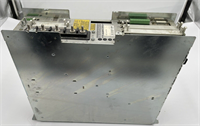

Description

The FOXBORO FBM216B P0927AJ is a redundant HART communication input module manufactured by Foxboro, designed for industrial automation and process control systems. This module provides eight independently isolated analog input channels, supporting the simultaneous processing of 4-20mA analog signals and HART digital signals, enabling bidirectional data transmission between field intelligent devices and the control system. The module features a redundant design, typically used in pairs, ensuring stable system operation even in the event of a single module failure, making it suitable for harsh industrial environments such as those found in the oil, power, and chemical industries.

Application Scenarios

In the distillation column control system of a large oil refinery, the FOXBORO FBM216B P0927AJ module is deployed to monitor critical process parameters. The refinery has multiple distillation columns, each requiring real-time monitoring of eight key parameters such as temperature, pressure, flow rate, and liquid level, totaling 64 analog signal points. Previously, the plant used traditional analog acquisition modules, which suffered from severe signal interference and frequent maintenance issues, resulting in 2-3 signal anomalies per month, leading to process fluctuations and unstable product quality.

After adopting the FBM216B P0927AJ module, the refinery achieved significant improvements. The module’s 8-channel design reduced the number of I/O modules by 60%, simplifying control cabinet wiring. HART protocol support enabled maintenance personnel to remotely read and configure field instrument parameters without requiring system downtime for on-site debugging. The module’s 600VAC electrical isolation effectively eliminated ground loops and electromagnetic interference, improving signal acquisition accuracy from ±0.2% to ±0.075%. After one year of operation, the refinery reported a 90% reduction in signal-related failures, a 40% decrease in maintenance costs, significantly improved process stability, and a 2.5% increase in product pass rate. Parameters

Main Parameters

Value/Description

Product Model

FBM216B P0927AJ

Manufacturer

FOXBORO

Product Category

Redundant HART Communication Input Module

Input Channels

8 independently isolated channels

Supported Signal Types

4-20mA analog signal + HART FSK digital signal

Input Resistance

Approximately 302Ω with internal power supply, approximately 282Ω with external power supply

Measurement Accuracy

±0.075% of full scale

Resolution

15-bit

Update Rate

Approximately 100 milliseconds per channel

Communication Rate

Approximately 2 HART messages/second

Electrical Isolation

600VAC (between channels and to ground)

Power Supply

24V DC ±5%, maximum power consumption approximately 7 watts

Operating Temperature

-20°C to +70°C

Humidity Range

5% to 95% (non-condensing)

Communication Interface

Redundant 2Mbps HDLC fieldbus

Isolation Type

Optical and transformer isolation

Enclosure Rating

G3 (harsh environment)

Mounting

DIN rail or rack mounting

Terminal Component

PVC material, -20°C to +50°C

Certifications

Complies with ISA standard S71.04

Technical Principles and Innovative Values

Innovation Point 1: Bidirectional HART Communication and Synchronous Analog Signal Processing

The core innovation of the FBM216B P0927AJ module lies in its ability to simultaneously process 4-20mA analog signals and HART digital signals, achieving true bidirectional communication. Each channel is equipped with an independent FSK modem, supporting the transmission of HART protocol frequency-shift keying signals superimposed on the analog signal. This design allows the control system to not only acquire analog values but also read and write digital parameters of HART field devices, such as device status, diagnostic information, and configuration parameters. The module can request and receive two digital messages per second from each field device, supporting HART universal commands, common practice commands, and device-specific commands, but not burst communication mode. This capability is particularly important in process control, for example, in oil refining processes, where the range and alarm points of pressure transmitters can be configured remotely without shutting down the system for on-site adjustments, significantly improving production efficiency and equipment availability. Innovation Point 2: High-Precision Sigma-Delta Conversion Technology

The module utilizes advanced Sigma-Delta (∑-Δ) data conversion technology, providing a new analog input value for each channel every 100 milliseconds, achieving 15-bit high-resolution measurement. The Sigma-Delta converter converts analog signals into high-precision digital data through oversampling and digital filtering techniques, achieving a measurement accuracy of ±0.075% of full scale. This conversion technology boasts excellent noise immunity and linearity, making it particularly suitable for industrial environments with strong electromagnetic interference. For example, in water treatment systems in the power industry, the module can accurately measure key water quality parameters such as pH, turbidity, and residual chlorine concentration, ensuring that the treatment process meets environmental standards. High-precision measurement also reduces the calibration frequency, extending it from quarterly to annually, thus lowering maintenance costs.

