ABB TB807 is a programmable control system dedicated to industrial automation and process control.It has a wide range of applications in many fields,including production line management,process control,power systems,mechanical equipment,building automation,energy management,traffic control and data center equipment control.For the specific topic of”ABB TB807 PLC CPU”,the following provides a detailed answer:

1.Basic Overview

Model:ABB TB807(may include different specific models or versions,such as 3BSE008538R1,etc.)

Type:Programmable Controller(PLC)CPU

Application scenario:industrial automation and process control

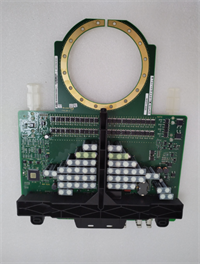

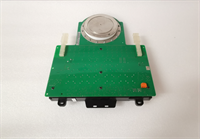

ABB TB807

2.Functional characteristics

High performance:TB807 PLC CPU has high-performance processing capabilities and can handle complex control tasks and real-time data.

Programmability:Through programming software,users can customize control logic and functions according to actual needs.

Extensibility:Supports a variety of I/O modules and expansion units,and can be flexibly configured according to system requirements.

Communication capabilities:It has powerful communication functions,supports a variety of communication protocols and data exchange methods,and is easy to integrate with other devices and systems.

3.Application fields

Industrial automation:used to control and monitor various equipment and processes on industrial production lines to achieve automated production.

Process control:in process industries such as chemical,pharmaceutical,and petroleum,to achieve advanced control of production processes.

Power system:used for monitoring,control and automation of power systems to ensure the stability and reliability of power systems.

Mechanical equipment:control various mechanical equipment such as motors,valves,actuators,etc.to achieve precise control of equipment.

ABB TB807

4.Technical specifications(taking 3BSE008538R1 as an example)

(Note:the specific technical specifications may vary depending on the model and version,the following information is for reference only)

Processor performance:high-performance CPU to meet the needs of complex control tasks.

Memory:sufficient memory space for storing programs and data.

I/O points:supports a variety of I/O modules,which can be configured according to needs.

Communication interface:a variety of communication interfaces,supporting different communication protocols.

The company mainly imports PLC modules,programmable controllers,servo control systems and DCS spare parts,such as:ABB,AB(Rockwell),GE(General Electric),Bentley,Honeywell Er),Emerson.),Motorola,Invensys,Westinghouse,etc.The company has established close cooperative relations with many world-renowned PLC and DCS product maintenance service providers.We can purchase goods directly from abroad and provide equipment and spare parts from different countries and manufacturers.

We supply goods directly from abroad,without intermediaries,reducing the cost of use.

There is really no medium that can make a difference!!

Shenzhen Changxin Automation-sufficient supply,large spot quantity,guaranteed quality,you can buy with confidence and use with peace of mind~!

If you have any defects or needs for imported PLC and DCS spare parts,please contact our team,we will help you find reliable and high-quality products super quickly,while shortening delivery time to ensure that your equipment can operate normally in the right environment.Just in time.

Professionally provide:PLC programmable control system,distributed control system(DCS),safety instrument system(SIS),ESD system,vibration monitoring system,turbo compressor unit control system(CCS)and other PLC modules,various industrial control systems,system modules,CPU,IO module,DO module,AI module,DI module,network communication module,Ethernet module,motion controller,analog input module,analog output module,digital input module,digital output module,module redundancy,power module,relay output unit,relay input unit,processor unit.

Products are widely used in:electricity,petroleum,mine hoisting,ports,heating,gas,water supply,sewage treatment,metallurgy,papermaking,textile,chemical industry,water conservancy and other modern industrial fields!

1.”Power plant DCS monitoring system”

2.”Intelligent flat tempering furnace system manufacturing”

3.”PLC programmable transmission control system”

4.”DCS distributed control system”

5.”Intelligent fire water suppl

Reviews

There are no reviews yet.