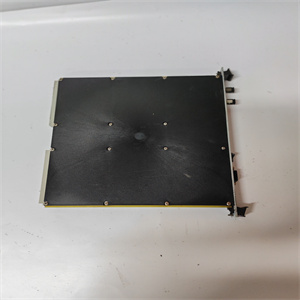

9199-00002 A6120

9199-00002 A6120

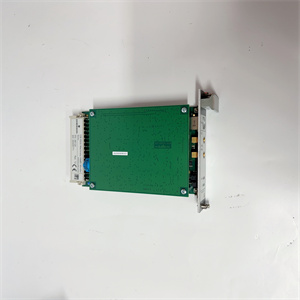

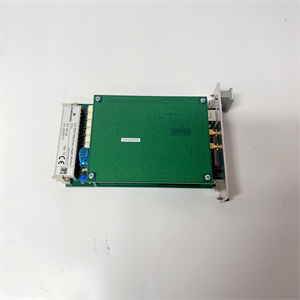

The Emerson A6120 9199-00002 Vibration Monitoring Module is a crucial component of machinery protection systems, designed to monitor the health of rotating equipment and detect potential faults or imbalances that could lead to costly breakdowns. It effectively captures vibration data, analyzes it for abnormalities, and provides alarms or warnings to prevent catastrophic failures.

Parameters:

- Vibration Measurement: Measures vibration levels in three axes (vertical, horizontal, and axial)

- Frequency Range: 10 Hz to 10 kHz

- Sensitivity: 0.001 g/rms

- Accuracy: ±2 dB

- Data Acquisition Rate: Up to 10 kHz

- Data Storage: Stores vibration data internally for up to 500 events

- Communication: RS-485 Modbus communication

- Power Supply: 24 VDC

- Power Consumption: Approximately 10 W

- Operating Temperature: -40°C to +70°C (-40°F to +158°F)

- Storage Temperature: -40°C to +85°C (-40°F to +185°F)

- Humidity: 5% to 95% RH non-condensing

- Vibration: 0.5 g RMS, 5 to 500 Hz

- Shock: 5 g, 22 ms half-sine pulse

- EMC: Meets IEC 61000-4-2, IEC 61000-4-3, and IEC 61000-4-6 standards

- Safety: Meets UL 508, CSA C22.2 No. 142, and CE standards

Specifications:

- Vibration Monitoring Module: Monitors vibration levels in rotating machinery to detect potential faults or imbalances

- Triaxial Vibration Sensors: Captures vibration data in three axes for comprehensive analysis

- Wide Frequency Range: Covers a broad range of vibration frequencies, including low-frequency vibrations indicative of unbalance and high-frequency vibrations indicating bearing wear or gear defects

- High Sensitivity and Accuracy: Provides precise vibration measurements for accurate fault detection

- Fast Data Acquisition Rate: Enables real-time monitoring of vibration events

- Internal Data Storage: Stores vibration data for further analysis and historical trend tracking

- RS-485 Modbus Communication: Integrates seamlessly with SCADA and DCS systems for centralized monitoring and control

-

9199-00002 A6120

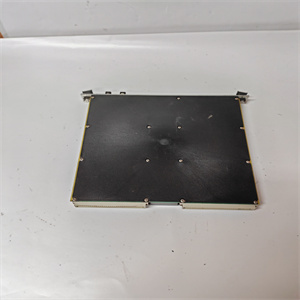

Dimensions:

- Height: 114 mm (4.50 in)

- Width: 165 mm (6.50 in)

- Depth: 22.5 mm (0.89 in)

Weight:

- Approximately 0.4 kg (0.88 lb)

Series:

- Emerson AMS Series

Features:

- Comprehensive vibration monitoring: Provides a complete picture of machinery health by monitoring vibration levels in three axes

- Advanced signal processing: Utilizes sophisticated algorithms to extract meaningful information from vibration data, enabling early detection of faults

- Alarm and warning capabilities: Generates alarms or warnings when vibration levels exceed preset thresholds, alerting operators to potential problems

- Data storage and analysis: Stores vibration data internally and facilitates data analysis for trending and root cause identification

- Modbus communication: Enables integration with SCADA and DCS systems for centralized monitoring and control

- Rugged construction: Withstands harsh industrial environments

Function:

The Emerson A6120 9199-00002 Vibration Monitoring Module serves as a valuable tool for predictive maintenance programs, helping to prevent unplanned downtime and extend the lifespan of machinery. It continuously monitors vibration levels in rotating equipment and analyzes the data for abnormalities.

The module’s triaxial vibration sensors capture vibration data in three axes (vertical, horizontal, and axial), providing a comprehensive assessment of machinery health. Its wide frequency range covers a broad spectrum of vibration frequencies, encompassing both low-frequency vibrations indicative of unbalance and high-frequency vibrations suggesting bearing wear or gear defects.

The A6120’s high sensitivity and accuracy ensure precise vibration measurements, enabling the detection of subtle changes in vibration patterns that may signal impending faults. Its fast data acquisition rate allows for real-time monitoring of vibration events, providing immediate insights into machinery health.

The module’s internal data storage capability facilitates the retention of vibration data for further analysis and historical trend tracking. This data can be used to identify patterns and trends that may indicate developing problems, enabling proactive maintenance measures before failures occur.

RS-485 Modbus communication enables seamless integration of the A6120 into SCADA and DCS systems, allowing for centralized monitoring and control of machinery health from a single location. Operators can remotely access vibration

9199-00002 A6120