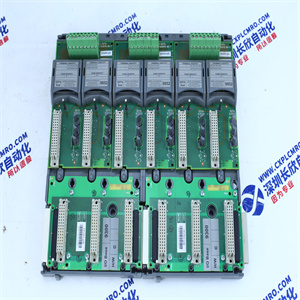

ICS TRIPLEX 9300

The ICS TRIPLEX 9300 is a safety instrumented system (SIS) designed to provide high integrity safety protection for critical processes in the oil and gas, chemical, and power industries. It is a modular system that consists of a range of components, including controllers, input/output modules, power supplies, and communication modules.

The 9300 system is designed to meet the requirements of international safety standards, including IEC 61508 and IEC 61511, and is capable of SIL 3 safety integrity levels. It is also designed to be highly reliable, with redundant components and fault-tolerant architecture.

The system is configurable using TRISTATION 1131 software, which allows for easy programming and configuration of the system. It also features advanced diagnostic capabilities, including online monitoring and fault detection, to ensure that the system is always operating at peak performance.

Overall, the ICS TRIPLEX 9300 is a highly advanced and reliable safety instrumented system that provides critical protection for industrial processes.

Agilent/HP 83540A RF Plug In 2-8.4 GHz

Agilent/HP 70902A IF Section 10 Hz to 300 kHz Module

Agilent 70310A Precision Frequency Reference Module

Agilent/HP 4396B RF Network/Spectrum Analyzer

Tektronix TDS520C Digitizing Oscilloscope 500MHz,1GS/s

Agilent/HP 1670D Benchtop Logic Analyzer w/Deep Mem.

Agilent 4142B Modular DC Source/Monitor Mainframe

The ICS Triplex 9300 is a high-performance, robust and reliable instrument and control system designed for process automation and safety applications in hazardous environments. It is commonly used in industries such as oil and gas, petrochemical, power generation, and chemical.

Here are some key features and parameters of the ICS Triplex 9300:

- Redundancy: The 9300 system incorporates triple modular redundancy (TMR) technology, which provides a high level of fault tolerance and ensures continuous operation even in the event of component failures.

- Safety Integrity Level (SIL) Certification: The system is SIL 3 certified, meeting the highest safety standards recognized in the industry.

- Process Automation: The 9300 can handle complex control functions and offers advanced programming capabilities, making it suitable for a wide range of process automation applications.

- HART Compatibility: The system supports HART (Highway Addressable Remote Transducer) communication protocol, allowing seamless integration with HART-enabled field devices.

- Communication Interfaces: It provides various communication interfaces, including Ethernet, Modbus TCP/IP, OPC, and RS485, enabling connectivity with other control systems and devices.

- Flexibility and Scalability: The 9300 is a flexible and scalable system, allowing expansion and customization based on specific project requirements.

- Diagnostic and Monitoring Capabilities: The system includes built-in diagnostic and monitoring features, facilitating proactive maintenance and troubleshooting.

- Human-Machine Interface (HMI): The 9300 is typically equipped with a user-friendly HMI, providing operators with intuitive control and monitoring capabilities.

- Environmental Protection: The system is designed to operate in harsh and hazardous environments, with features such as rugged enclosures, explosion-proof certifications, and wide operating temperature ranges.

- Remote Monitoring and Control: The 9300 supports remote monitoring and control, enabling real-time data access and control from a central control room or remote locations.

Reviews

There are no reviews yet.