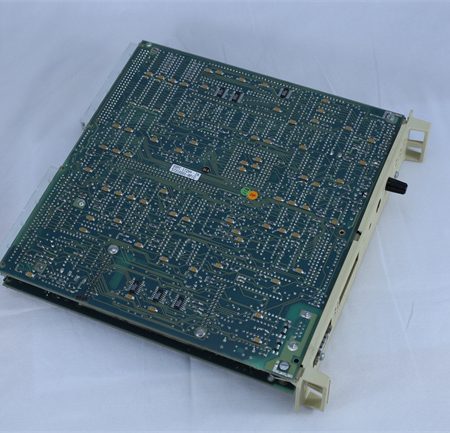

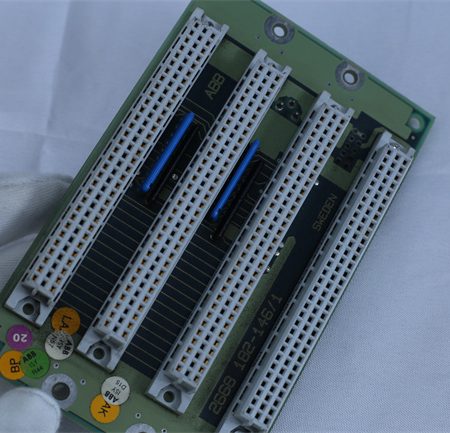

FOXBORO P0400ZG

brand

FOXBORO

Imported or not

no

Processing customization

no

working voltage

220V

output frequency

350kHz

Product Certification

fifty-four thousand and one hundred

series

FOXBORO

Material code

eighty-seven thousand five hundred and forty

Saleable land

nationwide

model

P0400ZG

LiNbO3 10Gb optical modulator NEW(10 lot)

1480 alcatel 1462nm 180mw FBG pump laser 100 lot NEW

tek TLA7AA4/4S/3P 136-Channel LA 2GHz 32Mb/120MHz

81250a 43.2 GHz parBERTe4805b e4861a e4863a e4862a

TEK TLA7016 w/4 X TLA7AA4/8S 235MHz,8MB

AGILENT N4220B P A Probe for PCI express e2960a n4220a

agilent N1737a option 30 OC3/STM1 unit

agilent N1737a ATM test set

When a synchronous motor operates, a three-phase symmetrical current is applied to the three-phase winding of the stator, and a direct current is applied to the excitation winding of the rotor. When three-phase alternating current is applied to the three-phase symmetrical winding of the stator, a rotating magnetic field will be generated in the air gap. When DC current is applied to the rotor excitation winding, a static magnetic field with constant polarity will be generated. If the magnetic pole number of the rotor magnetic field is equal to the magnetic pole number of the stator magnetic field, the rotor magnetic field rotates synchronously with the rotating magnetic field of the stator due to the magnetic pull of the stator magnetic field, that is, the rotor rotates at a speed and direction equivalent to the rotating magnetic field, which is the basic working principle of synchronous motors.

Operation mode

There are three main operating modes of synchronous motors, namely as generators, motors, and compensation machines.

Running as a generator is the main mode of operation for synchronous motors.

Running as an electric motor is another important mode of operation for synchronous motors. The power factor of synchronous motors can be adjusted, and in situations where speed regulation is not required, the application of large synchronous motors can improve operational efficiency. Small synchronous motors are beginning to be widely used in variable frequency speed control systems.

Synchronous motors can also be connected to the power grid as synchronous compensators. At this point, the motor does not carry any mechanical load and sends the required inductive or capacitive reactive power to the power grid by adjusting the excitation current in the rotor, in order to improve the power factor of the power grid or regulate the voltage of the power grid.

Synchronous generators, like other types of rotating motors, consist of two main parts: a fixed stator and a rotatable rotor. It is generally divided into rotary synchronous motors and pivot synchronous motors.

The most commonly used type is a rotary synchronous generator, where the inner circle of the stator core is evenly distributed with stator slots, which are embedded with three-phase symmetrical windings arranged in a regular manner. The stator of this synchronous motor is also known as the armature, and the stator core and winding are also known as the armature core and armature winding.

The rotor iron core is equipped with paired magnetic poles made into a certain shape, and the magnetic poles are wound with excitation windings. When direct current is applied to the magnetic poles, a dispersed magnetic field of polarity will be formed in the air gap of the motor, which is called the excitation magnetic field (also known as the main magnetic field or rotor magnetic field).

The prime mover drives the rotor to rotate (inputting mechanical energy to the motor), and the excitation magnetic field between the polarity phases rotates with the shaft and sequentially cuts the stator windings of each phase (equivalent to the conductor of the winding cutting the excitation magnetic field in the opposite direction).

Reviews

There are no reviews yet.