The following is a detailed description of the relevant information about ABB TK850V007 and PLC(Programmable Logic Controller):

1.Overview of ABB TK850V007

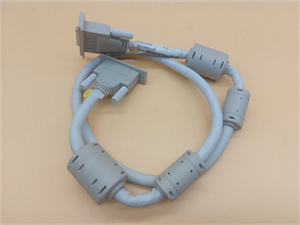

TK850V007 is a product number under the ABB brand,which may represent a specific part or component.According to publicly released information,TK850V007 is mentioned as a CEX bus extension cable,which is a cable used to connect PLC or other automation equipment.However,the specific association between TK850V007 and PLC2 is not directly mentioned in the reference information provided.

2.Overview of PLC

PLC is a digital computing and operating electronic system designed specifically for use in industrial environments.It uses a type of programmable memory to store instructions for performing operations such as logic operations,sequential control,timing,counting and arithmetic operations,and controls various types of mechanical equipment or production processes through digital or analoginput/output.、

3.Main features of PLC

High reliability and strong anti-interference ability:PLC adopts modern large-scale integrated circuit technology,is manufactured with strict production processes,and the internal circuit adopts advanced anti-interference technology,which has high reliability.In addition,PLC has a hardware fault self-detection function,which can issue alarm information in time when a fault occurs.In the application software,the user can also program the fault self-diagnosis program of the peripheral device,so that the circuits and equipment in the system other than PLC can also obtain fault self-diagnosis protection.

Perfect functions and wide application:PLC has developed to this day and has formed a series of products of various sizes,large,medium and small.It can be used in industrial control occasions of various sizes.In addition to the logic processing function,most modern PLCs have perfect data computing capabilities and can be used in various digital control fields.In recent years,a large number of PLC functional units have emerged,allowing PLC to penetrate into various industrial controls such as position control,temperature control,and CNC.Coupled with the enhancement of PLC communication capabilities and the development of human-machine interface technology,it has become very easy to use PLC to form various control systems.

Easy to learn and use,it is popular among engineering and technical personnel:PLC,as a general industrial control computer,is an industrial control equipment for industrial and mining enterprises.It has an easy interface and its programming language is easily accepted by the majority of engineering and technical personnel.The graphic symbols and expressions of the ladder diagram language are similar to those of the relay circuit diagram.Only a small amount of switch logic control instructions of the PLC can be used to easily realize the functions of the relay circuit.It opens the door for people who are not familiar with electronic circuits,computer principles and assembly languagesto engage in industrial control.

The system has a short design and construction cycle and is easy to maintain:when the production process needs to be changed or the production equipment needs to be updated,the old equipment can be transformed with PLC.There is no need to change the hardware wiring or the original program.Only some parameters in the program need to be changed,and even these parameters can be modified online.

Small size,light weight,and low energy consumption:Taking the ultra-small PLC as an example,the bottom size of the recently launched variety is less than 100mm,the weight is less than 150g,and the power consumption is only a few watts.Due to its small size,it is easy to be installed inside the machine,and it is an ideal control device for realizing mechatronics.

4.Application fields of PLC

PLC has been widely used in various industries such as steel,petroleum,chemical industry,electricity,building materials,machinery manufacturing,automobile,textile,transportation,environmental protection and culture and entertainment.The usage can be roughly divided into the following categories:

Switch quantity logic control:replace the traditional relay circuit to realize logic control and sequential control.It can be used for the control of single equipment,multi-machine group control and automated production line.Such as injection molding machine,printing machine,bookbinding machine,modular machine tool,grinder,packaging production line,electroplating assembly line,etc.

Industrial process control:In the industrial production process,there are some continuously changing physical quantities such as temperature,pressure,flow,liquid level and speed.PLC uses corresponding A/D and D/A conversion modules and various control algorithm programs to process analog quantities and complete closed-loop control.PID adjustment is a commonly used adjustment method in general closed-loop control systems.Large and medium-sized PLCs have PID modules,and many small PLCs currently also have this function module.PID processing generally runs a dedicated PID subroutine.

Motion control:PLC can be used for circular motion or linear motion control.In terms of control mechanism configuration,in the early days,it was mainly used for switching I/O modules to connect position sensors and actuators.Now,dedicated motion control modules are generally used.For example,single-axis or multi-axis position control modules that can drive stepper motors or servo motors.Almost all products of major PLC manufacturers in the world have motion control functions and are widely used in various machinery,machine tools,robots,elevators and other occasions.

Data processing:Modern PLC has functions such as mathematical operations(including matrix operations,function operations,logical operations),data conversion,data transmission,sorting,table lookup,bit operations,etc.,which can complete data collection,analysis and processing.These data can be compared with reference valuesstored in the memory to complete certain control operations,or they can be transmitted to other intelligent devices using communication functions,or printed and tabulated.Data processing is generally used in large control systems,such as unmanned flexible manufacturing systems;it can also be used in process control systems,such as some large control systems in papermaking,metallurgy,and food industries.

Communication and networking:PLC communication includes communication between PLCs and communication between PLCs and other intelligent devices.With the development of computer communication technology,the communication and networking functions of PLCs are becoming more and more perfect.PLC communication is now mainly divided into the following categories:

Communication between PLCs:communication between PLCs and communication between PLCs and upper computers.Serial communication is generally used.Serial communication is mostly used for point-to-point and point-to-multipoint communication.In addition to ordinary RS-232,RS-422(RS-485),there are also IEEE802.4,IEEE802.5(Token Bus,Token Ring)and MAP networks.

Communication between PLC and other intelligent devices:PLC can communicate with intelligent instruments,intelligent execution devices(such as inverters),etc.Communication with intelligent instruments is mainly for PLC to collect data from each instrument and process it;communication with intelligent execution devices is mainly for PLC to send control commands to the execution device.

The company mainly imports PLC modules,programmable controllers,servo control systems and DCS spare parts,such as:ABB,AB(Rockwell),GE(General Electric),Bentley,Honeywell Er),Emerson.),Motorola,Invensys,Westinghouse,etc.The company has established close cooperative relations with many world-renowned PLC and DCS product maintenance service providers.We can purchase goods directly from abroad and provide equipment and spare parts from different countries and manufacturers.

We supply goods directly from abroad,without intermediaries,reducing the cost of use.

There is really no medium that can make a difference!!

Shenzhen Changxin Automation-sufficient supply,large spot quantity,guaranteed quality,you can buy with confidence and use with peace of mind~!

If you have any defects or needs for imported PLC and DCS spare parts,please contact our team,we will help you find reliable and high-quality products super quickly,while shortening delivery time to ensure that your equipment can operate normally in the right environment.Just in time.

Professionally provide:PLC programmable control system,distributed control system(DCS),safety instrument system(SIS),ESD system,vibration monitoring system,turbo compressor unit control system(CCS)and other PLC modules,various industrial control systems,system modules,CPU,IO module,DO module,AI module,DI module,network communication module,Ethernet module,motion controller,analog input module,analog output module,digital input module,digital output module,module redundancy,power module,relay output unit,relay input unit,processor unit.

Products are widely used in:electricity,petroleum,mine hoisting,ports,heating,gas,water supply,sewage treatment,metallurgy,papermaking,textile,chemical industry,water conservancy and other modern industrial fields!

1.”Power plant DCS monitoring system”

2.”Intelligent flat tempering furnace system manufacturing”

3.”PLC programmable transmission control system”

4.”DCS distributed control system”

5.”Intelligent fire water suppl

Reviews

There are no reviews yet.