Motorola MVME5500 Series 0161R | High-Performance PowerPC VME Module

Description

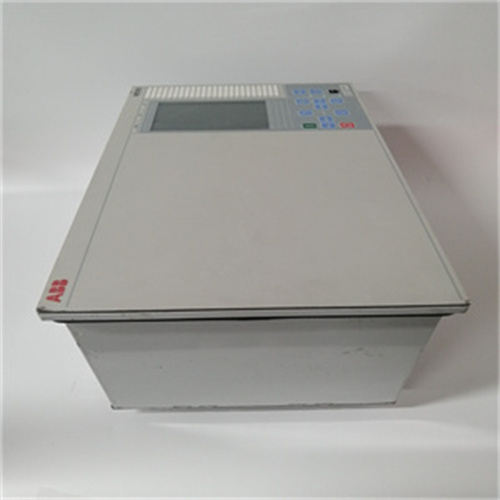

TheMOTOROLA MVME55006E-0161R is a high-performance, ruggedized Single Board Computer (SBC) from the renowned Motorola (later Emerson Network Power) MVME5500 series, designed for the VMEbus (VME64x) architecture. It is built around a powerful PowerPC 7448 processor and serves as a robust system controller or compute node in mission-critical embedded applications. This SBC integrates substantial processing power, memory, and versatile I/O on a 6U VME form factor, providing a reliable computing foundation for demanding real-time systems in military, telecommunications, and industrial automation.

Application Scenarios

In a coastal defense radar system, a rack of VME-based computers processes raw sensor data to track surface and air targets. The system controller, aMOTOROLA MVME55006E-0161R, is the computational cornerstone, responsible for fusing radar returns, running tracking algorithms, and coordinating with other system nodes. Its failure would degrade the entire site’s situational awareness. This SBC was selected for its balance of raw compute power (1GHz PowerPC), deterministic response, and ability to withstand the harsh, salt-spray prone environment. TheMVME55006E-0161R runs a real-time operating system like VxWorks, leveraging its dual Gigabit Ethernet ports to handle high-bandwidth sensor data and its PMC expansion site for a custom fiber-optic interface card. Its value is absolute reliability; it must process complex data streams 24/7 without fail, enabling operators to make split-second decisions. For legacy system sustainment engineers, finding a tested, compatibleMVME55006E-0161R is often the most cost-effective and low-risk solution to extend the service life of multi-million dollar defense or communication platforms for another decade.

Parameter

Main Parameters

Value/Description

Product Model

MVME55006E-0161R (Variant: -016 likely indicates 512MB DRAM)

Manufacturer

Motorola (Computer Group) / Emerson Network Power

Product Category

VME64x Single Board Computer (SBC) – 6U Form Factor

Central Processor

Motorola PowerPC 7448 (G4 core), 1 GHz.Delivers high performance with AltiVec SIMD for vector processing.

System Memory

512 MB of DDR SDRAM (with ECC).Provides ample, error-correcting memory for complex applications.

Non-Volatile Storage

64 MB of onboard Flash.Used for boot code, OS, and application storage.

Bus Architecture

VME64x (VMEbus).The industry-standard rugged backplane for military and industrial systems.

Key I/O Interfaces

Dual10/100/1000 Gigabit Ethernet, Dual Serial, USB,PMC (PCI Mezzanine Card) site.PMC allows for custom I/O expansion (e.g., additional comms, fiber).

Expansion Bus

PCI-X Interface.Provides a high-speed data path to the PMC site and other onboard peripherals.

Real-Time Clock

Yes, with battery backup.Critical for time-stamping and event logging in standalone systems.

Typical Use

System Controller in VME chassis for defense, telecom, simulation, and data acquisition.

Technical Principles and Innovative Values

TheMOTOROLA MVME55006E-0161R was engineered as a peak-performance VME SBC, leveraging advanced commercial computing technology within a rugged, embedded form factor.

