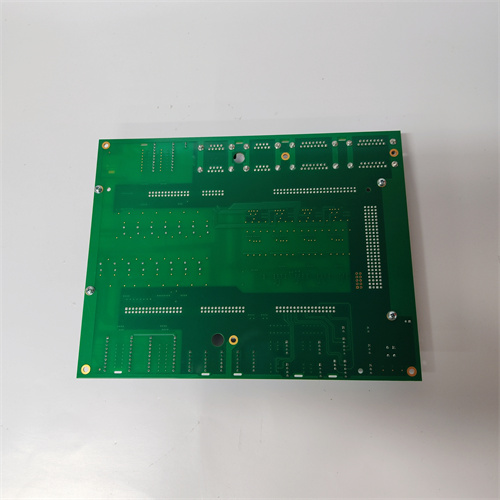

DELTA TAU CLIPPER INTERFACE BOARD 603926-101 is a powerful controller interface board.Here is a detailed introduction to it:

I.Main Features

Integrated advanced technology:

This interface board integrates the world-leading Delta Tau Data Systems motion control technology,giving it excellent performance and reliability in the field of motion control.

Precise multi-axis control:

Designed for precise multi-axis control,it can build a system that can control up to 32 motion axes to meet various complex motion control needs.

DELTA TAU CLIPPER INTERFACE BOARD 603926-101

Programming flexibility:

Allows users to program in C language and reuse existing software assets,which greatly enhances the flexibility and customizability of the system.

Compact design:

The compact design saves space on the machine and control panel,making it possible to achieve high-performance control in a limited space.

Efficient communication:

It has complete communication methods such as high-speed USB,Ethernet or MACRO to ensure real-time and efficient data transmission between the host computer.

Rich industrial protocol support:

In addition to supporting the EtherCAT protocol,it can also provide support for additional industrial protocols such as ProFINET,PROFIUS and Ethernet/IP,which increases the compatibility and application scope of the system.

Stable performance:

The interface board has stable performance and efficient data transmission capabilities,ensuring reliable operation in various application scenarios.

2.Application fields

DELTA TAU CLIPPER INTERFACE BOARD 603926-101 is suitable for a variety of application fields,including but not limited to:

Robot control:

With precise multi-axis control and efficient communication capabilities,this interface board has broad application prospects in the field of robot control.

DELTA TAU CLIPPER INTERFACE BOARD 603926-101

Automated production line:

It can be integrated into the automated production line to achieve precise motion control and data transmission,improve production efficiency and product quality.

Industrial automation:

It is suitable for various industrial automation scenarios,such as food processing,pharmaceuticals,machinery manufacturing,etc.,to provide reliable data support and motion control for industrial automation control systems.

3.Technical specifications and parameters

(Specific technical specifications and parameters may vary depending on product models and manufacturers,the following information is for reference only)

Processor:

It may use a high-performance processor to support complex computing tasks and real-time data processing.

Storage space:Equipped with large-capacity storage space for storing programs and configuration data.I/O interface:Provides a variety of I/O interfaces,such as digital I/O,analog I/O,etc.,to meet different input and output requirements.Communication method:Supports high-speed USB,Ethernet and other communication methods to ensure real-time data transmission between the host computer.Power supply requirements:Specific power supply voltage and current may be required to ensure the normal operation of the interface board.Working environment:Suitable for various industrial environments,such as high temperature,high humidity,dust and other harsh conditions.IV.Installation and debugging When installing and debugging DELTA TAU CLIPPER INTERFACE BOARD 603926-101,be sure to follow the following steps:Read the installation guide:Carefully read the installation guide included with the product to understand the installation steps and precautions of the interface board.Check the hardware connection:During the installation process,ensure that all hardware connections are correct,including power connection,communication connection,etc.Configure software parameters:According to actual needs,configure the software parameters of the interface board,such as motion control parameters,communication parameters,etc.Debug and test:After installation and configuration,debug and test to ensure that the interface board can work properly and meet application requirements.

The company mainly imports PLC modules,programmable controllers,servo control systems and DCS spare parts,such as:ABB,AB(Rockwell),GE(General Electric),Bentley,Honeywell Er),Emerson.),Motorola,Invensys,Westinghouse,etc.The company has established close cooperative relations with many world-renowned PLC and DCS product maintenance service providers.We can purchase goods directly from abroad and provide equipment and spare parts from different countries and manufacturers.

We supply goods directly from abroad,without intermediaries,reducing the cost of use.

There is really no medium that can make a difference!!

Shenzhen Changxin Automation-sufficient supply,large spot quantity,guaranteed quality,you can buy with confidence and use with peace of mind~!

If you have any defects or needs for imported PLC and DCS spare parts,please contact our team,we will help you find reliable and high-quality products super quickly,while shortening delivery time to ensure that your equipment can operate normally in the right environment.Just in time.

Professionally provide:PLC programmable control system,distributed control system(DCS),safety instrument system(SIS),ESD system,vibration monitoring system,turbo compressor unit control system(CCS)and other PLC modules,various industrial control systems,system modules,CPU,IO module,DO module,AI module,DI module,network communication module,Ethernet module,motion controller,analog input module,analog output module,digital input module,digital output module,module redundancy,power module,relay output unit,relay input unit,processor unit.

Products are widely used in:electricity,petroleum,mine hoisting,ports,heating,gas,water supply,sewage treatment,metallurgy,papermaking,textile,chemical industry,water conservancy and other modern industrial fields!

1.”Power plant DCS monitoring system”

2.”Intelligent flat tempering furnace system manufacturing”

3.”PLC programmable transmission control system”

4.”DCS distributed control system”

5.”Intelligent fire water suppl

Reviews

There are no reviews yet.