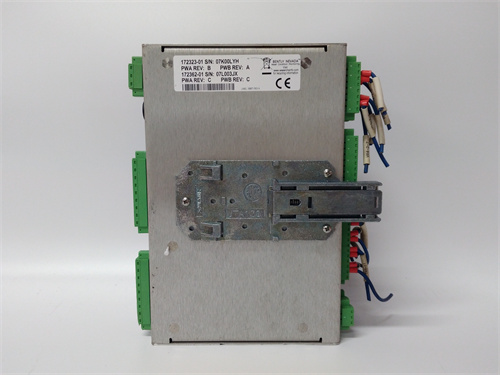

BENTLY 1900-65A is a mechanical condition monitoring device,which is often used to continuously monitor and protect various industrial and mechanical equipment.The following is a detailed introduction to BENTLY 1900-65A:

1.Main features

Multi-channel input and output:

BENTLY 1900-65A provides four sensor inputs and four temperature inputs,which can meet the monitoring needs of a variety of equipment.

Sensor input supports 2-wire and 3-wire accelerometers,velocity sensors or proximity sensors.

Temperature input supports E,J,K and T type thermocouples and 2-wire or 3-wire thermal resistors.

Multiple output options:

The device provides six relay outputs,four 4-20 mA recorder outputs and one dedicated buffer output.

Relay outputs can be used to control a variety of electrical equipment and mechanical equipment.

Recorder outputs can provide data from any variable from any channel.

1900-65A

Programmability and flexibility:

Users can use the 1900 configuration software to program relay contacts to open or close based on the determination,alarm and dangerous status of any channel or channel combination.

Dedicated buffered outputs provide signals for each sensor input,increasing the flexibility of the device.

Communication interface:

BENTLY 1900-65A supports Modbus communication via Ethernet and software-configurable RS232/485 serial ports.

This enables the device to easily exchange data and integrate with other systems.

Easy configuration and maintenance:

Users can create configuration files using software running on a laptop or PC and download the files to the monitor via the built-in Ethernet connection.

Configuration information can be permanently saved in non-volatile memory and can be uploaded to the PC for changes.

High reliability and stability:

BENTLY 1900-65A uses high-quality materials and manufacturing processes to ensure stable operation even in harsh working environments.

After strict quality control and testing,it has high reliability and stability.

1900-65A

2.Application areas

BENTLY 1900-65A is widely used in the condition monitoring of various industrial and mechanical equipment,including but not limited to:

Equipment monitoring of power plants and power systems

Equipment condition monitoring in the petroleum,chemical and metallurgical industries

Vibration monitoring of mechanical manufacturing and processing equipment

Condition monitoring and fault warning of transportation equipment

The company mainly imports PLC modules,programmable controllers,servo control systems and DCS spare parts,such as:ABB,AB(Rockwell),GE(General Electric),Bentley,Honeywell Er),Emerson.),Motorola,Invensys,Westinghouse,etc.The company has established close cooperative relations with many world-renowned PLC and DCS product maintenance service providers.We can purchase goods directly from abroad and provide equipment and spare parts from different countries and manufacturers.

We supply goods directly from abroad,without intermediaries,reducing the cost of use.

There is really no medium that can make a difference!!

Shenzhen Changxin Automation-sufficient supply,large spot quantity,guaranteed quality,you can buy with confidence and use with peace of mind~!

If you have any defects or needs for imported PLC and DCS spare parts,please contact our team,we will help you find reliable and high-quality products super quickly,while shortening delivery time to ensure that your equipment can operate normally in the right environment.Just in time.

Professionally provide:PLC programmable control system,distributed control system(DCS),safety instrument system(SIS),ESD system,vibration monitoring system,turbo compressor unit control system(CCS)and other PLC modules,various industrial control systems,system modules,CPU,IO module,DO module,AI module,DI module,network communication module,Ethernet module,motion controller,analog input module,analog output module,digital input module,digital output module,module redundancy,power module,relay output unit,relay input unit,processor unit.

Products are widely used in:electricity,petroleum,mine hoisting,ports,heating,gas,water supply,sewage treatment,metallurgy,papermaking,textile,chemical industry,water conservancy and other modern industrial fields!

1.”Power plant DCS monitoring system”

2.”Intelligent flat tempering furnace system manufacturing”

3.”PLC programmable transmission control system”

4.”DCS distributed control system”

5.”Intelligent fire water suppl

Reviews

There are no reviews yet.