Innovation Point 1: AltiVec-Accelerated Processing Power. The core innovation is the integration of the PowerPC 7448 CPU with itsAltiVec Velocity Engine. This Single Instruction, Multiple Data (SIMD) unit allows the processor to perform parallel operations on data vectors. For theMVME55006E-0161R, this meant dramatically accelerated performance in signal processing, image manipulation, and encryption algorithms—key workloads in radar, sonar, and communications systems—without requiring a separate, specialized DSP card.

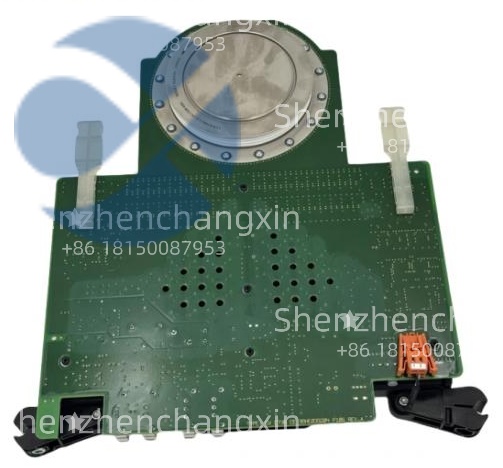

Innovation Point 2: Unified High-Bandwidth Architecture (CPU, Memory, I/O). The board was designed to eliminate bottlenecks. The high-speedMPC107 “Tsi107” Host Bridge/Memory Controller provided a low-latency, high-bandwidth pathway between the 1 GHz processor, the 512MB of fast DDR memory, and thePCI-X/PMC expansion bus. This unified architecture ensured that data from high-speed I/O (like a Gigabit Ethernet stream or a PMC-based data acquisition card) could flow efficiently to the CPU and memory, maximizing throughput for data-intensive real-time applications.

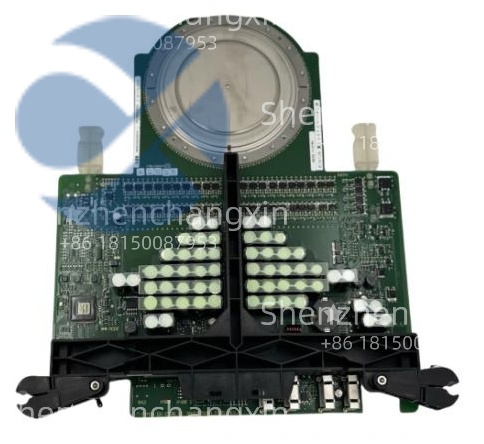

Innovation Point 3: The PMC Site for Application-Specific Customization. The inclusion of a high-performancePCI Mezzanine Card (PMC) site was a strategic innovation. It transformed theMVME55006E-0161R from a general-purpose computer into a customizable platform. System integrators could populate the PMC site with specialized cards for additional serial ports, fiber channel, analog I/O, or digital signal processing, tailoring the SBC to exact application needs without designing a new VME card from scratch. This drastically reduced development time and cost for OEMs.

Innovation Point 4: Ruggedness and Longevity for Deployed Systems. Beyond raw performance, the board was built to the demandingVITA 20 conduction-cooled standards (in its rugged variants) and used industrial-grade components. This focus on reliability over absolute cutting-edge speed made theMVME55006E-0161R a preferred choice for programs requiring long life cycles (10-15+ years) in challenging environments, where commercial servers would fail. Its design ensured stability under shock, vibration, and extended temperature ranges.

Application Cases and Industry Value

Case Study: Sustaining a Naval Combat System Console

A class of frigates uses a VME-based console system for its tactical picture compilation. The central computing nodes, based onMOTOROLA MVME55006E-0161R SBCs, aggregate data from radar, sonar, and off-board links. After 15 years of service, the original boards began experiencing memory errors due to aging. A full combat system replacement was budgetarily impossible and would require re-certification. The navy’s support team sourced certified, refurbishedMVME55006E-0161R units. The boards were drop-in replacements, booting the existing, certified VxWorks image and application software without modification. This swap restored full system reliability for a fraction of the cost of a new system, avoiding years of downtime and preserving the operational capability of the vessels. The program manager highlighted that the “form-fit-function compatibility of theMVME55006E-0161R was the only viable path to meeting our operational readiness targets within the fiscal constraints.”

