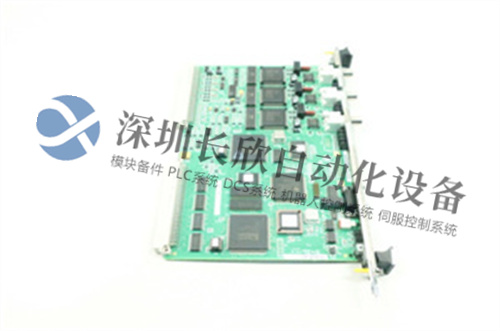

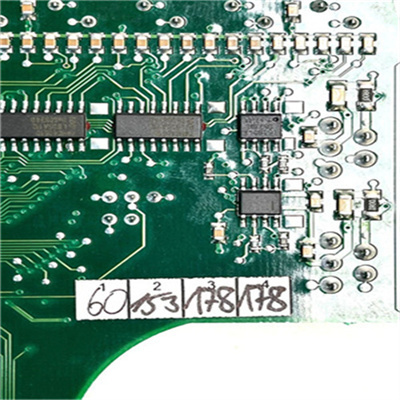

GE IS220PAICH1B

GE IS220PAICH1B Product Details

Product Overview

GE IS220PAICH1B is an analog input/output module in the General Electric(GE)Mark VIe series control system.It is mainly used to connect analog sensors(such as pressure sensors,temperature sensors,etc.)and actuators,convert analog signals into digital signals,and process them in the control system.

Main Functions

Analog Signal Input:Can handle up to 10 analog input signals,including 5V or 10V voltage input and 0-20mA current loop input.

Analog Signal Output:Can convert digital signals into analog signals for controlling actuators.

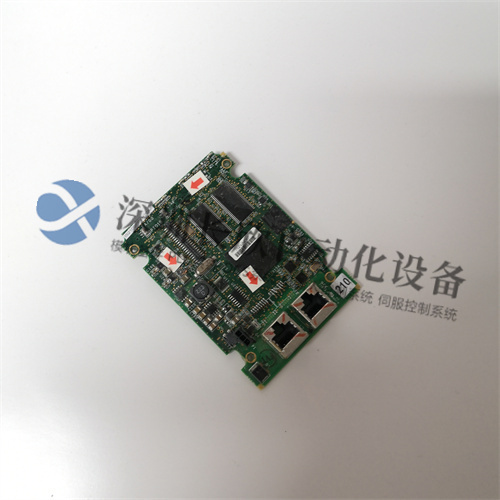

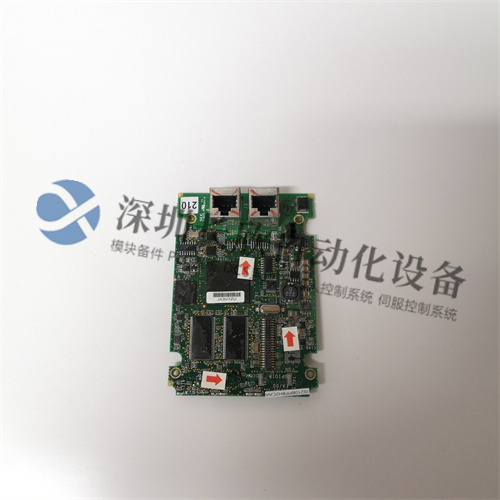

Ethernet Communication:Communicates with the Mark VIe controller via dual 100MB full-duplex Ethernet ports.

Flexible Configuration:Can be flexibly configured according to different application requirements,such as input type,range,filtering,etc.

Product Features

High Reliability:Suitable for industrial environments,with high stability and reliability.

Modular Design:Convenient installation and maintenance.

Flexible Configuration:Can be configured according to different application requirements.

Dual Ethernet Ports:Provides redundant and high-bandwidth communication.

Application scenarios

Mark VIe control system:Mainly used in GE’s Mark VIe series control systems to collect process variables and control actuators.

Industrial automation:Widely used in industrial automation fields such as power plants and petrochemical plants.