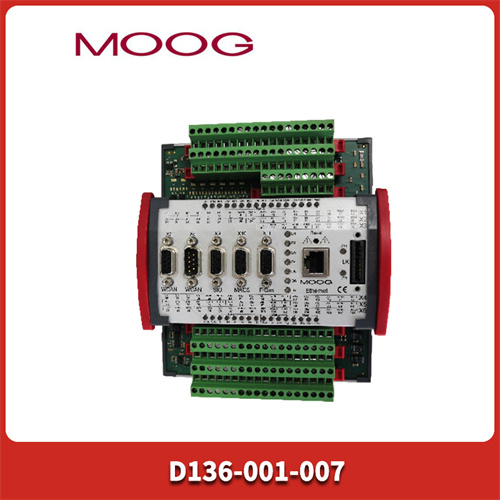

MOOG D136-001-007.1

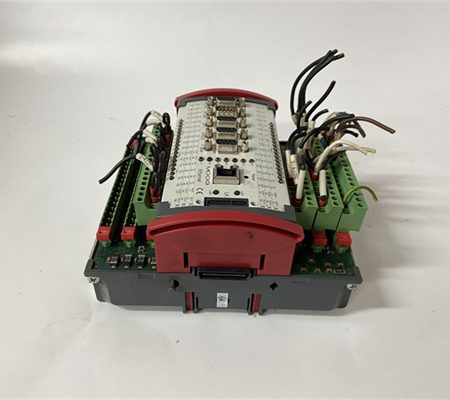

The MOOG D136-001-007 product, while the exact version you’ve mentioned as “D136-001-007.1” might be a typo or a specific variant not explicitly detailed in the publicly available information, I can provide a summary of the MOOG D136-001-007 product parameters, specifications, dimensions, weight, series, features, and applications in English based on the information gathered.

Product Overview:

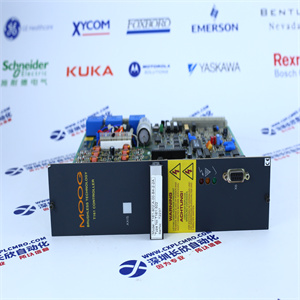

The MOOG D136-001-007 is a high-performance servo controller from MOOG, a renowned manufacturer of motion control systems and components. This servo controller is designed for precise and efficient control of industrial automation systems.

Product Parameters and Specifications:

- Brand: MOOG

- Model: D136-001-007

- Type: Servo Controller with PLC Functionality

- Ethernet: Supported1

- CAN/CANopen: 2 Channels1

- Position Sensors: 2 Interfaces1

- Analog I/O: 8 Inputs, 2 Outputs1

- Digital I/O: 8 Channels1

- Sensor Interfaces: 21

- Protection Rating: IP20 (though mentioned as IP67 for rugged environments in some contexts)12

- Input Voltage: AC 220V3

- Output Voltage: DC 0-10V3

- Output Current: 0-20mA3

- Control Precision: 0.1%3

- Control Method: PID Closed-Loop Control3

- Operating Temperature: -10°C to 50°C3

- Storage Temperature: -20°C to 70°C3

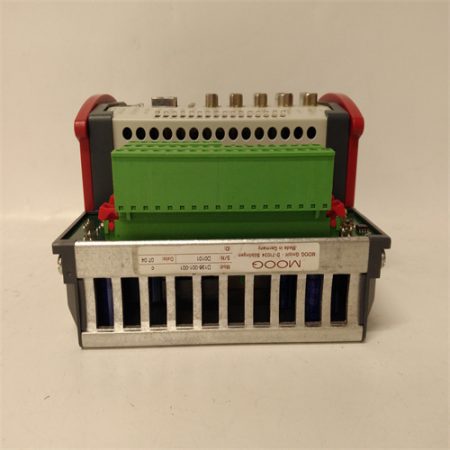

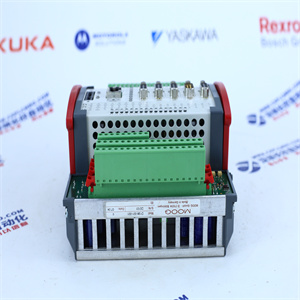

- Dimensions: 120mm × 80mm × 40mm3

- Weight: 0.5kg3

Series Information:

- Part of MOOG’s MSC I (Motion Servo Controller I) series4.

Distinct Features:

- High-Resolution Analog I/O: Enables precise control and monitoring of system parameters1.

- Modular Design: Provides flexibility in system configuration and expansion5.

- Multi-Axis Control: Capable of controlling up to 30 axes for complex motion profiles5.

- Fast Cycle Times: Loop times as low as 100 microseconds for fast control responses4.

- PLC Functionality: Integrated PLC allows for programming of control logic and sequences145.

- Ethernet, USB, CAN, and Other Bus Interfaces: Facilitates communication with other devices and systems4.

- Robust and Reliable: Designed for use in harsh industrial environments2.

Applications:

- Industrial automation and robotics45.

- Motion control systems requiring precise positioning, speed, and force control45.

- Hydraulic and electric servo drive systems5.

- Material handling and assembly machinery2.

Note: The information provided is based on the latest available data as of the search conducted. Always refer to the official MOOG documentation or datasheets for the most accurate and up-to-date specifications. Also, note that “D136-001-007.1” might be a specific variant or revision not covered directly in this response, so it’s important to confirm the exact model number with the manufacturer.

MOOG D136-001-007.1

MOOG D136-001-007.1

Reviews

There are no reviews yet.