GE WESDAC D20 PS Industrial Power Supply – High-Reliability DC Input for SCADA and Protection Systems

Description

The GE WESDAC D20 PS is a ruggedized, industrial-grade power supply module specifically engineered for the GE WESDAC D20 Remote Terminal Unit (RTU)—a foundational component in utility substation automation, SCADA, and protection systems. Designed to operate reliably under extreme electrical transients and wide ambient conditions, the GE WESDAC D20 PS converts high-voltage DC station battery power (typically 125 VDC or 250 VDC) into a tightly regulated 24 VDC output to power the D20’s CPU, I/O cards, and communication interfaces. Its compliance with IEEE 1613 and IEC 61850-3 ensures resilience in electrically noisy substation environments.

Application Scenarios

During a severe geomagnetic storm in the upper Midwest, a 230 kV transmission substation experienced repeated voltage sags and surges that tripped legacy power supplies in competing RTUs—causing loss of remote monitoring for over six hours. In contrast, the GE WESDAC D20 PS at a neighboring station maintained stable 24 VDC output despite input fluctuations from 85 VDC to 290 VDC, thanks to its wide-range design and robust filtering. The D20 RTU continued reporting breaker status, transformer load, and fault records in real time—enabling grid operators to reroute power and avoid cascading outages. In this critical moment, the GE WESDAC D20 PS proved that reliable power isn’t just about voltage—it’s about mission continuity.

Technical Principles and Innovative Values

Innovation Point 1: Substation-Hardened Design Without Derating

Unlike commercial PSUs, the GE WESDAC D20 PS operates at full 5 A load even at +70°C—critical for enclosed relay panels in desert or tropical climates.

Innovation Point 2: Seamless Integration with D20 Backplane

The GE WESDAC D20 PS delivers power directly through the RTU’s backplane, eliminating external wiring and reducing failure points in I/O signal paths.

Innovation Point 3: Immunity to Fast Transients (EFT) and Lightning Surges

Built-in multi-stage filtering and gas discharge tubes allow the GE WESDAC D20 PS to survive 4 kV burst tests per IEC 61000-4-4—common during switching operations in high-voltage yards.

Innovation Point 4: Legacy Compatibility with Modern Cybersecurity Upgrades

Though originally deployed in the 1990s, the GE WESDAC D20 PS continues to support modernized D20 systems with secure Ethernet gateways—ensuring decades-long asset life.

Application Cases and Industry Value

A Canadian hydroelectric utility retrofitted 32 aging substations with upgraded WESDAC D20 systems but retained original GE WESDAC D20 PS units due to their proven reliability. After 22 years in service—including exposure to −50°C winters and lightning-prone summers—not a single power module had failed. During a system audit, engineers measured output ripple at <50 mVpp, well within spec. The utility extended the service life of all GE WESDAC D20 PS units by another 10 years, saving an estimated $1.2M in replacement costs. As one senior engineer put it: “This power supply outlived three generations of software—and still runs like new.”

