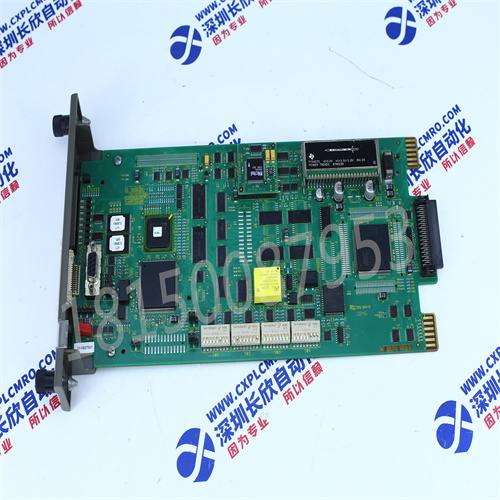

ABB BRC300

The ABB BRC300 is a digital regulator for controlling process variables in industrial applications. It is designed to regulate temperature, pressure, flow, and other variables in a wide range of processes. The BRC300 has a user-friendly interface with a large, easy-to-read display and intuitive menu-driven navigation.

Some of the key features of the BRC300 include:

- Multiple control modes: The BRC300 supports several control modes, including PID control, ON/OFF control, and manual control.

- Programmable set points: The operator can set and adjust the desired set points for the process variable.

- Alarm functions: The BRC300 has built-in alarm functions to alert the operator in case of a process variable going out of range or other critical conditions.

- Data logging: The BRC300 can log process data for analysis and troubleshooting purposes.

- Communication capabilities: The BRC300 supports various communication protocols, including Modbus, for easy integration with other systems.

Agilent 44476A Microwave switch with 30 Days Warranty

IDEC IZUMI CORP.CC PENDANT HG2R-MK1076-2 HG2 SERIES

2 GB SDRAM PC133 ECC REG.3.3V ATP AMR64V72J4S8GAS

Bailey infi90 Infi 90 IMASI03 with Warranty&Free PP

FUJI FRENIC 5000 P3 009P3-4Z 500CC 9kva FREE PARTS SUPP

SCHINDLER ELIVATOR CONTROLLER ID.NR.590654 pc based isa

JDS Uniphase Helium-Neon Lasers PSU 101T-1250-4-TTL-2

BEAM REMOTE SATELLITE TERMINAL RST100 DISPLAY UNIT

The main features and parameters of the ABB BRC300 include:

- Modularity: The BRC300 can be configured with different modules to meet specific application requirements. It supports various types of I/O modules, communication modules, and function modules.

- Scalability: The controller is highly scalable, allowing for expansion and integration with other control systems as the process requirements grow.

- Communication: The BRC300 supports standard communication protocols like Modbus, Profibus, and Ethernet. It can connect with various field devices, HMI (Human-Machine Interface), and SCADA (Supervisory Control and Data Acquisition) systems.

- Programming: The controller uses the IEC 61131-3 programming languages, which include ladder diagram (LD), function block diagram (FBD), structured text (ST), and sequential function chart (SFC). This allows for flexible and efficient programming of control logic.

- Redundancy: The BRC300 offers high availability through its redundant architecture. It supports redundant controllers, power supplies, and communication networks, ensuring the continuity of process control even in case of failures.

- Diagnostics and Maintenance: The controller provides extensive diagnostic functions to monitor the status of hardware and software components. It also supports remote access for troubleshooting and maintenance purposes.

- Integrated Control Algorithms: The BRC300 includes advanced control algorithms, such as PID (Proportional-Integral-Derivative) control, fuzzy logic, and model predictive control. These algorithms help optimize the performance of the controlled process.

- HMI Integration: The controller can be seamlessly integrated with ABB’s process visualization and control system, System 800xA. This allows for a unified HMI experience and efficient plant-wide control.

- Compliance: The BRC300 complies with international standards and regulations, ensuring reliability, safety, and sustainability in industrial processes.

Reviews

There are no reviews yet.