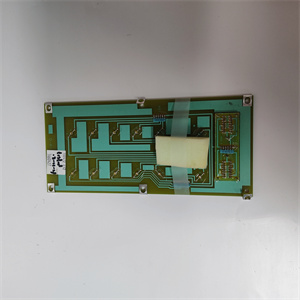

350042M 140734-02

Sure, here is the information I found on the Bently Nevada 3500/42M-01-00 140734-02 Vibration Monitor:

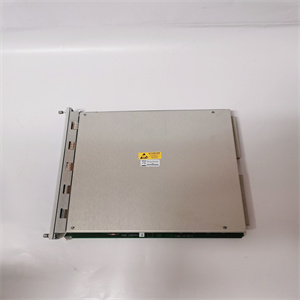

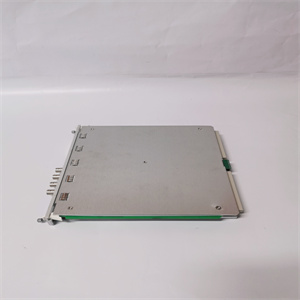

Product Name: Bently Nevada 3500/42M-01-00 140734-02 Vibration Monitor

Manufacturer: Bently Nevada

Product Type: Vibration Monitor

Product Description:

The Bently Nevada 3500/42M-01-00 140734-02 Vibration Monitor is an advanced component of the Bently Nevada 3500 Machinery Protection System. It serves as a comprehensive vibration monitoring device, enabling the detection, analysis, and protection of critical rotating machinery from vibration-related faults.

Key Features:

- High-Speed Data Acquisition: Captures vibration data at high rates (up to 10 kHz) to capture even transient events

- Advanced Spectral Analysis: Performs detailed spectral analysis to identify and diagnose specific vibration patterns associated with machinery faults

- Multiple Alarm Levels: Provides multiple alarm levels to alert operators of potential machinery issues at various severity stages

- Data Logging and Trending: Records and trends vibration data over time to identify trends and predict potential failures

- User-Friendly Interface: Offers an intuitive interface for easy configuration, monitoring, and analysis

- Rugged Construction: Withstands harsh industrial environments

-

350042M 140734-02

Specifications:

- Data Acquisition Rate: Up to 10 kHz

- Frequency Range: 2 Hz to 20 kHz

- Signal Resolution: 16 bits

- Number of Channels: 4

- Alarm Levels: 3 configurable alarm levels

- Data Logging and Trending: Stores and trends vibration data for up to 1 year

- Communication Interfaces: RS-232, RS-485, Ethernet

- Power Supply: 24 VDC

- Operating Temperature: -40°C to +70°C (-40°F to +158°F)

- Protection Rating: IP66

- Dimensions: Approximately 203 x 203 x 89 mm (8 x 8 x 3.5 in)

- Weight: Approximately 2.3 kg (5.1 lb)

Applications:

- Continuous Machinery Monitoring: Continuously monitors vibration levels and trends to detect early signs of machinery faults

- Fault Detection and Diagnosis: Identifies and diagnoses specific vibration patterns associated with various machinery faults, such as unbalance, misalignment, and bearing wear

- Predictive Maintenance: Enables predictive maintenance practices by identifying potential failures before they occur, preventing unplanned downtime and costly repairs

- Root Cause Analysis: Provides insights into the root causes of machinery faults, facilitating corrective actions to prevent recurrence

Overall, the Bently Nevada 3500/42M-01-00 140734-02 Vibration Monitor plays a vital role in the Bently Nevada 3500 Machinery Protection System, offering comprehensive vibration monitoring capabilities for enhancing machinery reliability, safety, and operational efficiency.

Please note that the specific applications and functionalities of the vibration monitor may vary depending on the overall system configuration and the specific machinery being monitored.

Here are some additional details about the Bently Nevada 3500/42M-01-00 140734-02 Vibration Monitor:

- Series: Bently Nevada 3500/42M Series

- Features:

- Advanced Phase Tracking: Accurately tracks machinery phase relationships to identify and diagnose specific fault types

- Multi-Point Monitoring: Supports monitoring of multiple machinery points simultaneously for comprehensive protection

- Scalable Architecture: Adapts to varying machinery monitoring needs by accommodating additional modules

- Safety Certifications: Meets industry safety standards for hazardous environments

Function:

The Bently Nevada 3500/42M-01-00 140734-02 Vibration Monitor serves as a crucial component within the Bently Nevada 3500 Machinery Protection System. It effectively collects, analyzes, and interprets vibration data from critical rotating machinery, enabling operators to:

- Detect Early Signs of Faults: Identify potential machinery issues early on, preventing catastrophic failures and costly downtime

- Diagnose Faults Accurately: Determine the root causes of machinery faults, allowing for targeted maintenance and repairs

- Implement Predictive Maintenance: Schedule maintenance proactively based on vibration data trends, optimizing resource allocation and preventing unplanned downtime

- Enhance Machinery Reliability: Prolong machinery lifespan and reduce maintenance costs by ensuring optimal operating conditions

- Improve Safety: Minimize safety risks associated with machinery malfunctions and failures

In summary, the Bently Nevada

350042M 140734-02