Related Product Combination Solutions

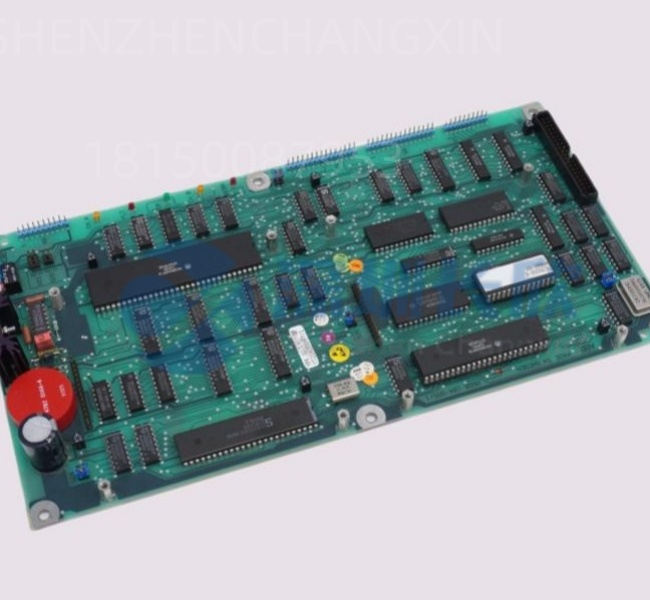

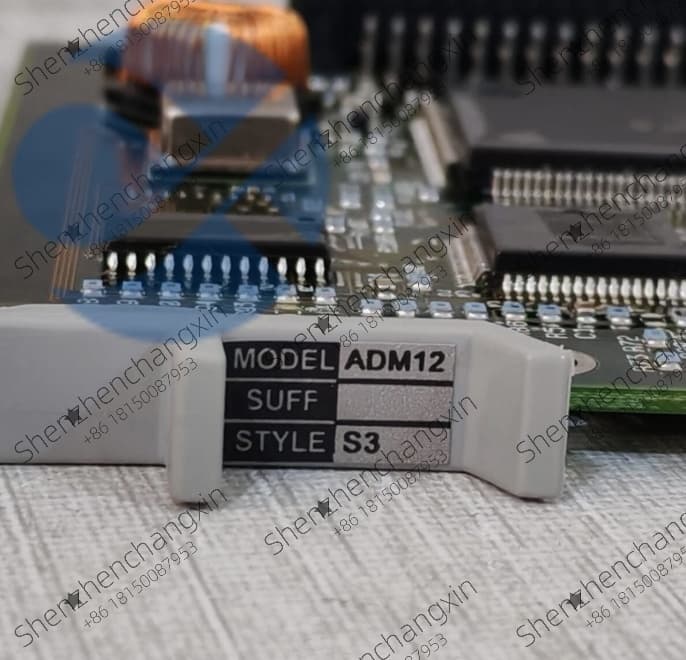

GE WESDAC D20 CPU: Main processor module—powered by the GE WESDAC D20 PS for data acquisition and protocol handling.

GE WESDAC D20 DI/DO Cards: Digital I/O modules—rely on stable 24 VDC from the GE WESDAC D20 PS for contact sensing and control.

GE Multilin 369: Motor protection relay—often co-located with D20 RTUs; shares the same station battery input.

GE D20ME: Enhanced D20 variant with Ethernet—still uses the same GE WESDAC D20 PS power architecture.

GE UR Series Relays (e.g., UR60): Can communicate with D20 via Modbus—both powered from redundant GE WESDAC D20 PS sources.

ABB REF615 or SEL-351: Third-party protection devices—integrated into D20 SCADA networks powered by the GE WESDAC D20 PS.

GE Grid IQ Insight: Cloud-based monitoring platform—depends on uninterrupted D20 operation enabled by reliable power from the GE WESDAC D20 PS.

Installation, Maintenance, and Full-Cycle Support

Installing the GE WESDAC D20 PS involves sliding it into the designated slot in the WESDAC D20 chassis, connecting station battery leads to its terminal block, and verifying output with a multimeter. The module features reverse-polarity protection and requires no configuration. For critical applications, two GE WESDAC D20 PS units can be installed in parallel for redundancy, with automatic load sharing.