Case Study: High-Throughput Data Acquisition in Test & Measurement

An aerospace contractor uses a large VME chassis to capture and process terabytes of data from flight test instrumentation. The system controller, anMVME55006E-0161R, manages a bank of specialized VME digitizer cards, streams the data to RAID arrays via its SCSI interface, and pre-processes it using its AltiVec unit. The requirement was sustained, high-bandwidth data movement with real-time processing. TheMVME55006E-0161R’s PCI-X to VME bridge and high-speed processor met this need where other boards bottlenecked. The engineers credited the board’s stability and powerful local processing with enabling them to perform more complex data reduction onboard before storage, speeding up post-flight analysis.

Related Product Combination Solutions

A functional system based on theMOTOROLA MVME55006E-0161R involves several complementary components.

MVME5500-0161 (Base Board): The standard commercial variant. TheMVME55006E-0161R is often a ruggedized or extended temperature version of this base board.

MVME7100 Transition Module: A critical companion board. It plugs into the P2/P0 connector of the SBC, breaking out its front-panel I/O (Ethernet, serial, USB) to standard connectors.

PMC Cards (e.g., MVME-050 or 3rd party): Expansion mezzanines. Examples include thePMC-4S1P (4-port serial card) or aPMC-FC (Fiber Channel) card to customize theMVME55006E-0161R’s I/O capabilities.

VME Chassis: A 6U VME64x backplane chassis, such as those fromEmerson (MVME2100/2300 series) orKontron. Provides power, cooling, and the data bus.

VxWorks 5.5/6.x or Linux (PowerPC): The operating systems most commonly deployed. A Board Support Package (BSP) specific to theMVME55006E-0161R is required.

Tsi107 Driver & Firmware: Low-level software essential for initializing the memory controller and PCI-X bridge on the board.

Installation, Maintenance, and Full-Cycle Support

Installation of theMOTOROLA MVME55006E-0161R requires careful ESD handling and familiarity with VME systems. The board is carefully aligned with the guide rails of a 6U VME slot and firmly pressed into the J1/P1 and J2/P2 backplane connectors until fully seated, then secured with front panel screws. Critical pre-installation steps include verifying the VME chassis IP address switch settings (if used) and ensuring correct termination. TheMVME7100 transition module must be attached to the front for I/O connectivity. Initial boot is typically performed via a serial console to access the Board’s Firmware (PROM) to set boot parameters, such as defining boot source (Flash, network via BOOTP/DHCP) and configuring the onboard Gigabit Ethernet ports.

Routine maintenance involves monitoring the system’s environmental health (temperature) and ensuring the cooling filters in the chassis are clean. The most common service action is the proactive replacement of theLithium battery for the real-time clock and configuration storage before it fails and causes settings loss. Troubleshooting a non-booting board follows a standard hierarchy: verify power and status LEDs, check serial console for firmware messages, test with minimal configuration (single DRAM DIMM if applicable), and reseat the board and transition module. Due to the complexity of BGA (Ball Grid Array) packages, component-level repair is highly specialized.

Our support for theMOTOROLA MVME55006E-0161R is tailored to the needs of organizations maintaining legacy embedded systems. We supply fully tested and validated boards, often sourced from decommissioned but known-good systems. We provide technical documentation, including hardware manuals and reference guides for jumper settings and firmware updates. We understand the criticality of firmware and BSP compatibility and can often advise on or supply the correct versions. For integration challenges, we offer access to engineers familiar with the MVME5500 ecosystem. Our goal is to be your partner in legacy system sustainment, providing the reliable hardware and knowledge needed to keep your critical applications running.

.jpg)