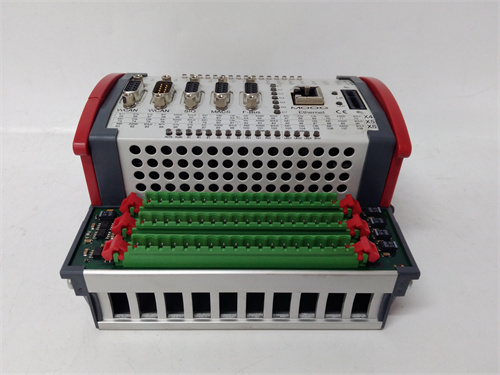

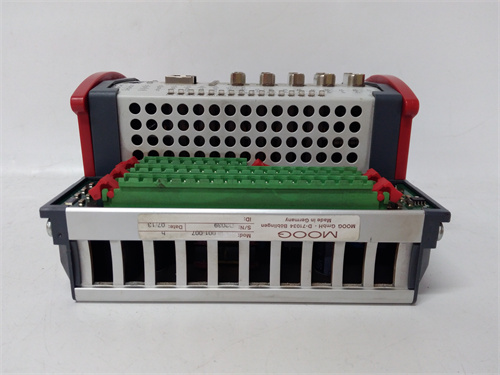

D136-001-007 is a controller module or servo drive produced by MOOG.The following is a detailed introduction to the product:

1.Product Overview

D136-001-007 is a high-performance controller module or servo drive produced by MOOG.It integrates a variety of advanced functions and technologies and can be widely used in industrial automation,CNC machine tools,printing and packaging,food and beverage production,medical equipment,aerospace,and laboratory instruments.

2.Product Features

Support single-axis and multi-axis linkage control:

D136-001-007 supports single-axis and multi-axis linkage control,which can meet the needs of various complex motion control.

Support electronic cam,variable electronic gear ratio,motion superposition,virtual spindle,linear/circular/helical interpolation functions,which improves the flexibility and accuracy of the system.

MOOG D136-001-007

Built-in upper control:

Built-in upper control function,supports ladder logic programming,and simplifies the system design and debugging process.

Each axis contains 8 digital inputs,8 digital outputs,and 2 analog inputs,which is convenient for connection and communication with external devices.

Multiple communication interfaces and protocols:

Supports communication interfaces such as RS-422 and RS-485,which is convenient for connecting with various control systems.

Supports multiple communication protocols such as MODBUS,which improves the compatibility and scalability of the system.

MOOG D136-001-007

Supports multiple motor types:

Supports multiple motor types such as servo motors,DC brushless motors,direct drive motors,linear motors,etc.,to meet the needs of different application scenarios.

Multiple feedback methods:

Supports multiple feedback methods such as incremental,absolute,resolver,Sin/cos analog,Hall,magnetic grating/grating feedback,etc.,which improves the accuracy and stability of the system.

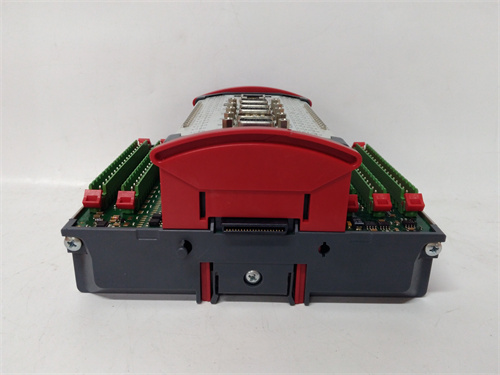

Flexible installation method:

Supports multiple installation methods such as independent installation,PCB board installation,and motor integrated installation,which is convenient for users to choose according to actual needs.

Efficiency and real-time performance:

Adopts high-performance processors and algorithms,which can quickly and accurately complete various control tasks.

Can receive and process various input signals in real time,and can quickly output control signals to achieve real-time control and adjustment.

Reliability and stability:

Adopts stable and reliable hardware and software design,with high stability and reliability.

The optimized main circuit hardware design enhances the protection function in the case of unstable power grid and sudden load increase,and reduces the risk of failure.

Ease of use and maintainability:

It has a simple and easy-to-use user interface and operation mode,which is convenient for users to set parameters,control operations and monitor management.

It adopts an easy-to-maintain design,which is convenient for users to perform daily maintenance and maintenance,and prolongs the service life of the product.

III.Application fields

D136-001-007 can be widely used in the following fields:

Industrial automation:used to control various motor drive equipment on the production line,such as conveyor belts,robotic arms,machine tools,etc.

CNC machine tools:used to achieve high-precision control of tools and workbenches to ensure accurate processing of workpieces.

Printing and packaging:used to control equipment such as printing rollers and cutting machines to improve production efficiency and printing quality.

Food and beverage production:used to control equipment such as mixers,filling machines,packaging machines,etc.to ensure the stable operation of the production line.

Medical equipment:used to accurately control the movement of medical devices,such as surgical robots,CT scanners,etc.

Aerospace:used to control the rudder of aircraft,the guidance system of missiles,etc.

Laboratory instruments:used to control experimental instruments to ensure the accuracy and repeatability of experiments.

.jpg)