ABB CP800 is a high-performance,high-reliability communication control processor produced by ABB and widely used in the field of industrial automation.The following is a detailed introduction to ABB CP800:

I.Product Overview

The ABB CP800 controller is designed to meet the high requirements for data processing and communication in the field of industrial automation.It uses advanced microprocessor and control technology to ensure fast and accurate data processing capabilities,which is essential for real-time control systems.

II.Main functions and features

Multiple communication interfaces:

ABB CP800 supports a variety of communication interfaces including Ethernet,which makes it compatible with different devices and network systems,providing flexible integration solutions for industrial automation.

High performance:

The processor is based on a 256 MHz,32-bit Freescale Coldfire processor and can handle various control tasks quickly and accurately.

It can perform complex mathematical operations and data processing to meet the needs of various control systems.

High reliability:

As an industrial-grade product,ABB CP800 is designed with stability and durability in mind and can maintain good performance in harsh industrial environments.

It adopts redundant design,including CPU,power supply,internal bus,I/O network,communication port,etc.,to ensure the highest availability and reliability of the system.

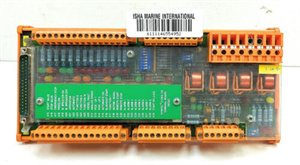

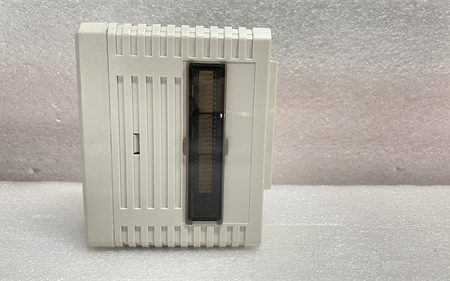

ABB CP800

Modular design:

The CP800 communication control processor adopts modular design,which is convenient for users to configure and expand according to actual needs.

Powerful control capability:

It supports SD series I/O,Harmony rack I/O and S800 I/O subsystems,and can perform closed-loop control of more than 5,000 I/Os in less than 250 milliseconds.

At the same time,it also supports 30,000 function blocks,has flexible online configuration capabilities,and supports up to 8 segmented tasks,and the execution cycle time of each segment can be reduced to 1 millisecond.

Ease of use:

ABB CP800 provides a friendly user interface and rich programming software(such as S+engineering tools)to facilitate user operation and maintenance.

It also adopts DIN rail form factor and standard 24 VDC power input,which is simple and flexible to install.

ABB CP800

3.Application fields

ABB CP800 communication control processor is commonly used in the field of industrial automation to connect and coordinate various components in industrial control systems,including PLC(programmable logic controller),sensors,actuators,etc.Specifically,it can be applied to the following fields:

Mechanical manufacturing:used to control and monitor various mechanical equipment to ensure their accuracy and efficiency in the production process.

Logistics and transportation:control transportation systems such as automated warehousing systems,conveyor belts and automatic guided vehicles.

Energy production:control equipment related to energy production,such as wind turbines and solar tracking systems.

Scientific research:used to control experimental equipment and scientific instruments in laboratories and research centers.

Aerospace:used to control motion control of motion systems such as aircraft and satellites.

Automobile manufacturing:control robots and automation equipment on production lines to improve the efficiency of automobile manufacturing.

4.Summary

ABB CP800 is a powerful,easy-to-use and maintain communication control processor that can meet the requirements of high performance,high reliability and flexibility in the field of industrial automation.Through its rich communication interfaces and powerful control capabilities,ABB CP800 provides a reliable control and communication solution for industrial automation,helping to improve production efficiency and system reliability.

The company mainly imports PLC modules,programmable controllers,servo control systems and DCS spare parts,such as:ABB,AB(Rockwell),GE(General Electric),Bentley,Honeywell Er),Emerson.),Motorola,Invensys,Westinghouse,etc.The company has established close cooperative relations with many world-renowned PLC and DCS product maintenance service providers.We can purchase goods directly from abroad and provide equipment and spare parts from different countries and manufacturers.

We supply goods directly from abroad,without intermediaries,reducing the cost of use.

There is really no medium that can make a difference!!

Shenzhen Changxin Automation-sufficient supply,large spot quantity,guaranteed quality,you can buy with confidence and use with peace of mind~!

If you have any defects or needs for imported PLC and DCS spare parts,please contact our team,we will help you find reliable and high-quality products super quickly,while shortening delivery time to ensure that your equipment can operate normally in the right environment.Just in time.

Professionally provide:PLC programmable control system,distributed control system(DCS),safety instrument system(SIS),ESD system,vibration monitoring system,turbo compressor unit control system(CCS)and other PLC modules,various industrial control systems,system modules,CPU,IO module,DO module,AI module,DI module,network communication module,Ethernet module,motion controller,analog input module,analog output module,digital input module,digital output module,module redundancy,power module,relay output unit,relay input unit,processor unit.

Products are widely used in:electricity,petroleum,mine hoisting,ports,heating,gas,water supply,sewage treatment,metallurgy,papermaking,textile,chemical industry,water conservancy and other modern industrial fields!

1.”Power plant DCS monitoring system”

2.”Intelligent flat tempering furnace system manufacturing”

3.”PLC programmable transmission control system”

4.”DCS distributed control system”

5.”Intelligent fire water suppl

Reviews

There are no reviews yet.