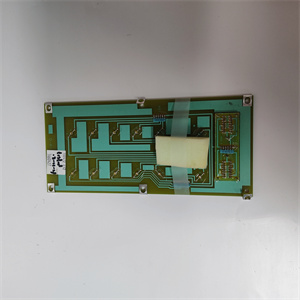

BENTLY 125840-01 2

Product Information for BENTLY 125840-01 in English:

Product Parameters:

- Model Number: 125840-01

- Manufacturer: Bently Nevada (a part of Emerson Automation Solutions)

Specifications:

- Speed Range (for vibration monitoring variant): 10 to 20,000 RPM1

- Sensitivity (for vibration monitoring variant): 0.001 to 10g/mm1

- Frequency Range (for vibration monitoring variant): 5 to 2,000 Hz1

- Output Signal (for vibration monitoring variant): 4 to 20 mA1

- Environmental Protection: IP651

- Power Supply Voltage: 24VDC1

- Power Consumption: 5W1

- Operating Temperature Range: -40°C to +85°C (-40°F to +185°F)1

For Other Variants (e.g., Motion Controller or Transient Data Interface Module):

- Input Voltage Range: 12-48VDC2

- Output Voltage Range: 5VDC2

- Output Current: Maximum 10A2

- Efficiency: Greater than 90%2

- CPU: 32-bit RISC processor2

- Operating Temperature: -20°C to +50°C2

- Storage Temperature: -40°C to +70°C2

- Humidity: 5% to 95% RH (non-condensing)2

Dimensions & Weight:

- Size (for vibration monitoring variant): Not specifically mentioned, but similar products in the series may have comparable dimensions.

- Weight (for vibration monitoring variant): 0.6kg1

- For other variants, weights and sizes may differ. For example, the Transient Data Interface Module is mentioned to be 170mm x 105mm x 32mm and weigh approximately 120g2.

Series:

- Part of the Bently Nevada 3500 series bearing vibration monitoring system1. It may also be used in other industrial automation contexts as a motion controller or data interface module23.

Features:

- High-Precision Measurement: For vibration monitoring, it provides precise measurement of vibration levels and speeds1.

- Programmable Logic Control: As a motion controller module, it supports various programming languages and custom control logic3.

- Integrated Communication: Offers seamless integration with other industrial systems, sensors, and actuators through various communication protocols3.

- Reliability and Durability: Designed for long-term, reliable operation in harsh industrial environments13.

- Advanced Protection: For power control variants, it offers overvoltage, overcurrent, and thermal shutdown protection4.

Application/Function:

- Vibration Monitoring: Used in industrial equipment to monitor and detect bearing and machinery vibrations, enhancing equipment reliability and preventing failures1.

- Motion Control: In industrial automation systems, it provides precise control of motors, actuators, and other devices, suitable for applications requiring high-precision motion control, such as robotic arms, conveyor belts, and assembly lines3.

- Data Interface: Acts as a transient data interface module, facilitating data exchange between various industrial systems and devices2.

Note: The specifications, features, and applications mentioned above may vary depending on the exact product variant and manufacturer’s specifications. Always consult the official product documentation or contact the manufacturer directly for the most accurate and up-to-date information.

参考:

1|深圳长欣自动化设备有限公司

2|爱企查

3|哔哩哔哩

4|哔哩哔哩

BENTLY 125840-01 2

BENTLY 125840-01 2