NI sbRIO-9607 – Rugged, Fanless sbRIO Module with Gigabit Ethernet, USB, and SD Card for Standalone Operation

Description

The NI sbRIO-9607 is a high-performance single-board RIO (reconfigurable I/O) controller from National Instruments (now part of Emerson via the acquisition of NI’s embedded portfolio). Designed for embedded control, monitoring, and edge intelligence applications, it integrates a dual-core ARM Cortex-A9 real-time processor running NI Linux Real-Time OS with a powerful Xilinx Kintex-7 160T FPGA—all on a compact 100 × 100 mm PCB. With no moving parts, industrial I/O, and support for standalone operation, the sbRIO-9607 is ideal for robotics, power converters, structural health monitoring, and custom test systems where low latency, determinism, and onboard processing are critical.

Application Scenarios

At a European wind turbine manufacturer, engineers needed to implement real-time blade pitch control with <10 µs response to gust loads—too fast for standard PLCs. They selected the NI sbRIO-9607. using its Kintex-7 FPGA to process encoder feedback and execute PID loops at 100 kHz, while the real-time processor handled communication with the SCADA system via Modbus TCP. The entire controller fit inside the nacelle’s tight electronics bay, operating reliably at -30°C during Arctic winters. Over two years of field deployment across 48 turbines, the sbRIO-9607 achieved 99.99% uptime—proving its value as a high-integrity edge compute node in renewable energy.

Technical Principles and Innovative Values

Innovation Point 1: True Hardware-Software Co-Design

The sbRIO-9607 enables developers to split tasks optimally: time-critical loops (e.g., motor commutation, PWM generation) run in the FPGA, while higher-level tasks (data logging, network protocols) execute on the real-time CPU—maximizing performance without OS jitter.

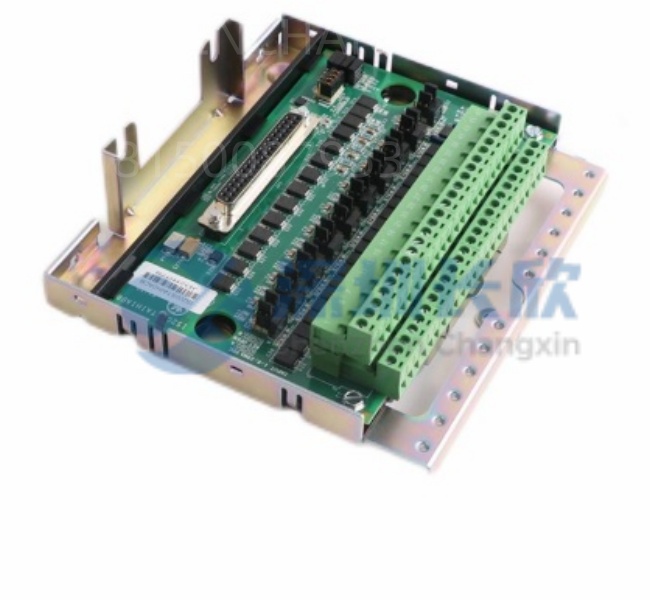

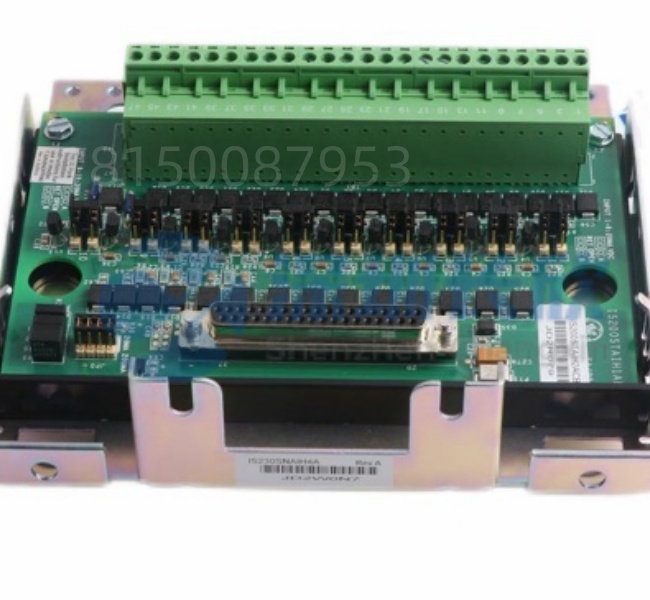

Innovation Point 2: Carrier Board Flexibility

Unlike fixed-I/O controllers, the sbRIO-9607 uses two high-density connectors to interface with custom carrier boards—allowing tailored analog, digital, or communication I/O for aerospace, medical, or energy applications.

