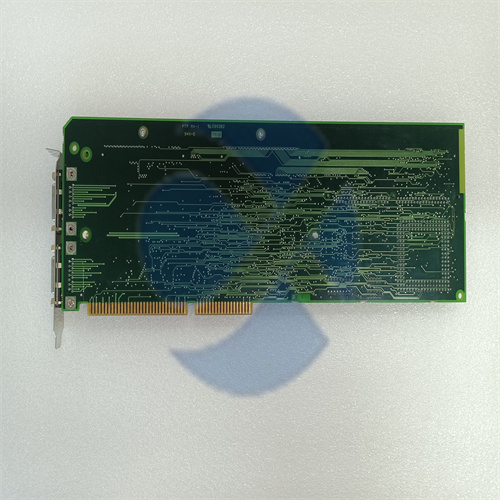

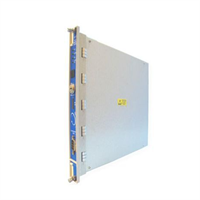

Product Description

24765-02-01 BENTLY NEVADA Shell Expansion Sensor Assembly(DC)is used to measure the expansion or contraction of equipment shells.

feature

DC power supply

High precision measurement

Durable and stable

24765-02-01 BENTLY NEVADA Housing Expansion Sensor Assembly(DC)is a sensor assembly designed specifically for measuring equipment housing expansion or contraction.It can provide accurate readings so that you can closely monitor the status of the device and make corresponding adjustments.

24765-02-01 BENTLY NEVADA Housing Expansion Sensor Assembly(DC)BENTLY NEVADA Housing Expansion Sensor Assembly uses advanced measurement technology and high-quality materials to provide reliable performance in various working environments.

24765-02-01 BENTLY NEVADA casing expansion(sometimes referred to as casing expansion)is the thermal growth caused by casing expansion during machine startup and online operation.The shell expansion sensor system is usually installed on the foundation connected to the turbine casing at the other end of the foundation,and provides information on the growth of the machine casing relative to the foundation.Case expansion is a parameter that you should use a dual sensor arrangement to measure.This arrangement provides information about the position of the sliding feet on the machine casing.If one foot is obstructed or stuck,it may deform the chassis and damage the machine.The dual housing expansion sensor configuration,along with the 3300 or 3500 monitor,provides an alarm for this situation.The high-temperature dual shell expansion sensor configuration is only compatible with the 3500/45 position monitor.The shell expansion measurement also allows you to determine whether the machine conditions exceed the expected temperature growth differences.This is mainly a startup parameter that determines whether the machine casing and rotor are thermally growing at almost the same speed.Different heat growth rates can cause friction between the rotating and stationary parts of the machine.The casing expansion sensor assembly consists of a linear variable differential transformer(LVDT)installed in a weather proof protective casing.The working principle of the casing expansion sensor system uses LVDT to measure the thermal growth of the machine casing.A rod on the LVDT is connected to the machine.As the machine casing grows,the rod moves within the LVDT and changes the signal in the LVDT.The converter electronically adjusts the signal and outputs it to the monitor for display and alarm.The design of the high-temperature shell expansion transmitter meets the requirements of TYPE 4.

An important position measurement in the turbine monitoring instrument(TSI)for measuring thermal condition growth in large steam turbines is condition expansion.Shell expansion(sometimes referred to as shell expansion)is the thermal expansion of the shell during machine startup and online operation.The casing expansion transducer system is usually installed on the foundation connected to the turbine casing at the other end of the foundation,and provides information about the casing growth relative to the foundation.Case expansion is a parameter that you should use a dual sensor arrangement to measure.This arrangement provides information about the position of the sliding feet on the machine casing.A foot that is obstructed or stuck may deform the chassis and damage the machine.The dual housing expansion sensor configuration,combined with a 3300 or 3500 monitor,can provide an alarm for this situation.The high-temperature dual shell expansion sensor configuration is only compatible with the 3500/45 position monitor.The shell expansion measurement also allows you to determine whether the machine conditions exceed the expected temperature growth difference.This is mainly a startup parameter that determines whether the casing and rotor are thermally growing at almost the same speed.Different heat growth rates can cause friction between the rotating and stationary parts of the machine.The shell expansion sensor assembly consists of a linear variable differential transformer(LVDT)installed in a temperature protected housing.

application area

24765-02-01 BENTLY NEVADA shell expansion sensor components(DC)are widely used in various industrial fields,such as automotive manufacturing,aerospace,petrochemical,etc.

Reviews

There are no reviews yet.