1756-IF16 rockwell

The Rockwell Automation 1756-IF16 is a Flex I/O module that offers a range of capabilities and specifications tailored for industrial automation applications. Here’s an overview of its key parameters, specifications, dimensions, weight, series, features, and functions in English:

Product Overview:

Model: 1756-IF16

Manufacturer: Rockwell Automation

Product Type: Flex I/O Module

Specifications:

Input/Output Type: Analog Input

Number of Channels: 16

Input Voltage Range: Typically designed for specific analog signals (e.g., 4-20mA, 0-10V, etc.), which should be confirmed based on the exact model variant.

Resolution: Depends on the input signal range and conversion method, but generally provides high-resolution analog-to-digital conversion.

Accuracy: Specified by the manufacturer and critical for precise measurement applications.

Isolation: May offer channel-to-channel and/or channel-to-ground isolation for increased safety and signal integrity.

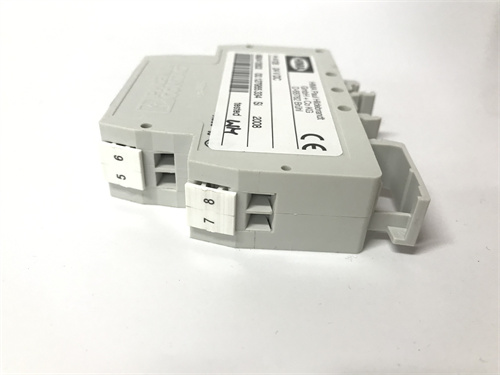

Dimensions & Weight:

Dimensions: Exact dimensions vary by model but are typically compact, designed for easy integration into industrial cabinets and racks.

Weight: Lightweight, suitable for mounting on DIN rails or in panel-mount configurations.

Series:

Belongs to the Rockwell Automation Flex I/O family of modules, which provides flexible and scalable I/O solutions for a wide range of automation tasks.

Features:

Flexibility: Allows for customization and expansion based on specific application requirements.

Scalability: Can be combined with other Flex I/O modules to create larger systems.

Integration: Seamless integration with Rockwell Automation’s control systems and software, such as ControlLogix, CompactLogix, and Studio 5000.

Diagnostics: May include built-in diagnostics to help identify and resolve issues quickly.

Rugged Design: Designed for industrial environments, withstanding harsh conditions like dust, vibration, and temperature fluctuations.

Functions:

Analog Signal Acquisition: Converts analog sensor signals (e.g., temperature, pressure, flow) into digital values that can be processed by a PLC or other control system.

Process Control: Enables precise control of industrial processes by providing real-time feedback on process variables.

Monitoring: Allows for continuous monitoring of critical process parameters, ensuring optimal operation and safety.

Please note that specific details like input voltage ranges, resolutions, and dimensions may vary depending on the exact model variant and its intended application. Always refer to the latest product documentation or contact the manufacturer for the most accurate and up-to-date information.

1756-IF16 (2)

1756-IF16 (2)