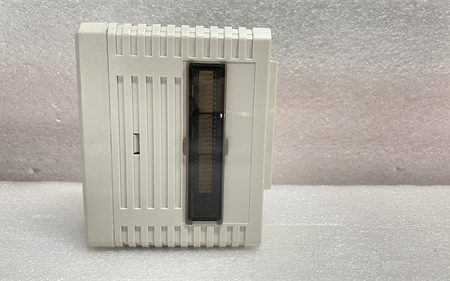

PFEA113-65 3BSE028144R0065 is a high-performance tension control device launched by ABB.The following is a detailed introduction to the device:

1.Product Overview

PFEA113-65 3BSE028144R0065 tension controller combines advanced control algorithms and precise measurement technology to achieve precise tension control of various coils,strips or continuous materials in the production process.It is suitable for various application scenarios that require constant tension control,such as production lines for wires and cables,plastic films,paper,textiles,etc.

ABB PFEA113-65 3BSE028144R0065

2.Main features

High-precision measurement and control:

It has high-precision tension measurement capabilities and can quickly respond to tension changes.

Achieve stable tension control through precise control algorithms.

Multiple control modes:

Support multiple tension control modes,such as constant tension control,speed-related tension control,etc.

To meet the needs of different production processes.

Excellent dynamic performance:

The tension can be adjusted quickly during coil acceleration,deceleration or speed change.

Maintain stable tension control,reduce material waste and improve product quality.

Easy integration and debugging:

Provide standard interfaces and communication protocols for easy integration with other automation equipment and systems.

The debugging process is simple and intuitive,reducing the complexity of installation and maintenance.

High reliability:

Adopt high-quality hardware components and strict production processes.

Ensure that the equipment can operate stably even in harsh industrial environments.

User-friendly interface:

Equipped with an intuitive user interface such as a touch screen or LED display.

Convenient for operators to monitor and adjust parameters.

Powerful diagnostic function:

Equipped with complete fault diagnosis and alarm functions.

Can help operators quickly locate problems and deal with them.

III.Application field

PFEA113-65 3BSE028144R0065 tension controller plays a key role in many industries to ensure product quality and process stability.Specific application areas include:

Printing and transfer industry:

In printing machinery and transfer equipment,the tension controller is used to ensure that the web maintains proper tension throughout the printing or transfer process to obtain printing quality and accurate position.

ABB PFEA113-65 3BSE028144R0065

Paper and packaging industry:

During coil and paper processing,tension controllers are used to control the tension of coils to prevent stretching,twisting or breaking of paper or packaging materials.

Metal processing:

In the metal processing industry,especially in coil processing,tension controllers help ensure that metal strips or coils maintain proper tension during shearing,stretching and punching.

Textile industry:

In textile production,tension controllers are used to maintain the tension of fibers,wires or fabrics to ensure consistent product quality during weaving and processing.

Cigarette manufacturing:

In cigarette production,tension controllers are used to maintain proper tension in cigarette paper coils to ensure uniformity and quality of cigarettes.

Plastic film production:

In plastic film production,tension controllers help maintain the tension of plastic coils to ensure the stability of the film during winding and processing.

IV.Product advantages

Improve production efficiency:

Precise tension control helps reduce material waste and defective rate.

Improve the overall production efficiency of the production line.

Improve product quality:

Stable tension control helps ensure product consistency and quality.

Enhance the market competitiveness of products.

Reduce maintenance costs:

Easy integration and debugging reduce the complexity of installation and maintenance.

Reduce downtime and repair costs caused by equipment failure.

Enhance system reliability:

High-quality hardware components and strict production processes ensure the stability and reliability of the equipment.

Improve the reliability and stability of the entire production system.

The company mainly imports PLC modules,programmable controllers,servo control systems and DCS spare parts,such as:ABB,AB(Rockwell),GE(General Electric),Bentley,Honeywell Er),Emerson.),Motorola,Invensys,Westinghouse,etc.The company has established close cooperative relations with many world-renowned PLC and DCS product maintenance service providers.We can purchase goods directly from abroad and provide equipment and spare parts from different countries and manufacturers.

We supply goods directly from abroad,without intermediaries,reducing the cost of use.

There is really no medium that can make a difference!!

Shenzhen Changxin Automation-sufficient supply,large spot quantity,guaranteed quality,you can buy with confidence and use with peace of mind~!

If you have any defects or needs for imported PLC and DCS spare parts,please contact our team,we will help you find reliable and high-quality products super quickly,while shortening delivery time to ensure that your equipment can operate normally in the right environment.Just in time.

Professionally provide:PLC programmable control system,distributed control system(DCS),safety instrument system(SIS),ESD system,vibration monitoring system,turbo compressor unit control system(CCS)and other PLC modules,various industrial control systems,system modules,CPU,IO module,DO module,AI module,DI module,network communication module,Ethernet module,motion controller,analog input module,analog output module,digital input module,digital output module,module redundancy,power module,relay output unit,relay input unit,processor unit.

Products are widely used in:electricity,petroleum,mine hoisting,ports,heating,gas,water supply,sewage treatment,metallurgy,papermaking,textile,chemical industry,water conservancy and other modern industrial fields!

1.”Power plant DCS monitoring system”

2.”Intelligent flat tempering furnace system manufacturing”

3.”PLC programmable transmission control system”

4.”DCS distributed control system”

5.”Intelligent fire water suppl

Reviews

There are no reviews yet.