Product Details, Parameters, Specifications, Dimensions, Weight, Series, Features, and Functions of Bently Nevada 3500_42M 176449-02 (in English):

Product Details

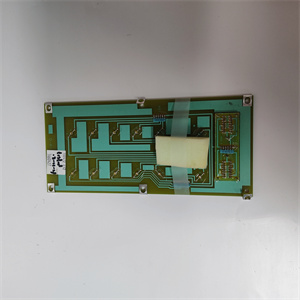

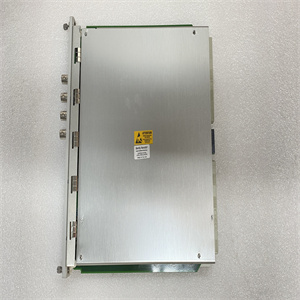

The Bently Nevada 3500_42M 176449-02 is a proximity transducer that belongs to the renowned 3500 Series of machinery protection and condition monitoring systems. This transducer is specifically designed to measure the dynamic position or vibration of rotating machinery components, such as bearings, shafts, and gears. It is widely used in critical applications where precise and reliable monitoring is essential for maintaining machinery health and preventing unexpected downtime.

BENTLY 3500_42M 176449-02

Product Parameters

- Measurement Range: The 3500_42M 176449-02 has a specified range of measurements, typically expressed in millimeters or inches, depending on the model and application. This range defines the maximum and minimum distances the transducer can accurately measure.

- Sensitivity: The transducer’s sensitivity determines its ability to detect small changes in position or vibration. High sensitivity is crucial for early detection of potential machinery issues.

- Frequency Response: The transducer is designed to accurately measure vibrations within a specific frequency range, allowing it to capture a wide range of mechanical phenomena.

- Output Signal: The transducer outputs a signal, typically a voltage or current, that is proportional to the measured position or vibration. This signal can be transmitted to a monitoring system for analysis and display.

Product Specifications

- Environmental Ratings: The 3500_42M 176449-02 is designed to withstand harsh industrial environments, with specified temperature, humidity, and vibration ratings.

- Accuracy: The transducer’s measurement accuracy is critical for reliable machinery monitoring and fault detection. Bently Nevada’s 3500 Series transducers are known for their high accuracy and repeatability.

- Compatibility: The 3500_42M 176449-02 is fully compatible with the 3500 Series monitoring systems and can be easily integrated with other Bently Nevada components and accessories.

Dimensions and Weight

- Dimensions: The exact dimensions of the 3500_42M 176449-02 will vary depending on the specific model and configuration. However, Bently Nevada typically provides detailed dimensional drawings in the product’s technical manual or specifications sheet.

- Weight: The transducer’s weight is also specified in the official documentation and is an important consideration for installation and handling.

Series

The Bently Nevada 3500_42M 176449-02 belongs to the 3500 Series of machinery protection and condition monitoring systems, a comprehensive suite of products designed to meet the demanding requirements of critical industrial applications.

Features

- High-Performance Sensing: The transducer utilizes advanced sensing technology to provide precise and reliable measurements of machinery position and vibration.

- Rugged Construction: Engineered for harsh industrial environments, the transducer features a rugged design that ensures long-term reliability and durability.

- Easy Installation and Configuration: The transducer is designed for easy installation and configuration, minimizing downtime during system upgrades or maintenance.

- Scalable and Modular: The 3500 Series is a scalable and modular system, allowing users to customize their monitoring solution to meet specific application requirements.

Functions

- Vibration Monitoring: The 3500_42M 176449-02 measures the vibration of rotating machinery components, providing valuable insights into machine health and performance.

- Position Monitoring: By measuring the dynamic position of machinery components, the transducer can help detect imbalances, misalignments, and other potential issues.

- Fault Detection and Prevention: Integrated with the 3500 Series monitoring system, the transducer provides real-time data that can be used to detect and prevent machinery faults before they lead to downtime or more serious damage.

- Condition Monitoring: As part of a comprehensive condition monitoring strategy, the transducer contributes to the overall health and performance assessment of rotating machinery.

BENTLY 3500_42M 176449-02

BENTLY 3500_42M 176449-02