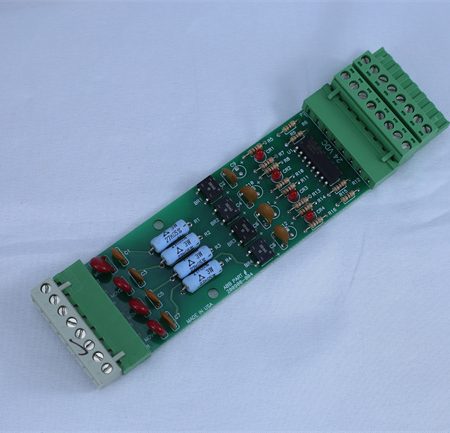

MMS6120 is a dual-channel bearing vibration measurement module.The following is a detailed introduction to it:

1.Product Overview

MMS6120 is produced by well-known manufacturers(such as Emerson EPRO,etc.)and is a module specifically used to measure bearing vibration.It adopts a dual-channel design and can monitor the vibration signals of two channels at the same time.It is suitable for various types of turbomachinery,such as steam turbines,gas turbines,compressors,fans,gearboxes,blowers,centrifuges,etc.

2.Functional Features

Dual-channel measurement:MMS6120 has two independent measurement channels and can receive and process the vibration signals of two bearings at the same time.

High-precision measurement:The module can measure the vibration of the bearing with high precision to ensure the accuracy and reliability of the data.

Multiple functions:In addition to basic vibration measurement,MMS6120 also provides alarm,sensor power supply,module power supply,channel and sensor detection and signal filtering.

Programmability:The module has a built-in microprocessor,which can set the working mode and parameters through the field portable machine or remote communication bus,read all measurement values,and perform spectrum analysis.

Data storage:The last start/stop process is stored in the module and can be displayed by a computer for subsequent analysis and troubleshooting.

III.Technical specifications

Input signal:Usually used in conjunction with an electric speed sensor to receive the vibration signal output by the sensor.

Output signal:Convert the sensor input signals of the two channels into standard signal outputs,such as 420mA or 010V,etc.

Power supply voltage:Generally 24VDC to ensure the stable operation of the module.

Communication interface:Provides RS232/485 and other communication interfaces for on-site configuration and communication,and can read out the measured values.

Working environment:Suitable for various harsh industrial environments,with excellent stability and durability.

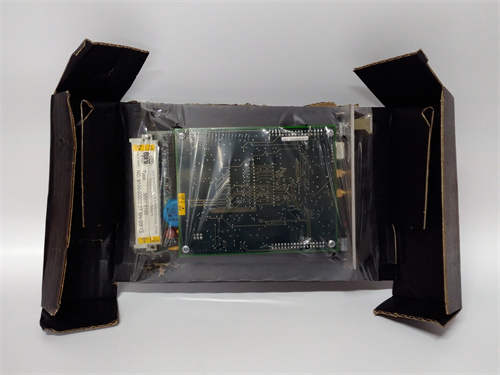

MMS6120

IV.Application scenarios

MMS6120 is widely used in various industrial occasions that require monitoring of bearing vibration,such as power plants,chemical plants,steel plants,etc.It can be integrated with other monitoring equipment and control systems to achieve real-time monitoring and protection of turbomachinery and improve the operating efficiency and safety of equipment.

The company mainly imports PLC modules,programmable controllers,servo control systems and DCS spare parts,such as:ABB,AB(Rockwell),GE(General Electric),Bentley,Honeywell Er),Emerson.),Motorola,Invensys,Westinghouse,etc.The company has established close cooperative relations with many world-renowned PLC and DCS product maintenance service providers.We can purchase goods directly from abroad and provide equipment and spare parts from different countries and manufacturers.

We supply goods directly from abroad,without intermediaries,reducing the cost of use.

There is really no medium that can make a difference!!

Shenzhen Changxin Automation-sufficient supply,large spot quantity,guaranteed quality,you can buy with confidence and use with peace of mind~!

If you have any defects or needs for imported PLC and DCS spare parts,please contact our team,we will help you find reliable and high-quality products super quickly,while shortening delivery time to ensure that your equipment can operate normally in the right environment.Just in time.

Professionally provide:PLC programmable control system,distributed control system(DCS),safety instrument system(SIS),ESD system,vibration monitoring system,turbo compressor unit control system(CCS)and other PLC modules,various industrial control systems,system modules,CPU,IO module,DO module,AI module,DI module,network communication module,Ethernet module,motion controller,analog input module,analog output module,digital input module,digital output module,module redundancy,power module,relay output unit,relay input unit,processor unit.

Products are widely used in:electricity,petroleum,mine hoisting,ports,heating,gas,water supply,sewage treatment,metallurgy,papermaking,textile,chemical industry,water conservancy and other modern industrial fields!

1.”Power plant DCS monitoring system”

2.”Intelligent flat tempering furnace system manufacturing”

3.”PLC programmable transmission control system”

4.”DCS distributed control system”

5.”Intelligent fire water suppl

Reviews

There are no reviews yet.