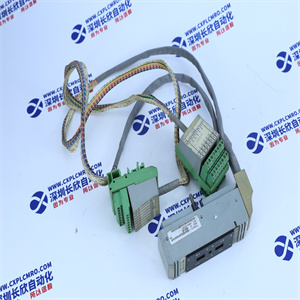

FOXBORO FBM231

FOXBORO FBM231 is a remote I/O device used for real-time data collection and transmission.The following are the main parameters and applications of the product:

Product parameters:

Input/output types:digital input,digital output,analog input,analog output

Data transmission method:transmit data through RS-485 or fiber optic cable

Communication protocol:Supports Modbus communication protocol

Working temperature range:-40°C to 85°C

Protection level:IP67 protection level,suitable for harsh industrial environments

Power supply:24V DC power supply

Product application:

Industrial automation control system:FBM231 can be used for real-time monitoring and control of industrial equipment,such as valves,pump stations,and sensors.

Data collection and transmission:FBM231 can collect on-site data and transmit it to a remote server through a communication network,achieving remote monitoring and management of data.

Power system monitoring:FBM231 can be applied to power system monitoring,real-time collection of current,voltage and other data,for power grid status monitoring and fault diagnosis.

Environmental monitoring:FBM231 can connect various environmental sensors,such as temperature and humidity sensors,gas sensors,etc.,for environmental data monitoring and management.

The Foxboro FBM231 is a fieldbus module designed for use in industrial automation systems.It is part of the Foxboro I/A Series system and is used for communication between field devices and control systems.

The FBM231 module supports the Foundation Fieldbus protocol,which is a digital communication standard used in process control systems.It allows for the transmission of data between field devices such as sensors,actuators,and controllers.

The FBM231 module features a compact design and can be easily installed in a field enclosure.It has multiple communication ports for connecting to field devices and control systems.It also has built-in diagnostics and fault detection capabilities,allowing for easy troubleshooting and maintenance.

The FBM231 module is highly reliable and can operate in harsh industrial environments.It is designed to withstand extreme temperatures,humidity,and vibration.It also has built-in protection against electrical interference and power surges.

Allen Bradley 1785-L80C15/F WITH 1785-ENET/A Used

Reliance Drive Interface Part#770.91.20 Used

Indramat Servo Motor Part#MDD112C-N-030-N2M-130GB1Used

Allen Bradley Ind.Computer Cat#6181-CHDCBBZZR Used

Allen Bradley Ind.Computer Cat#6181-CHBCBBZZR Used

Allen Bradley Servo Drive Cat#1394C-SJT05-L Used Nice

Magnetek Drive 75HP Drive GPD515C-B096 Used

Allen Bradley AC Drive Cat#1336-B050-E0G-FA2-L3 Used

Allen Bradley Servo Motor Gear Box MPG-A004-031M22 NIB

The FOXBORO FBM231 is a distributed I/O module used in industrial automation systems.It is designed to communicate with a control system through a network connection and offers various functionalities for monitoring and controlling field devices.

The content of the product information materials for the FOXBORO FBM231 typically includes:

1.Product Overview:An introduction to the module,its purpose,and the benefits it offers in industrial applications.

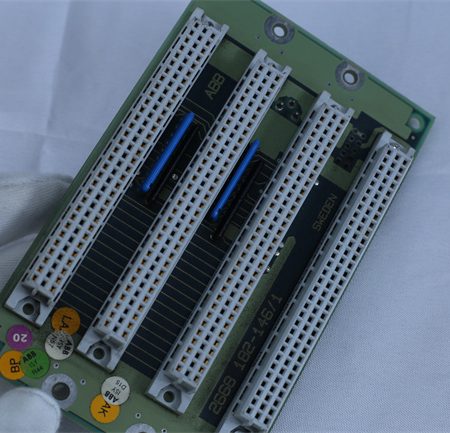

2.Features and Specifications:A detailed list of the module’s technical specifications,including its physical dimensions,weight,power requirements,and operating conditions.It may also include information about its communication interfaces,network protocols,and compatibility with other system components.

3.Functionality:An explanation of the different features and capabilities of the FBM231 module.This may include details about its input/output channels,communication protocols,support for various field devices,and built-in diagnostics.

4.Installation and Configuration:Step-by-step instructions on how to install and set up the FBM231 module in an industrial control system.This may include information about mounting options,wiring guidelines,and network configuration.

5.Programming and Integration:Guidance on how to integrate the FBM231 module into a control system,including programming examples and code snippets to communicate with the module and retrieve data from connected field devices.

6.Troubleshooting and Maintenance:Tips and techniques for identifying and resolving common issues that may arise during installation,configuration,or operation of the FBM231.It may also include guidelines for routine maintenance,firmware updates,and troubleshooting procedures.

7.Safety and Compliance:Information regarding safety precautions,regulatory compliance,and certifications that the FBM231 module adheres to.

Additionally,the parameters mentioned in the product information materials may include:

-Input/Output Channel Count:The number of analog or digital input/output channels provided by the FBM231 module.

-Measurement Range:The range of values that can be measured or controlled by each input/output channel.

-Communication Protocols:The supported network protocols or standards for interfacing with the module,such as Modbus,PROFIBUS,or EtherNet/IP.

-Input/Output Types:The types of signals that can be received or transmitted by the module,such as voltage,current,resistance,or digital.

-Operating Temperature:The range of temperatures within which the module can operate without any adverse effects.

-Power Supply:The voltage range required to power the module.

-Data Update Rate:The frequency at which the module updates its input/output data.

Reviews

There are no reviews yet.