Innovation Point 3: Redundant Fault-Tolerant Architecture Design

The FBM216B P0927AJ uses a module-level redundancy design, providing system redundancy at the Fieldbus Module (FBM) level. Two modules are used in combination, one as the master module and the other as the tracker, with field inputs connected to a common terminal component. When the master module fails, the tracker module automatically takes over the control function, ensuring continuous system operation. This redundant architecture is crucial in critical process control, such as in GMP environments for pharmaceutical production, where any system interruption could lead to the scrapping of an entire batch of products. The module’s redundant design also supports hot-swapping, allowing for the replacement of faulty modules without system downtime, minimizing production losses. Furthermore, the modules communicate via a redundant 2Mbps HDLC fieldbus, ensuring reliable data transmission.

Innovation Point 4: Comprehensive Electrical Isolation and Interference Immunity

The module features comprehensive isolation protection in its electrical design, with 600VAC current isolation (optical and transformer isolation) between each input channel, between channels and the module’s logic circuit, and between channels and ground. This isolation design effectively prevents ground loops, common-mode voltages, and electromagnetic interference from affecting the signal, ensuring signal stability and accuracy in harsh industrial environments. The module also possesses a high common-mode rejection ratio (CMRR), capable of suppressing electrical noise commonly found in industrial settings, such as that generated by motor starting and variable frequency drives. In chemical plants, the module can reliably acquire critical parameters such as temperature and pressure, maintaining reliable performance even in environments with highly corrosive gases and high temperatures and pressures. The module’s robust extruded aluminum housing design meets the G3 harsh environment standard and is suitable for operating temperatures ranging from -20°C to +70°C.

Application Cases and Industry Value

Case Study: Petrochemical Distillation Column Control System

A large petrochemical company deployed the FBM216B P0927AJ module in the distillation column control system of its ethylene plant. The plant has eight distillation columns, each requiring monitoring of critical parameters such as top temperature, bottom temperature, feed flow rate, reflux ratio, and column pressure, totaling 64 analog signal points. Previously, the factory used traditional analog acquisition cards, which suffered from signal drift and poor anti-interference capabilities, leading to frequent fluctuations in process parameters and unstable product yield.

After adopting the FBM216B P0927AJ module, the system achieved significant improvements. The module’s 8-channel design reduced the number of I/O modules from 16 to 8, increasing control cabinet space utilization by 50%. HART protocol support allows maintenance personnel to remotely read and configure field instrument parameters without shutting down the system for on-site debugging, reducing maintenance time from an average of 4 hours per instance to 30 minutes per instance. The module’s 600VAC electrical isolation effectively eliminated ground loops and electromagnetic interference, improving signal acquisition accuracy from ±0.2% to ±0.075%, and significantly enhancing process parameter stability. After one year of operation, the factory reported a 90% reduction in signal-related failures, a 40% decrease in maintenance costs, and a 1.2% increase in ethylene product yield, resulting in an estimated annual benefit of approximately 8 million RMB.

Case Study: Thermal Power Plant Boiler Control System

A 600MW thermal power plant applied the FBM216B P0927AJ module in its boiler control system to monitor critical parameters such as boiler drum water level, main steam temperature, main steam pressure, and feedwater flow rate. Boiler control is the core control loop of the power plant, and any signal anomaly can lead to boiler tripping, causing significant economic losses. Previously, the power plant used conventional analog input modules, which suffered from insufficient signal interference immunity and frequent maintenance issues, resulting in approximately 2-3 unplanned shutdowns annually due to signal failures.

