GE H201Ti is a device widely used in industrial automation and power system monitoring.The following is a detailed introduction to the device:

I.Product Overview

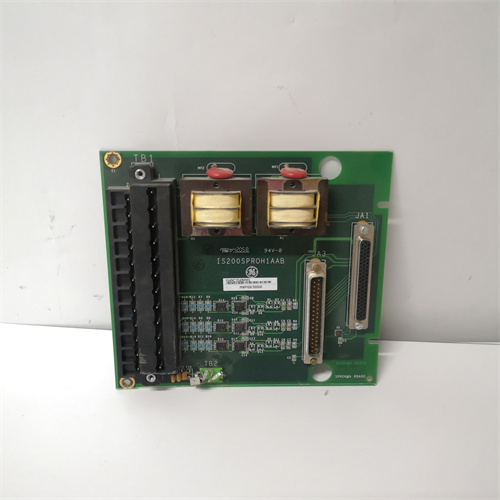

GE H201Ti is a microprocessor-based electric transmitter,which is often used as a continuous dissolved gas analysis(DGA)monitor in oil.The device can monitor fault gases such as hydrogen(H2),carbon monoxide(CO),acetylene(C2H2)and ethylene(C2H4)in transformers,providing early warning to personnel,thereby minimizing unplanned power outages.

GE H201Ti

II.Main functions and features

High-precision monitoring:

GE H201Ti is equipped with a high-precision HYDRAN®sensor that can accurately monitor the content of dissolved gases in transformers.

The device has a local data record and major event record for up to one year,which helps to analyze the cause and trend of failures.

Early warning system:

GE H201Ti can provide personnel with a single reading(ppm)of various fault gas composite valuesto alert them to potential problems.

Users can download these readings and set alarms at predetermined levels to receive timely reminders when gas levels reach dangerous levels.

Remote Monitoring and Communication:

GE H201Ti has local and remote alarm functions that can be set at predefined levels or rates of change.

The device communicates via a serial port,allowing remote viewing of gas readings and trends,facilitating real-time monitoring and troubleshooting by staff.

Adaptable:

GE H201Ti can adapt to different working environments and transformer types.

It is directly connected to the transformer’s dissolved gas monitoring valve through a brass adapter,which is easy and quick to use.

Simple Maintenance:

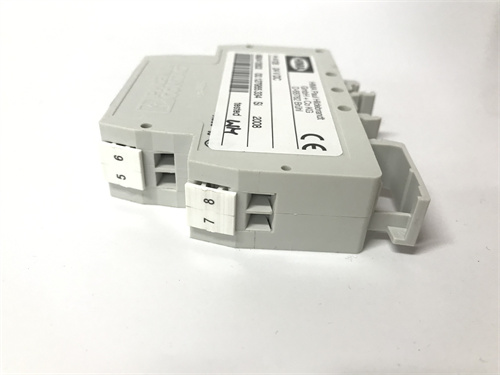

GE H201Ti’s terminals facilitate connection to AC power,alarm contacts(gas high,gas high-high and system fault)and regulatory connections.

The device is easy to maintain and maintain,reducing operation and maintenance costs.

III.Application Fields

GE H201Ti is widely used in various occasions where transformer fault gas needs to be monitored,including but not limited to:

Power system:used to monitor fault gas in power transformers to ensure the stable operation of the power system.

GE H201Ti

Industrial Automation:In industrial automation systems,GE H201Ti can be used as an important monitoring device for detecting and analyzing equipment failures.

Petroleum and Chemical Industry:In the petroleum and chemical industry,the device can be used to monitor the gas content in reactors and storage tanks to ensure production safety.

IV.Technical Specifications

The technical specifications of the GE H201Ti may vary depending on the specific model and configuration,but generally include the following:

Measurement range:Gas content range is 0-2000ppm(equivalent hydrogen volume/volume).

Accuracy:At a set point of 35℃,the accuracy of gas readings is±10%,±25%ppm(equivalent hydrogen).

Gas relative sensitivity:100%for hydrogen(H2),18±3%for carbon monoxide(CO),8±2%for acetylene(C2H2),and 1.5±0.5%for ethylene(C2H4).

Power supply:Usually powered by AC power.

Communication interface:Supports serial port communication for convenient remote monitoring and data transmission.

The company mainly imports PLC modules,programmable controllers,servo control systems and DCS spare parts,such as:ABB,AB(Rockwell),GE(General Electric),Bentley,Honeywell Er),Emerson.),Motorola,Invensys,Westinghouse,etc.The company has established close cooperative relations with many world-renowned PLC and DCS product maintenance service providers.We can purchase goods directly from abroad and provide equipment and spare parts from different countries and manufacturers.

We supply goods directly from abroad,without intermediaries,reducing the cost of use.

There is really no medium that can make a difference!!

Shenzhen Changxin Automation-sufficient supply,large spot quantity,guaranteed quality,you can buy with confidence and use with peace of mind~!

If you have any defects or needs for imported PLC and DCS spare parts,please contact our team,we will help you find reliable and high-quality products super quickly,while shortening delivery time to ensure that your equipment can operate normally in the right environment.Just in time.

Professionally provide:PLC programmable control system,distributed control system(DCS),safety instrument system(SIS),ESD system,vibration monitoring system,turbo compressor unit control system(CCS)and other PLC modules,various industrial control systems,system modules,CPU,IO module,DO module,AI module,DI module,network communication module,Ethernet module,motion controller,analog input module,analog output module,digital input module,digital output module,module redundancy,power module,relay output unit,relay input unit,processor unit.

Products are widely used in:electricity,petroleum,mine hoisting,ports,heating,gas,water supply,sewage treatment,metallurgy,papermaking,textile,chemical industry,water conservancy and other modern industrial fields!

1.”Power plant DCS monitoring system”

2.”Intelligent flat tempering furnace system manufacturing”

3.”PLC programmable transmission control system”

4.”DCS distributed control system”

5.”Intelligent fire water suppl