TRICONEX 3009X

TRICONEX 3009X

好的,关于 TRICONEX 3009X 模块,我可以为您提供以下英文信息:

TRICONEX 3009X Module: A Comprehensive Overview

Product Overview

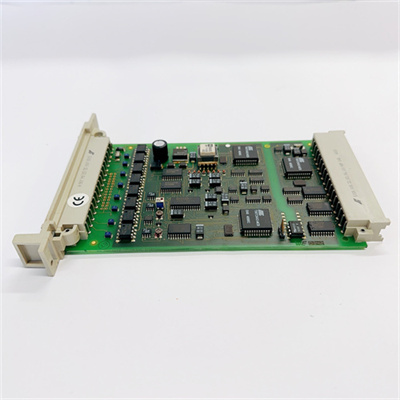

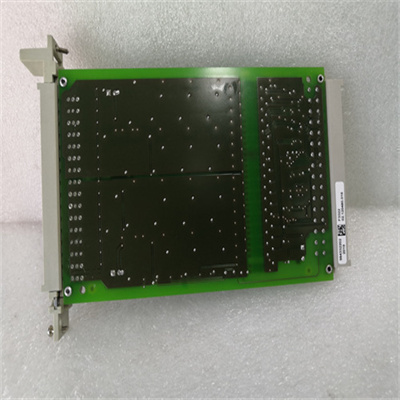

The TRICONEX 3009X is a high-performance main processor designed for safety-critical applications in industrial automation. It is part of the Triconex safety instrumented system (SIS) and plays a crucial role in providing reliable and redundant control for hazardous processes.

Key Features and Specifications

- Redundancy: Designed with triple modular redundancy (TMR) for enhanced reliability and fault tolerance.

- Processing Power: Powerful processor for handling complex control algorithms and large-scale systems.

- I/O Capabilities: Supports a wide range of I/O modules for various process variables.

- Communication: Offers multiple communication protocols for integration with other systems.

- Safety Certification: Certified to meet stringent safety standards, such as IEC 61508.

- Diagnostics: Built-in diagnostics for early detection of potential failures.

- Scalability: Can be configured to meet the specific needs of different applications.

Key Parameters (Typical Values)

- Operating Temperature: -20°C to +60°C

- Relative Humidity: 5% to 95% non-condensing

- Power Consumption: Varies based on configuration

- Dimensions: Refer to the product manual

- Weight: Refer to the product manual

Functions and Applications

- Safety Instrumented Systems (SIS): Provides the core processing for safety instrumented functions (SIFs) in hazardous industries.

- Process Control: Used in various process industries, such as oil and gas, chemical, and power generation.

- Safety Shutdown Systems: Ensures safe operation by initiating shutdown procedures in the event of hazardous conditions.

- Emergency Shutdown Systems: Provides rapid response to critical safety events.

Benefits

- High Reliability: TMR architecture ensures continuous operation even in the event of component failures.

- Safety: Certified to meet the highest safety standards.

- Flexibility: Can be configured to meet a wide range of application requirements.

- Scalability: Can be expanded to accommodate growing system needs.

- Compatibility: Works seamlessly with other Triconex components.

Additional Information

For detailed specifications, wiring diagrams, and programming instructions, please refer to the official product manual provided by Schneider Electric.

Key Points to Remember:

- End of Life: Please note that the TRICONEX 3009X has reached its end of life, meaning it is no longer actively supported by Schneider Electric.

- Replacement: If you are looking for a replacement, consider Schneider Electric’s newer safety instrumented systems, which offer advanced features and improved performance.

- Legacy Support: While the product is no longer supported, limited legacy support may be available from Schneider Electric or third-party providers.

Would you like to know more about specific aspects of the TRICONEX 3009X, such as its configuration options, compatibility with other devices, or migration to newer systems?

Please note that an image cannot be provided in a text-based format. You can search for an image of the TRICONEX 3009X module on the internet or in the product manual.

TRICONEX 3009X

TRICONEX 3009X

TRICONEX 3009X