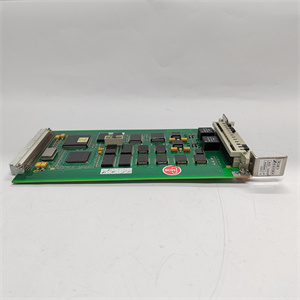

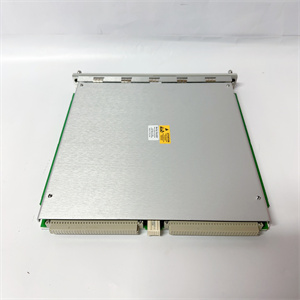

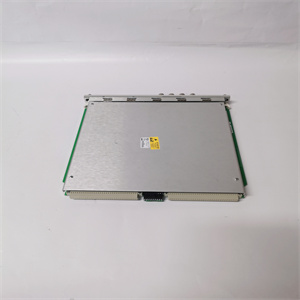

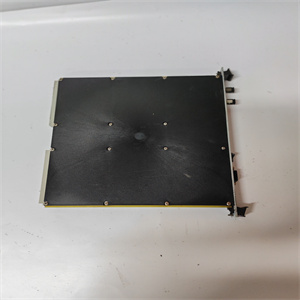

A-B 1756-TBCH A

Product Name: Allen-Bradley 1756-TBCH A Terminal Block

Manufacturer: Rockwell Automation

Product Type: Terminal Block

Product Description:

The Allen-Bradley 1756-TBCH A Terminal Block is a crucial component of the Allen-Bradley ControlLogix 1756 I/O system. It serves as a connection point for field devices to the controller, enabling the transfer of input and output signals.

A-B 1756-TBCH A

Key Features:

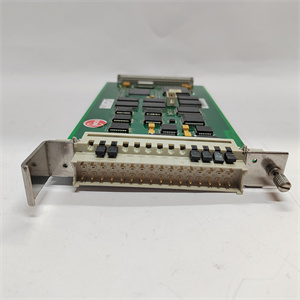

- High-Density Design: Accommodates a large number of I/O connections in a compact space

- Easy Installation: Simplifies installation and wiring with push-in terminals

- Secure Connections: Provides secure and reliable connections for signal transmission

- Durable Construction: Withstands harsh industrial environments

- Versatile Compatibility: Compatible with various Allen-Bradley ControlLogix 1756 controllers

Specifications:

- Number of Terminals: 32

- Terminal Type: Push-in terminals

- Wire Gauge: 14 AWG to 22 AWG

- Current Rating: 3 A per terminal

- Voltage Rating: 30 VDC or 24 VAC

- Operating Temperature: -40°C to +70°C (-40°F to +158°F)

- Protection Rating: IP20

- Dimensions: Approximately 165 x 38 x 23 mm (6.49 x 1.50 x 0.91 in)

- Weight: Approximately 150 g (5.3 oz)

-

A-B 1756-TBCH A

Applications:

- Connecting Field Devices: Interfacing various field devices, such as sensors, actuators, and switches, to the ControlLogix controller

- Input Signal Acquisition: Gathering input signals from field devices for monitoring and control purposes

- Output Signal Control: Sending output signals to field devices to control actuators, valves, and other devices

- Industrial Automation Systems: Implementing control and automation solutions in various industrial applications, including manufacturing, process control, and material handling

Overall, the Allen-Bradley 1756-TBCH A Terminal Block plays a vital role in connecting field devices to Allen-Bradley ControlLogix 1756 controllers, facilitating efficient signal transmission and enabling reliable control of various industrial processes.

Please note that the specific applications and functionalities of the terminal block may vary depending on the overall system configuration and the specific devices being connected.

A-B 1756-TBCH A (6)

125840-02 (2)

125840-02 (2)