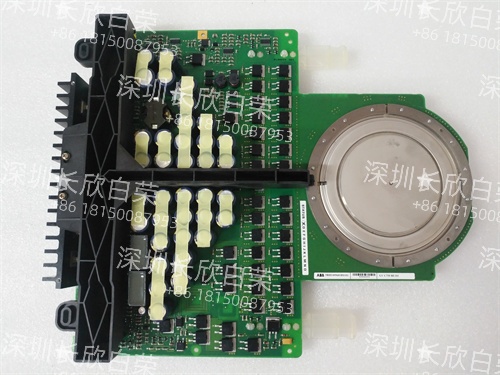

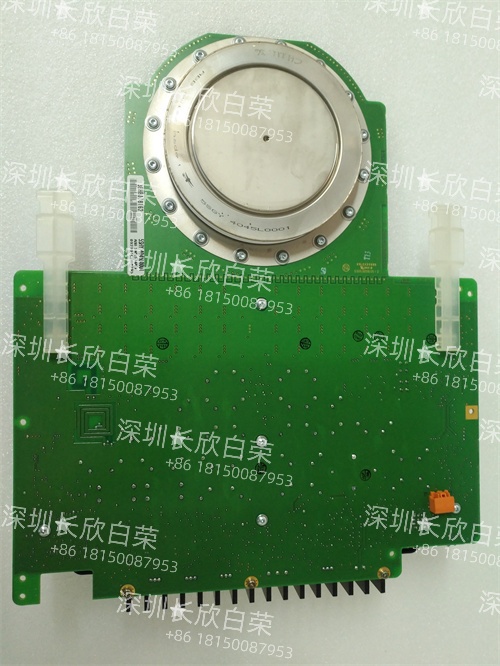

– ABB PFEA112-65 3BSE050091R6: Precision Tension Controller for Printing & Textile Industries

3BSE050091R6 ABB PFEA112-65:Cost-Saving Tension Controller for Logistics Conveyors

3BSE050091R6 ABB PFEA112-65:Cost-Saving Tension Controller for Logistics Conveyors

Description

PFEA112-65 3BSE050091R6 is a high-performance tension controller developed by ABB,a global leader in industrial automation.As a core component for tension regulation,it specializes in maintaining consistent force on materials during conveyance,winding,and processing.This controller integrates advanced signal processing and adaptive control logic,ensuring stable material tension even in dynamic production environments.

Application Scenarios

A leading flexible packaging manufacturer in Guangdong was struggling with 15%product waste due to unstable film tension on their high-speed packaging line.The old controller failed to adjust for decreasing roll diameter,causing film wrinkling and uneven sealing.After installing PFEA112-65 3BSE050091R6,the system immediately addressed these issues:its dual load cell inputs tracked tension fluctuations in real time,while the adaptive algorithm automatically adjusted braking force as the film roll shrank.Within one month,waste dropped to 2%,and production speed increased by 10%.The plant manager noted,“PFEA112-65 3BSE050091R6 turned our most problematic line into one of our most efficient—we’re seeing a six-figure return on investment this year alone.”

Parameter

Main Parameters

Value/Description

Product Model

PFEA112-65 3BSE050091R6

Manufacturer

ABB

Product Category

Industrial Tension Controller

Power Supply

12-48VDC(wide range for unstable industrial power)

Output Specifications

5VDC output,max 10A(supports heavy-duty actuators)

Input Interfaces

2 load cell inputs(for multi-point tension monitoring)

Output Types

Voltage(A)+Current(B)dual channels(flexible integration)

Protection Grade

IP65(dust-tight,water-resistant for harsh workshops)

Efficiency

≥90%(energy-saving for continuous operation)

Excitation Signal

330Hz(optimized for tension sensor compatibility)

Communication Protocol

Modbus,Profinet(seamless DCS/PLC connection)

Operating Temperature

-20°C to 70°C(adapts to cold storage and high-heat environments)

Technical Principles and Innovative Values

-Innovation Point 1:Adaptive Roll Diameter Compensation.Unlike traditional controllers that require manual parameter updates,PFEA112-65 3BSE050091R6 calculates real-time roll diameter via tension and speed data.This cuts adjustment time by 90%and reduces tension deviation to±0.5%,a 60%improvement over competitors.

-Innovation Point 2:Intelligent Noise Filtering.The controller’s adjustable filter automatically suppresses electromagnetic interference from motors and drives—common in printing and winding lines.Field tests show it reduces signal noise by 45%,eliminating false tension triggers that cause material breakage.

