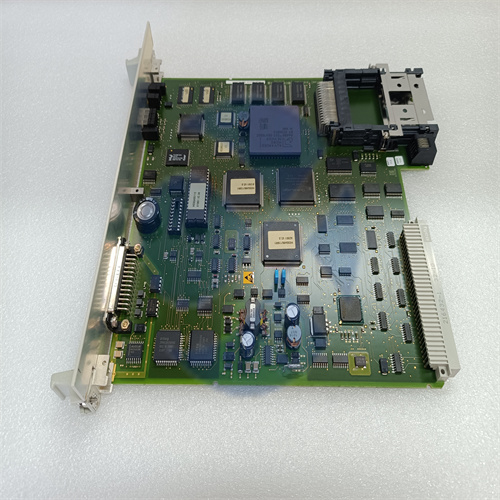

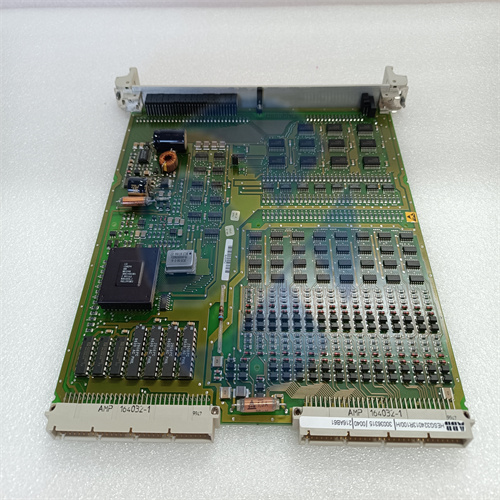

Product Description

The HC800 ABB control processor module is responsible for handling various control tasks,including data processing and calculations.

feature

Simultaneously supporting SD series I/O,Harmony Rack I/O,and S800 I/O subsystems

Perform closed-loop control of over 5000 I/O in less than 250 milliseconds.

Downloadable Firmware-Extended User Configuration Memory(NVRAM)and Real Time Memory(RAM)

Support 30000 function blocks-flexible online configuration function

Supports up to 8 segmented tasks,with each segment supporting a minimum execution cycle of 1 millisecond

Dedicated redundant peer-to-peer controller communication bus supports an update rate of less than 100 milliseconds

The HPC800 controller is based on a 256MHz,32-bit Freescale Coldfire processor,which can adapt to a wide range of applications and process requirements.Through S+engineering tool configuration,HPC800 functionality is an extensive library composed of over 150 predefined control algorithms or functional codes.These features provide the ability to easily design complex control strategies for any control application,including continuous,sequential,batch,and advanced control.In addition to standard function blocks,the HPC800 also supports C programming,batch processing,and user-defined function codes.

The HPC800 is designed to provide maximum reliability and availability with high reliability and availability.

With all levels of redundancy design such as CPU,power supply,internal bus,I/O network,communication ports,and factory network,the HPC800 controller subsystem provides the highest level of availability.Compliance with international standards ensures the highest level of reliability and quality to meet the strictest standards and requirements around the world.Together,they provide users with the benefits of fast,accurate,and uninterrupted control of process production,thereby improving production efficiency,improving availability,and reducing maintenance costs

Adopting a DIN rail shape,standard 24 VDC power input,and standard Ethernet makes installation simple and flexible.This reduces the limitations of cabinet space,size,or layout,and provides a wide range of commercial power and network peripheral device options,thereby reducing installation and maintenance costs.

The dedicated bus(CW800)used by HPC800 for peer-to-peer controller communication can achieve an update rate of less than 100 milliseconds.It is crucial for fast and accurate control,coordination between several process stages(i.e.between boilers and turbines),and the use of process points in several subsystems without adding on-site transmitters or cables.The CW800 peer-to-peer communication bus is completely redundant.

The soft controller reduces debugging time.For new factories,upgrades,or expansion projects,the SD series soft controller can thoroughly test and readjust the control circuit before on-site implementation,greatly reducing debugging and startup time and costs.The SD series soft controller uses the same control logic(i.e.functional block configuration)as the physical SD series controller.Combined with virtual communication devices,the entire SD series controlled system can be implemented on one or more PCs,allowing the test results generated in the virtual environment to be directly transferred to the operating system environment.

Comprehensive I/O support for HPC800

Simultaneously supports SD series I/O,Harmony Rack I/O,and S800 I/O subsystems,and can provide closed-loop control for 5000 I/O points in less than 250 milliseconds.This provides great flexibility and various input/output and signal conditioning functions,which combine to form the best automation solution.S+Engineering Composertool uses standard functional code to configure and maintain all HPC800 I/O modules and channels.Through the redundant I/O network HN800,each HPC800 controller can communicate with up to 64 SD series I/O modules,SD series PDP800 PROFIBUS modules,or Harmony Rack RIO22 modules.Each PDP800 can drive over 1500 S800 I/O modules through PROFIBUS DP V2,while each RIO22 module can drive 64 Harmony Rack I/O modules.All HPC800 I/O can be configured as local I/O,remote I/O,or mixed I/O.Remote I/O communicates through fiber optic expansion.Event sequences(SOEs)with a 1 millisecond timestamp resolution can be used throughout the entire system.In addition to traditional signal based I/O,the HPC800 also provides integrated turbine control through a series of dedicated turbine control modules.

These come in Harmony rack form or Symphony Plus DIN rail form,including:-Hydraulic servo module(HSS and VP800)-Turbine protection module(TPS and TP800)-Turbine automatic synchronization module(TAS and AS800)-Condition monitoring module(CMM and MCM800)-Intelligent HART I/OHPC800 controller seamlessly integrates with the HART field device module through HAI805 and HAO805 HART.This provides access to a wide range of intelligent field devices,including transmitters and actuators from other ABBand suppliers.In addition to the 4-20 mA primary variable,the function code control application in the HPC800 controller can also access all secondary,tertiary,and quaternary variables in the HART device.Due to the separate HART modem design for each channel of the module,real-time use of this data is feasible.Data can be calculated and used as part of control strategies,as well as displayed and alarmed on the S+operation console.

The HPC800 HART function allows users to fully utilize their investment in HART instruments.Due to the limitations of receiving device information in I/O systems,intelligent devices are often underestimated.For SD series HART modules,adding secondary variables to the control strategy can reduce the total number of required field devices and I/O channels.The visibility of HART diagnostic data at the system level reduces maintenance costs by proactively responding to the degradation of on-site device performance before a fault occurs.

application area

The HC800 ABB control processor module is widely used in industrial automation control systems,such as manufacturing,oil,and natural gas industries.

Reviews

There are no reviews yet.