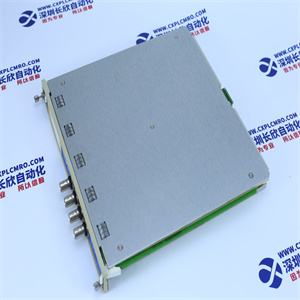

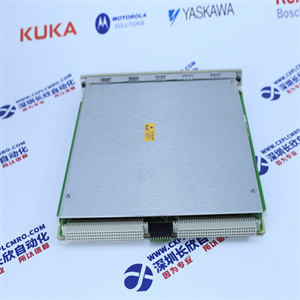

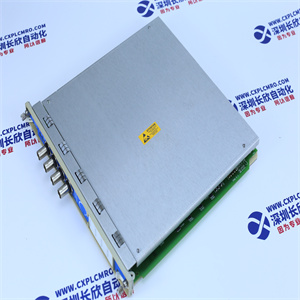

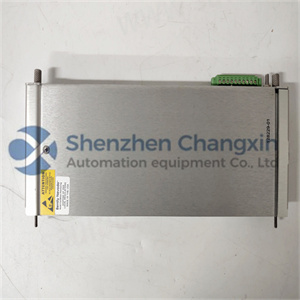

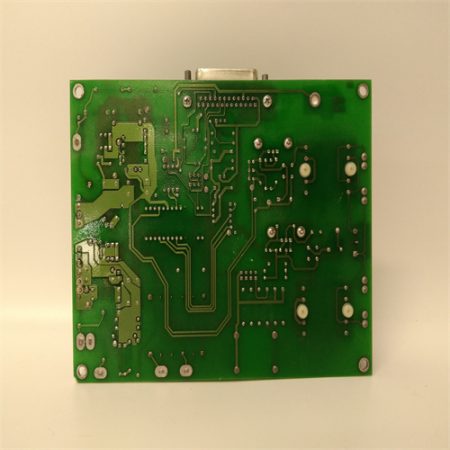

BENTLY 350042M – Product Details, Specifications, Parameters, and Application Areas

Product Details:

The BENTLY 350042M is a high-performance vibration monitoring system from the renowned Bently Nevada Corporation, a leading provider of condition monitoring solutions for rotating machinery. This system is specifically designed to detect, measure, and analyze vibrations in critical rotating equipment to ensure reliable and efficient operation.

Product Specifications:

Hardware Configuration: Details about the system’s hardware components, including sensors, signal conditioners, and any associated electronics.

Measurement Ranges: Specifications of the vibration measurement ranges, including both amplitude and frequency, that the system can accurately detect and analyze.

Accuracy and Resolution: Precise measurements of the system’s ability to accurately measure and resolve vibrations, critical for accurate fault detection and prediction.

Environmental Ratings: Information on the system’s resistance to harsh industrial environments, such as temperature, humidity, and dust, ensuring reliable operation under various conditions.

Product Parameters:

Data Acquisition Rate: The speed at which the system can capture and process vibration data, critical for real-time monitoring and analysis.

Alert and Notification Features: Details about the system’s capabilities to generate alerts and notifications when certain vibration thresholds are exceeded or abnormal conditions are detected.

Integration Options: Information on how the BENTLY 350042M can be integrated with other monitoring systems, control rooms, or enterprise asset management solutions.

Application Areas:

Rotating Machinery Monitoring: The BENTLY 350042M is widely used in monitoring the condition and performance of rotating machinery such as turbines, generators, motors, and pumps in various industries like power generation, oil and gas, and manufacturing.

Predictive Maintenance: By continuously monitoring and analyzing vibrations, the system can predict potential equipment failures, enabling proactive maintenance strategies and minimizing unexpected downtime.

Process Optimization: Real-time vibration data can provide insights into equipment performance, enabling process optimization and improved overall equipment efficiency.

For precise details, specifications, parameters, and recommended application areas specific to the BENTLY 350042M, it is advisable to consult the manufacturer’s official documentation or contact their technical support team.

BENTLY 350042M

BENTLY 350042M

BENTLY 350042M

Reviews

There are no reviews yet.