GE ESM10A is a high-performance programmable logic controller(PLC)designed for industrial automation applications.The following is a detailed introduction to GE ESM10A:

1.Product Overview

GE ESM10A is part of the extensive automation product line of GE Fanuc Intelligent Platform,providing reliable and versatile solutions for controlling various industrial processes.It has a rugged structure designed for harsh industrial environments and can withstand extreme temperatures,vibrations and shocks.

GE ESM10A

2.Main Features

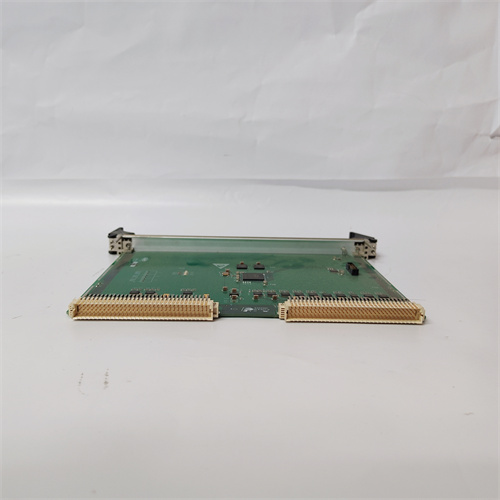

High-performance processor:ESM10A is equipped with a high-performance processor that can execute control programs quickly and efficiently,ensuring real-time and accuracy.

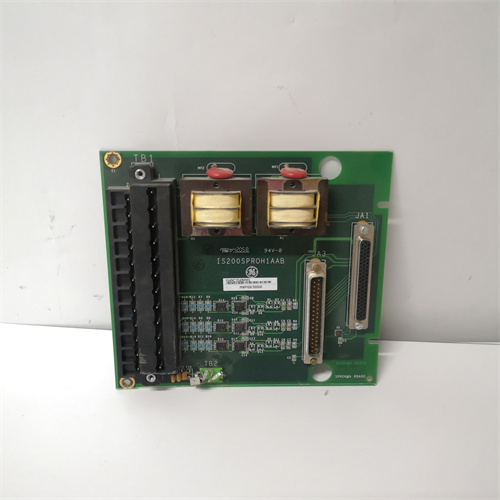

Flexible I/O configuration:The module provides flexible I/O configuration with a variety of digital and analog input/output channels to meet various application requirements.This provides great convenience for users and can be customized according to the actual application scenario.

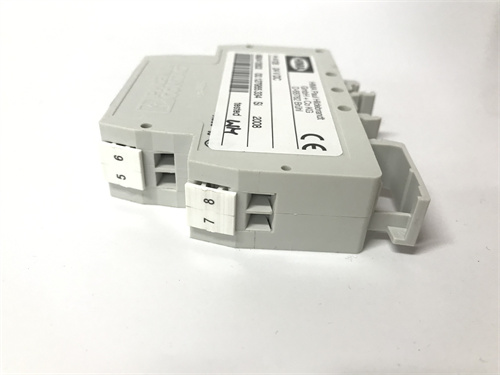

Compact design:ESM10A is installed in a compact DIN rail mounting housing,saving control cabinet space and making equipment layout and installation more convenient.

Multiple programming language support:ESM10A can be programmed in a variety of languages,including IEC 61131-3(ladder logic),structured text,and function block diagrams.This provides users with a variety of programming options,and they can choose the appropriate language according to their personal programming habits and project requirements.

Powerful communication capabilities:ESM10A supports multi-port physical and serial communications,as well as Ethernet communication functions.Through the Ethernet interface,the device can be easily connected to the network for remote monitoring,data acquisition,and control.In addition,it also supports a variety of communication protocols,such as Modbus TCP,and can seamlessly connect with a variety of devices and systems.

Analog input interface:ESM10A provides 16 channels of 16-bit A/D interface signals and supports a variety of I/O ranges,such as±20mA,0-20mA,or 4-20mA DC current input,and±5V or±10V DC voltage input.This provides users with a wealth of analog signal input options.

Data register support:ESM10A’s dual-format data registers support 16-bit integer and 32-bit floating point formats.Users can read raw channel data based on 16-bit signed integers or 32-bit scaled registers,and can be configured by channel.

3.Application Fields

GE ESM10A controller circuit boards are commonly used in various industrial automation applications,including but not limited to:

Machine control:Control the operation of machines and production lines to ensure the smooth progress of the production process.

GE ESM10A

Process control:Regulate and optimize industrial processes,such as temperature,pressure and flow control,to improve production efficiency and product quality.

Conveyor belt control:Manage the movement of materials and products on the conveyor belt system to achieve automated material handling and production line scheduling.

Robotics and automation:Control robotic arms,manipulators and other automation systems to improve the automation level and production efficiency of production lines.

Building automation:Manage building systems such as HVAC(heating,ventilation and air conditioning),lighting and security,etc.,to improve the intelligence level and energy utilization efficiency of buildings.

4.Technical Specifications

Here are some key technical specifications of the GE ESM10A:

Processor:High-performance processor

I/O channels:16 digital inputs,16 digital outputs,4 analog inputs,2 analog outputs

Communications:RS485,Modbus TCP

Power supply:24 VDC

Power consumption:10 W

Operating temperature range:-20°C to+60°C(-4°F to+140°F)

Humidity:0%to 95%RH(non-condensing)

Vibration:0.03 in.peak-to-peak,10 to 500 Hz

Shock:15 G,11 ms,half-sine wave

Dimensions:96 x 63 x 26 mm(3.78 x 2.48 x 1.02 in.)

Weight:0.2 kg(0.4 lbs.)

The company mainly imports PLC modules,programmable controllers,servo control systems and DCS spare parts,such as:ABB,AB(Rockwell),GE(General Electric),Bentley,Honeywell Er),Emerson.),Motorola,Invensys,Westinghouse,etc.The company has established close cooperative relations with many world-renowned PLC and DCS product maintenance service providers.We can purchase goods directly from abroad and provide equipment and spare parts from different countries and manufacturers.

We supply goods directly from abroad,without intermediaries,reducing the cost of use.

There is really no medium that can make a difference!!

Shenzhen Changxin Automation-sufficient supply,large spot quantity,guaranteed quality,you can buy with confidence and use with peace of mind~!

If you have any defects or needs for imported PLC and DCS spare parts,please contact our team,we will help you find reliable and high-quality products super quickly,while shortening delivery time to ensure that your equipment can operate normally in the right environment.Just in time.

Professionally provide:PLC programmable control system,distributed control system(DCS),safety instrument system(SIS),ESD system,vibration monitoring system,turbo compressor unit control system(CCS)and other PLC modules,various industrial control systems,system modules,CPU,IO module,DO module,AI module,DI module,network communication module,Ethernet module,motion controller,analog input module,analog output module,digital input module,digital output module,module redundancy,power module,relay output unit,relay input unit,processor unit.

Products are widely used in:electricity,petroleum,mine hoisting,ports,heating,gas,water supply,sewage treatment,metallurgy,papermaking,textile,chemical industry,water conservancy and other modern industrial fields!

1.”Power plant DCS monitoring system”

2.”Intelligent flat tempering furnace system manufacturing”

3.”PLC programmable transmission control system”

4.”DCS distributed control system”

5.”Intelligent fire water suppl