BENTLY 60M100-00 Product Details

BENTLY 60M100-00 is a condition monitoring system produced by BENTLY NEVADA, which is mainly used for real-time monitoring and fault diagnosis of rotating machinery (such as turbines, compressors, etc.). The system can evaluate the operating status of the equipment by collecting data such as vibration, temperature, speed, etc., and provide early warning to prevent equipment failure and ensure production safety.

Main functions

Data acquisition: Collects a variety of sensor data such as vibration, temperature, speed, etc.

Signal processing: Analyze and process the collected data to extract key features.

Fault diagnosis: Evaluate the health status of the equipment according to the preset failure mode and threshold, and issue an alarm.

Trend analysis: Analyze the operating trend of the equipment and predict potential failures.

Report generation: Generate detailed monitoring reports for user analysis and maintenance.

Product features

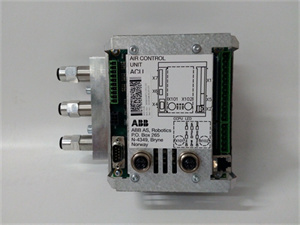

Modular design: The system adopts modular design and is easy to expand and maintain.

High reliability: It adopts industrial-grade design with high reliability and stability.

User-friendly: Provides an intuitive user interface and simple operation.

Powerful: Supports multiple analysis algorithms and diagnostic functions.

Application areas

Power industry: Monitoring and protection of rotating machinery such as generator sets and steam turbines.

Petrochemical industry: Monitoring and protection of rotating machinery such as compressors and pumps.

Metallurgical industry: Monitoring and protection of rotating machinery such as rolling mills and fans.

Technical parameters (typical values)

Sampling frequency: Configurable

Input channels: Multi-channel, can collect data from multiple sensors at the same time

Communication interface: Ethernet, RS232/485, etc.

Software platform: Bently Nevada System 1