Innovation Point 3: Deterministic Gigabit Ethernet to FPGA

One Ethernet port connects directly to the FPGA fabric, enabling ultra-low-latency UDP or custom protocol communication—ideal for synchronized multi-axis motion or distributed sensor networks.

Innovation Point 4: Standalone Operation with Local Storage

With eMMC and microSD support, the sbRIO-9607 can boot and run independently—perfect for remote monitoring stations where PC connectivity is unavailable.

Application Cases and Industry Value

In a U.S. electric vehicle startup, the sbRIO-9607 was used as the core of a battery cycler test system. The FPGA generated precise current waveforms at 50 kHz, while the real-time processor logged voltage/temperature data to SD card and uploaded summaries via cellular modem. The system reduced test cycle time by 40% compared to legacy DAQ solutions.

In Japan, a seismic research institute deployed sbRIO-9607 units across 12 fault-line sites. Each unit sampled geophone arrays at 10 kHz, performed real-time FFT in the FPGA, and triggered local alerts upon detecting P-waves—demonstrating sub-second earthquake early warning capability.

Related Product Combination Solutions

NI 9607 Carrier Board (e.g., custom or third-party): Provides analog inputs, digital I/O, or CAN bus interfaces.

LabVIEW 2023 SP1 (or later): Primary development environment for programming real-time and FPGA logic.

NI VeriStand: For deploying real-time simulation and HIL (Hardware-in-the-Loop) test systems on sbRIO-9607.

Xilinx Vivado (optional): For advanced FPGA users requiring HDL (VHDL/Verilog) integration.

NI Linux Real-Time SDK: Enables C/C++ application development outside LabVIEW.

sbRIO-9606: Pin-compatible predecessor with Artix-7 FPGA (lower performance, lower cost).

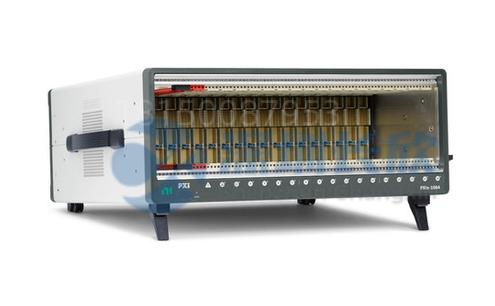

CompactRIO Chassis (e.g., cRIO-904x): Alternative if modular I/O is preferred over single-board design.

Installation, Maintenance, and Full-Cycle Support

The NI sbRIO-9607 is typically mounted on a custom carrier board inside an IP-rated enclosure. Power is applied via screw terminals or pluggable connector, and initial setup is done over Ethernet using NI MAX (Measurement & Automation Explorer). Firmware updates and application deployment are managed through LabVIEW or WebDAV.

For maintenance, the board supports remote reboot, file system access, and FPGA bitfile reloading—minimizing site visits. Its fanless, solid-state design ensures long life in dusty or vibrating environments.

Every NI sbRIO-9607 we supply is tested for:

Power-on self-test (POST)

Ethernet link integrity

FPGA configuration success

Real-time OS boot stability

We provide a one-year warranty, full documentation (including pinout and thermal specs), and engineering support for carrier board integration or migration from legacy NI platforms.

⚠️ Note: As of 2023. National Instruments’ embedded products (including sbRIO) are transitioning under Emerson. Ensure compatibility with future software support timelines.

Contact us for a complete edge control solution—whether you’re building a custom test stand, deploying distributed sensors, or modernizing legacy automation with FPGA-powered intelligence.