After adopting the FBM216B P0927AJ module, system reliability significantly improved. The module’s redundant design ensures that a single module failure does not affect system operation, and the hot-swapping function allows for the replacement of faulty modules without shutting down the system. HART protocol support enables the power plant to remotely diagnose the status of field instruments, detect potential faults in advance, and increase the proportion of preventive maintenance from 30% to 70%. The module’s high-precision measurement and anti-interference capabilities ensure the stability of the boiler control loop, improving the main steam temperature control accuracy from ±3°C to ±1°C, and increasing boiler efficiency by 0.5%. After two years of operation, the power plant achieved zero unplanned shutdowns, resulting in an annual increase in power generation of approximately 12 million kilowatt-hours, demonstrating significant economic benefits.

Related Product Combination Solutions

The FOXBORO FBM211 is a 16-channel 0-20mA analog input module, offering higher channel density, suitable for applications requiring a large number of analog signal acquisitions. Compared to the FBM216B P0927AJ, the FBM211 does not support HART communication, but the number of channels is doubled, making it suitable for pure analog signal acquisition applications that do not require HART functionality.

The FOXBORO FBM212 is a 14-channel thermocouple input module, specifically designed for temperature measurement applications. This module supports various thermocouple types (K, J, T, E, S, R, B, etc.), provides cold junction compensation and linearization processing, and is suitable for high-temperature measurement applications. It can be used in conjunction with the FBM216B P0927AJ in systems that require simultaneous acquisition of analog and temperature signals.

The FOXBORO FBM213 is an 8-channel resistance temperature detector (RTD) input module, supporting 2-wire and 3-wire RTD sensors such as nickel, platinum, and copper resistors. This module provides high-precision temperature measurement and is suitable for chemical, pharmaceutical, and other industries requiring precise temperature control. It can be combined with the FBM216B P0927AJ to build a complete temperature, pressure, and flow monitoring system. The FOXBORO FBM201 is an 8-channel 0-20mA analog input module, a basic version of the FBM216B P0927AJ, and does not support HART communication. This module is suitable for cost-sensitive applications requiring simple analog signal acquisition without HART functionality.

The FOXBORO FBM202 is an 8-channel thermocouple input module, similar to the FBM212 but with fewer channels, suitable for small to medium-scale temperature measurement systems. This module can be used in conjunction with the FBM216B P0927AJ to achieve comprehensive acquisition of multiple signal types.

The FOXBORO FBM203 is an 8-channel RTD input module, similar to the FBM213 but with fewer channels, suitable for small to medium-scale temperature measurement systems. This module can be used with the FBM216B P0927AJ to build a complete temperature, pressure, and flow monitoring system.

The FOXBORO FBM204 is a 4-channel 0-20mA analog input + 4-channel 0-20mA analog output module, providing an integrated input/output solution. This module is suitable for applications requiring simultaneous signal acquisition and control of actuators, and can be used with the FBM216B P0927AJ to expand system functionality.

The FOXBORO FBM205 is a redundant 4-channel 0-20mA analog input + 4-channel 0-20mA analog output module, providing a highly reliable input/output solution. This module is suitable for critical control loops and can be used with the FBM216B P0927AJ to build a highly reliable control system.

The FOXBORO FBM206 is an 8-channel 0-12.5kHz frequency input module, specifically designed for frequency signal acquisition, such as speed and flow pulse signals. This module can be used with the FBM216B P0927AJ to achieve comprehensive acquisition of various signal types.

The FOXBORO FBM237 is an 8-channel 0-20mA analog output module, used to control actuators such as control valves and variable frequency drives. This module can be used with the FBM216B P0927AJ to build a complete closed-loop control system. Installation, Maintenance, and Full-Cycle Support

Installation Requirements

The FBM216B P0927AJ module supports DIN rail or rack mounting. Before installation, ensure the control cabinet environment meets the following conditions: ambient temperature -20°C to +70°C, relative humidity 5% to 95% (non-condensing), power supply voltage 24V DC ±5%, and grounding resistance less than 5Ω. The module should be installed in a G3 (harsh) environment enclosure compliant with ISA standard S71.04, ensuring sufficient ventilation space to prevent heat accumulation. Field wiring is connected to the module via terminal assemblies (TA), which support local or remote connection methods, selectable according to field wiring requirements. Each channel can be configured for internal or external power supply. When using external power, a cable balance-unbalance-unbalance transformer module is required to prevent channel crosstalk.

Routine maintenance mainly includes regular inspections.