Honeywell 05701-A-0302 Technical Overview: Core Component of System 57 Gas Detection

Description

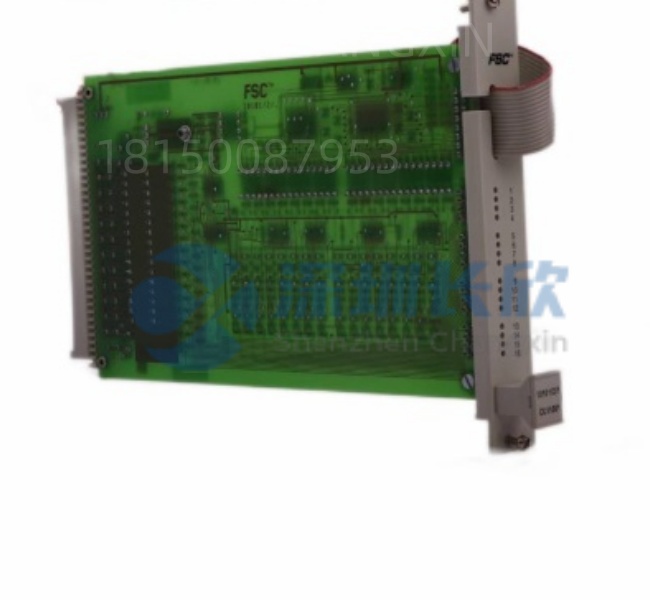

The Honeywell 05701-A-0302 is a Single Channel Control Card manufactured by Honeywell, designed as a key component within the Honeywell Zellweger Analytics System 57 . This module provides precise control, display, and alarm management for a connected gas detector, specifically engineered to monitor combustible gases using catalytic bead sensors in various industrial settings .

Application Scenarios

In an oil and gas refinery, protecting personnel and assets from the dangers of combustible gas leaks is paramount. Imagine a scenario where a leak occurs near a compressor station. A catalytic bead sensor detects the rising gas concentration and sends a signal to the Honeywell 05701-A-0302 Single Channel Control Card . The card’s processor immediately compares the signal to predefined alarm thresholds (A1. A2. A3). Within moments, it triggers both a visual alert on its front-panel LED and an audible alarm through the system, while also activating a relay to initiate safety protocols like shutting down equipment or starting ventilation fans . This rapid, reliable response, managed locally by the 05701-A-0302. is critical for preventing incidents and ensuring operational safety in hazardous areas .

Parameter

Technical Principles and Innovative Values

Innovation Point 1: Integrated Multi-Function Display for Clear Situational Awareness. The Honeywell 05701-A-0302 incorporates a sophisticated four-part liquid crystal display (LCD) system . This integrates an analog bar-graph for quick visual level assessment, a precise four-digit numerical readout, a text area for system messages, and icon-based status indicators. This multi-faceted approach provides operators with immediate, unambiguous information on gas levels and system status, enhancing decision-making during critical events .

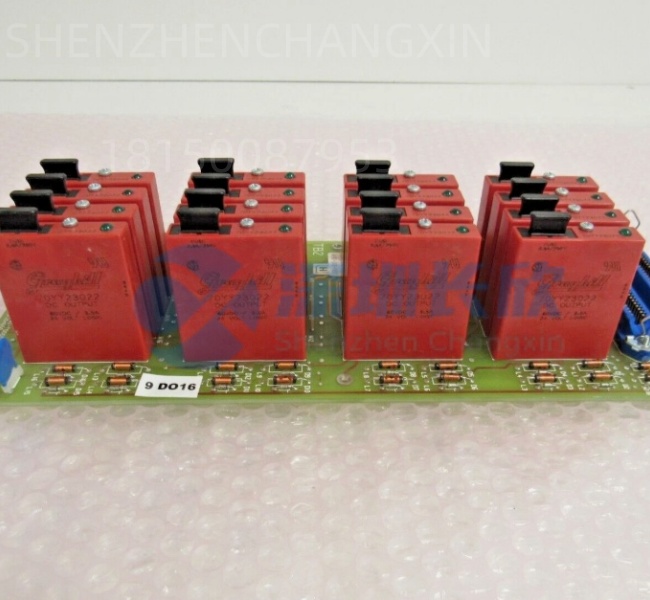

Innovation Point 2: Comprehensive Alarm Management and Self-Diagnostic Capabilities. The card is designed for high reliability through its robust alarm management system, featuring three distinct gas alarm levels and dedicated fault indicators . More importantly, it performs continuous self-verification, constantly checking the health of its internal software, hardware, and the connected sensor . This proactive diagnostic capability helps prevent undetected failures and ensures the integrity of the safety loop, which is vital for any gas detection system.

Innovation Point 3: Modular and Service-Oriented Design within System 57. As a part of the System 57 architecture, the 05701-A-0302 is designed for ease of maintenance and integration. Its hot-swappable nature allows for replacement without shutting down the entire system, minimizing downtime . The front-panel “Card Select” button simplifies interaction for commissioning and testing when used with a separate Engineering Card, streamlining the workflow for technicians .