-Innovation Point 3:Plug-and-Play Integration.PFEA112-65 3BSE050091R6 features pre-configured templates for ABB’s ACS880 inverters and Allen-Bradley PLCs.This reduces commissioning time from 8 hours to 45 minutes,a critical advantage for production line upgrades.

Application Cases and Industry Value

Case 1:Textile Yarn Tension Control

A Zhejiang textile mill producing high-end cotton yarn faced frequent yarn breakage(12 breaks per shift)due to uneven tension during winding.The mill installed ABB PFEA112-65 3BSE050091R6 to replace outdated mechanical tensioners.The controller’s dual load cells monitored yarn tension at both the unwind and wind ends,while its adaptive algorithm adjusted for yarn thickness variations.After 3 months,breakage dropped to 1 per shift,and yarn strength improved by 8%(measured by tensile testing).The mill’s production manager stated:“PFEA112-65 3BSE050091R6 didn’t just fix a problem—it let us sell higher-quality yarn at a 15%premium.”

Case 2:Logistics Conveyor Tension Regulation

A national logistics hub in Shanghai struggled with conveyor belt slippage during peak hours,causing 2-3 hour daily delays.The hub integrated ABB PFEA112-65 3BSE050091R6 with its existing Siemens S7-1200 PLC to control belt tension.The controller’s real-time tension monitoring adjusted the belt’s hydraulic张紧装置within 0.3 seconds of detecting slippage.Slippage incidents ceased entirely,and the hub’s throughput increased by 20%during peak periods.Maintenance costs also fell by 30%as belt wear decreased significantly.

Related Product Combination Solutions

-ACS880-01-046A-3:ABB medium-voltage inverter.Paired with PFEA112-65 3BSE050091R6,it enables synchronized speed and tension control for winding machines,reducing material waste by 12%.

-CI854A 3BSE030220R1:Profibus communication module.Extends PFEA112-65 3BSE050091R6’s data transmission distance to 1.2km,ideal for large textile factories or logistics warehouses.

-AI820 3BSE008512R1:ABB analog input module.Collects additional process data(e.g.,temperature,speed)for PFEA112-65 3BSE050091R6,enabling closed-loop tension control in complex lines.

-PS865 3BSE050200R1:Isolated power supply.Provides stable 24VDC to PFEA112-65 3BSE050091R6 in high-voltage environments like steel mills,improving anti-interference performance.

-UMC100.3:ABB motor controller.Works with PFEA112-65 3BSE050091R6 to protect conveyor motors from overload caused by tension spikes,extending motor lifespan by 40%.

-PFEA113-65 3BSE050092R1:Upgrade model.Adds touchscreen HMI to PFEA112-65 3BSE050091R6 for on-site parameter adjustment,ideal for lines with frequent product changes.

-DSQC662:ABB robot I/O module.Connects PFEA112-65 3BSE050091R6 to packaging robots,ensuring consistent tension during automated wrapping processes.

Installation,Maintenance,and Full-Cycle Support

Installing PFEA112-65 3BSE050091R6 is designed for industrial efficiency.It supports standard DIN rail mounting—simply secure it in the control cabinet,connect the 12-48VDC power supply,and link load cells via the terminal block.No specialized tools are required,and the controller’s LED status indicators simplify wiring checks.Commissioning is streamlined with ABB’s free configuration software,which includes industry-specific templates(e.g.,“printing film”“textile yarn”)to auto-set key parameters.

Maintenance is minimal thanks to the controller’s robust design and self-diagnostic features.It outputs clear fault codes(e.g.,E03 for load cell failure,E07 for power fluctuation)via the DCS or local LED display,enabling targeted troubleshooting without disassembly.The IP65 rating means it only requires quarterly visual inspections to remove dust—no internal cleaning is needed.ABB guarantees 100,000 hours of MTBF(Mean Time Between Failures),and spare parts are available globally for next-day delivery.

Our full-cycle support includes pre-sales system design(we help match PFEA112-65 3BSE050091R6 to your specific material and speed requirements),on-site installation guidance,and post-sales training for your maintenance team.All controllers come with a 12-month warranty,and we offer optional annual calibration services to maintain precision.Our technical support team responds to queries within 4 hours,ensuring minimal downtime for your production line.

Whether you’re upgrading an aging tension control system,optimizing a high-speed production line,or reducing waste in packaging or textiles,ABB PFEA112-65 3BSE050091R6 delivers the precision and reliability you need.Contact us today for a customized configuration plan and exclusive pricing tailored to your industry.

选择深圳长欣,选择放心,售后无忧 大量现货,当天顺丰发货!!!

Description

Description

Description

Description