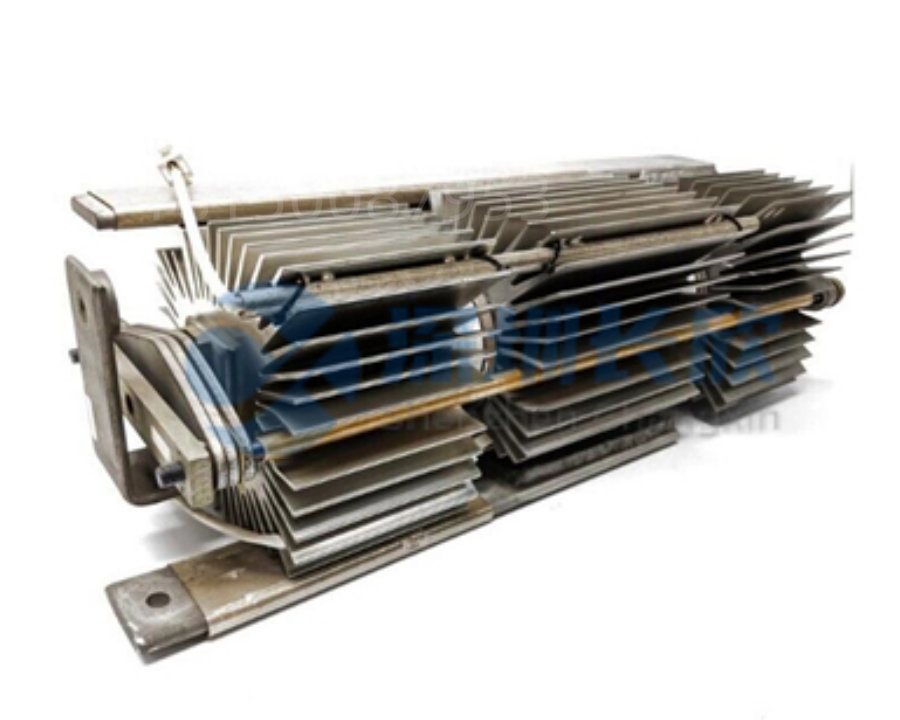

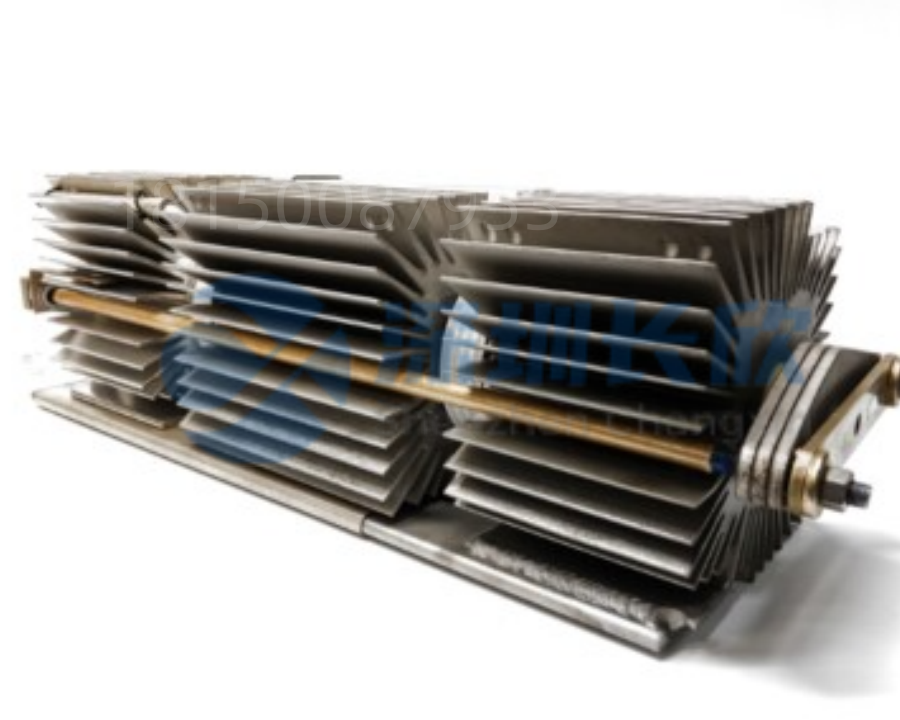

Maintenance is minimal—limited to visual inspection of LEDs and periodic cleaning of ventilation slots. The unit has no fans or electrolytic capacitors prone to drying out, contributing to its 20+ year field life. Our refurbished GE WESDAC D20 PS modules undergo:

Full load testing at min/max input voltages

Surge immunity validation (per IEEE 1613)

Thermal imaging under 70°C ambient

Backplane compatibility verification with D20 v3.x to v5.x firmware

We provide units with test reports, including efficiency curves and ripple measurements, and offer technical support for integration into legacy or hybrid substation architectures.

Contact us for a customized solution—including lifecycle extension, redundancy planning, or rapid deployment of certified GE WESDAC D20 PS power supplies to ensure your substation automation remains resilient, compliant, and always online.

Description

Description