Application Cases and Industry Value

The Honeywell 05701-A-0302 is pivotal in industries where monitoring for combustible gases is a critical safety requirement. In a chemical processing plant, for instance, these cards are deployed throughout the facility to monitor areas where flammable vapors might be released. Their ability to provide localized control and display, combined with system-wide alarm communication, allows for rapid incident response. A user case highlighted the card’s reliability in harsh environments, where its stable performance and low electronic drift (less than ±2% over six months) ensured consistent monitoring without frequent recalibration, leading to reduced maintenance costs and enhanced safety compliance .

Related Product Combination Solutions

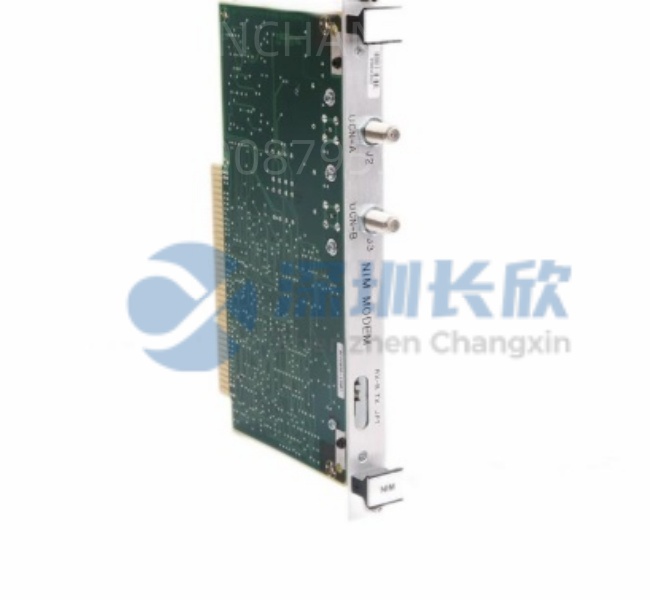

For a fully functional gas detection point, the Honeywell 05701-A-0302 requires and works with several related components within the System 57 framework :

Sensor Driver Modules: Such as the catalytic version (05701-A-0284) or the 4-20mA version (05701-A-0283), which interface directly with the physical sensor and connect to the control card .

Engineering Card (e.g., 05701-A-0361): Used for advanced configuration, calibration, and system setup of the control cards .

Other Control Card Variants: The 05701-A-0301 is a similar single-channel card designed for 4-20mA input, offering flexibility for different sensor types .

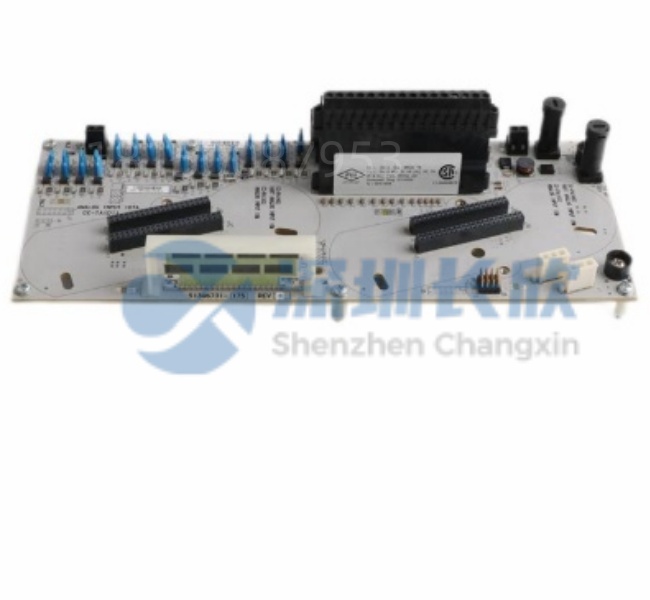

Analog Output Module (05701-A-0285): Can be used to output analog signals representing gas readings to a central DCS or PLC for broader plant monitoring .

Installation, Maintenance, and Full-Cycle Support

Installation of the Honeywell 05701-A-0302 involves mounting it within a System 57 chassis or panel, ensuring a stable DC power supply within the 18-32V range is connected . Proper connection to its designated Sensor Driver Module is crucial for accurate sensor readings. The modular and hot-swappable design significantly simplifies maintenance. If a fault is indicated by the diagnostics, a technician can replace the card without disrupting the entire gas detection system, after ensuring proper safety procedures are followed .

Routine maintenance primarily involves periodic functional checks and ensuring the front-panel display and alarms are operational. The built-in self-diagnostics provide continuous health monitoring. For full lifecycle support, it is recommended to source genuine Honeywell replacement parts and adhere to the manufacturer’s guidelines for calibration intervals to ensure the system remains in a state of operational readiness. Contact us for a customized solution or to discuss your specific application requirements.